High pressure, high voltage penetrator assembly

A penetrator, high-pressure technology, applied to electrical components, gas-filled/oil-filled cable accessories, circuits, etc., can solve problems such as operational failure, compressor or pump subsea facility collapse, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

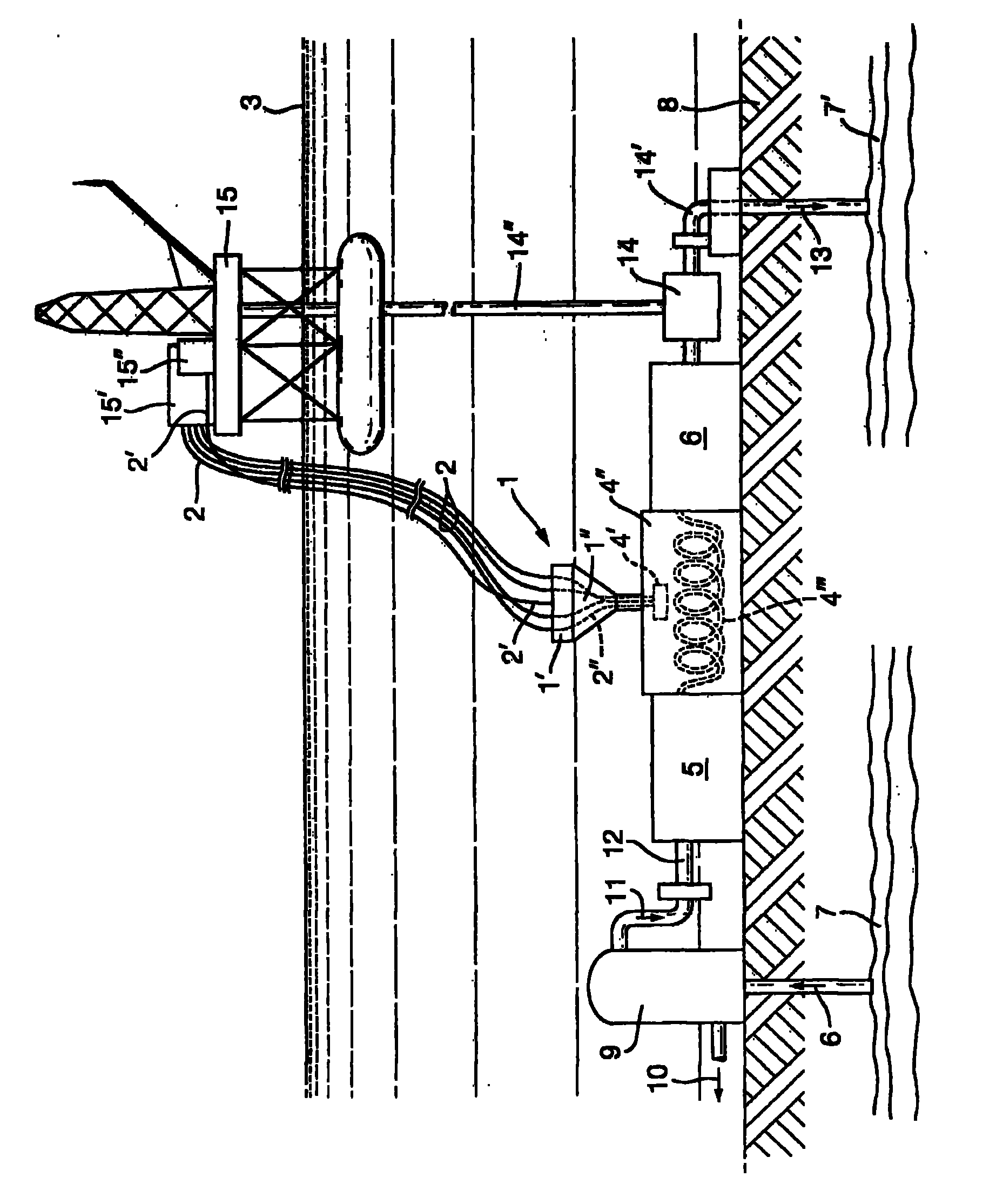

[0075] figure 1 A non-limiting example of a typical operating environment is shown for a penetrator assembly 1 having a power cable 2 and a signal cable 2' extending downward from a surface 3' of a sea 3, the power cable 2 is powered by a generator 15' on an offshore facility, such as an offshore platform 15 (not shown to scale relative to the compressor units 4, 5, 6 on the seabed 8 for simplicity). The signal cable 2' leads to a signal processing station 15" on the facility 15. The power cable 2 is relayed through the penetrator unit 1' of the assembly 1 and a further power cable 2" from the The penetrator unit 1' extends through the interior 1" of the assembly down to a motor connection terminal 4' inside the housing 4" of an electric motor 4 configured to drive an upstream mounted wet fluid compressor or pump 5 and downstream wet fluid compressor or pump 6.

[0076] The compressor or pump 5 receives fluid, such as gas 7' from a reservoir 7 below the seabed 8, which fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com