Developer unit for an electrophotographic printing device for printing on glass or ceramic material

A technology of electrophotographic printing and developing unit, which is applied in the field of toner supply and toner application device, electrophotographic printing equipment, and can solve problems such as inaccuracy and uneven application of toner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

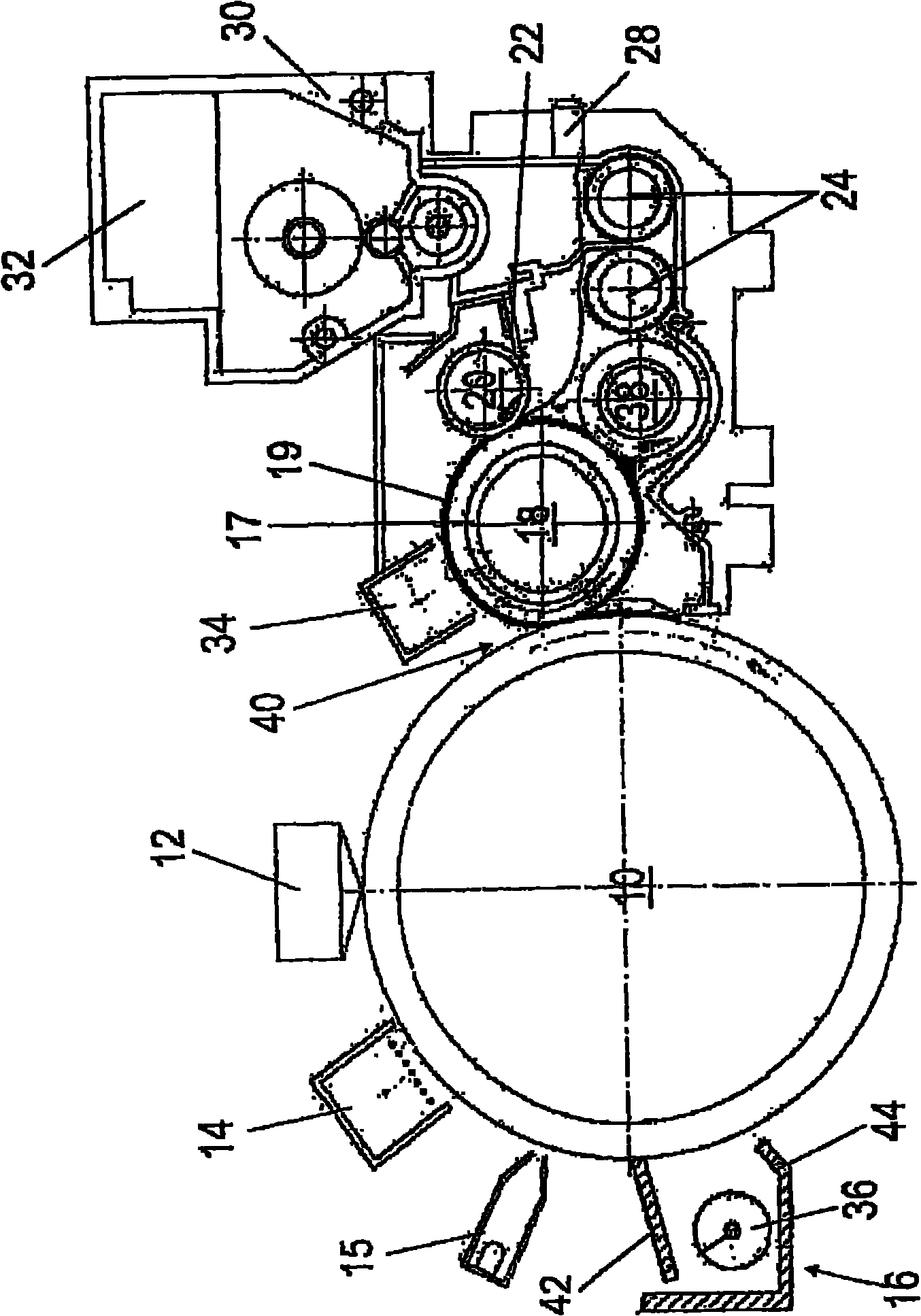

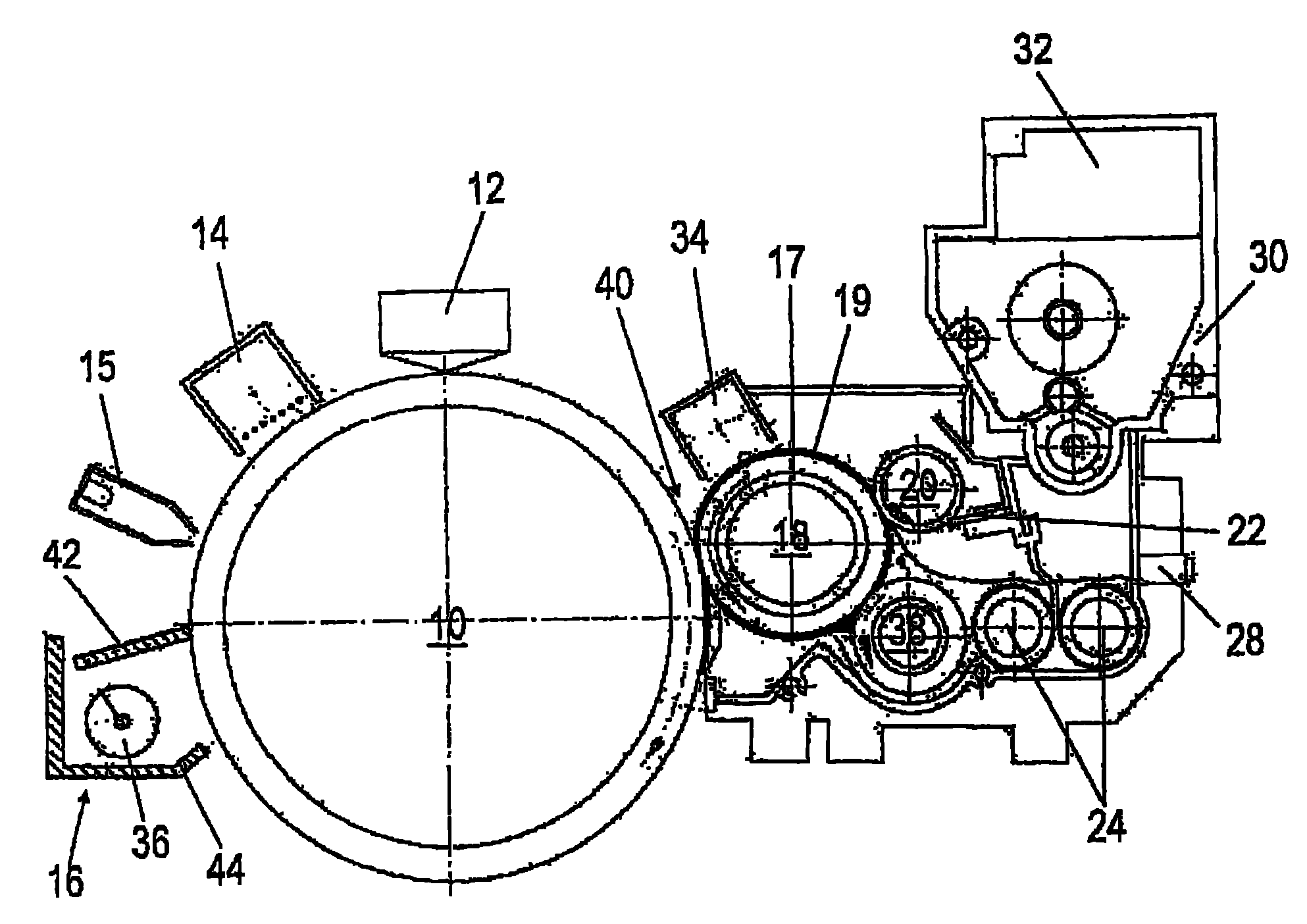

[0025] Via a toner attachment 30, which has an incorporated toner supply (not specifically shown), toner is conveyed from the toner cartridge to the area of two conveying and mixing screws 24 that rotate in opposite directions. The level sensor 28 reports the correct fill level to an electronic controller (not shown) of the printing apparatus. The electronic controller requests new toner as needed based on the sensor signal.

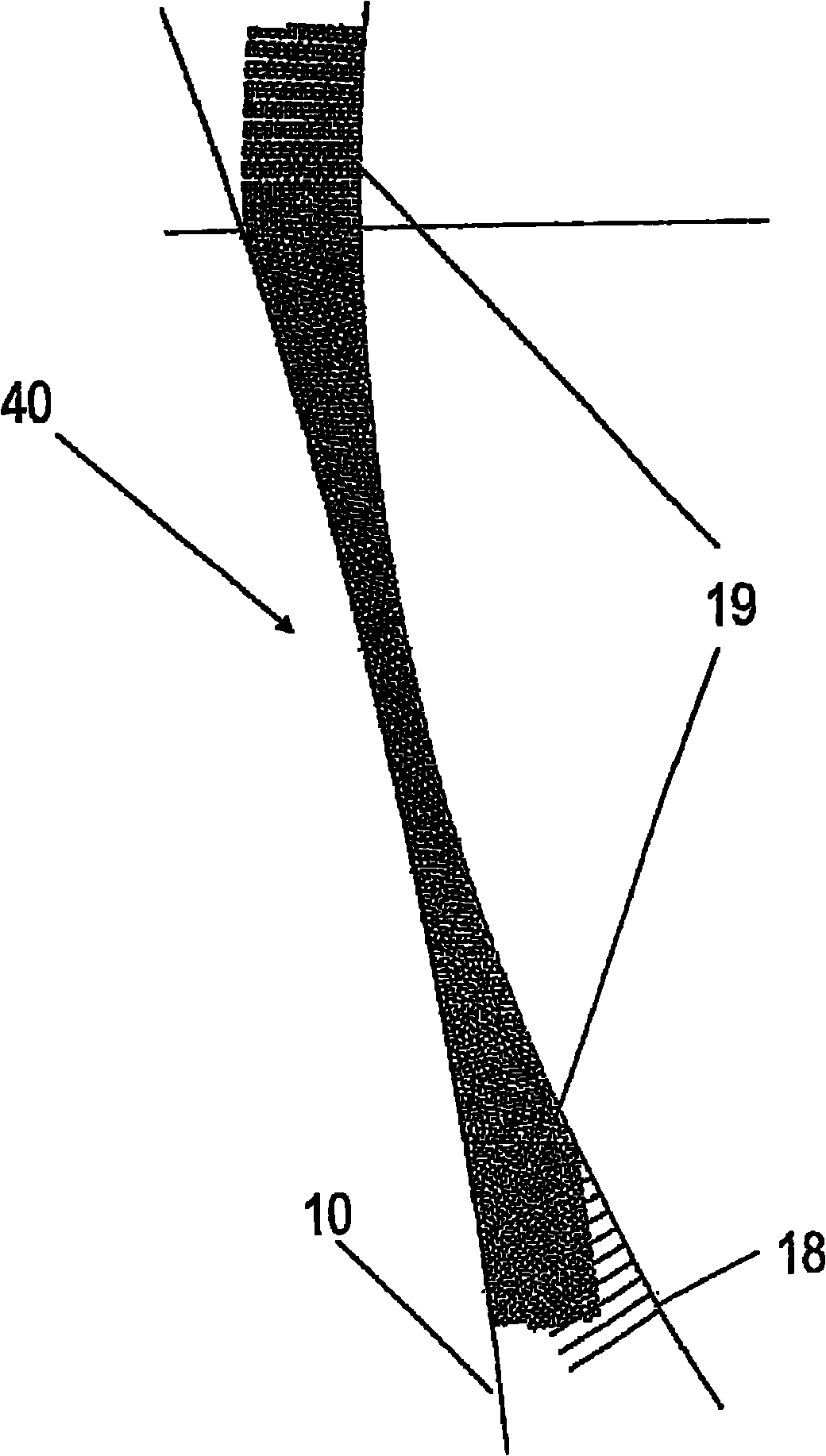

[0026] The single loop system formed by the conveying and mixing screw 24 conveys the toner to an application roller 38 which rotates in a counterclockwise direction. The applicator roller 38 consists essentially of a material that charges the coating 19 of the developer roller 18 by triboelectric charging, such as EPDM, NBR or PU foam. The applicator roll 38 has a width of about 960 mm, a diameter of about 50 mm, a Shore A hardness of about 50° and a perforation size of about 200 μm. Via the connection of the bias voltage to the inner mandrel, a bia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com