Rolling type rotate baking method and device of high-rating generator

A rotary baking and generator technology, applied in electromechanical devices, manufacturing motor generators, motor components, etc., can solve the problems of dead angle of temperature, loss of paint liquid, and few drying methods, etc., to ensure the quality of insulation and paint film. The effect of homogenizing and increasing the filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

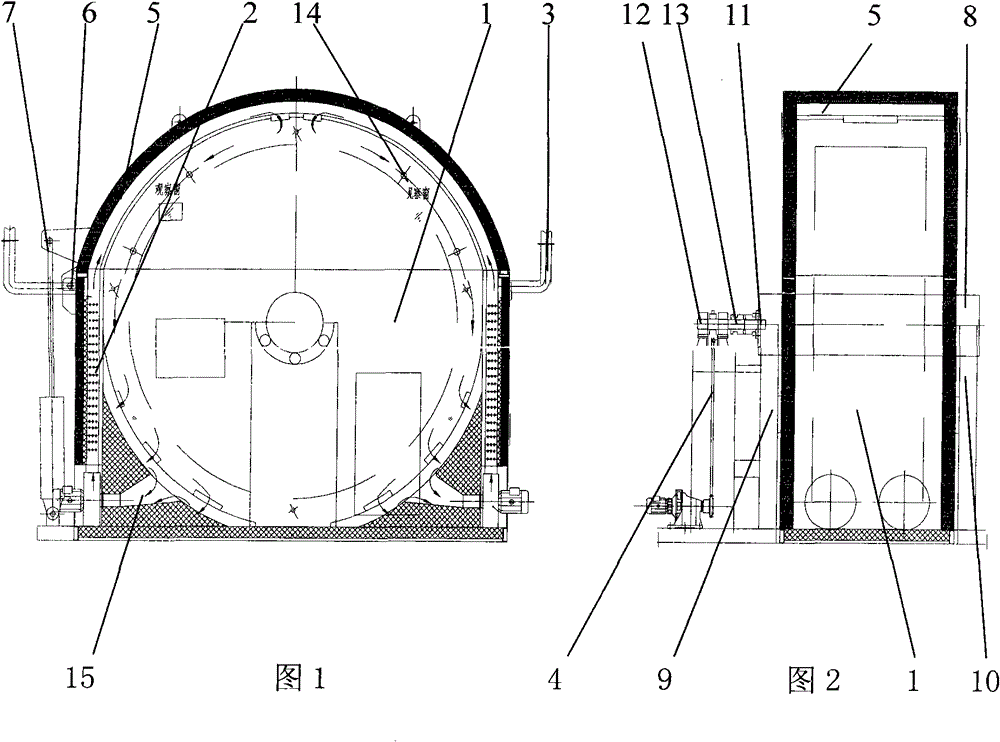

[0011] as attached Figure 1-2 As shown, the present invention is a large-scale generator rotary roasting method, which is to place the large generator on a rolling rotary roasting device, and use the rolling rotary roasting of the rolling rotary roasting device to roast the large generator. The rolling rotation refers to placing the generator to be dried in a rolling rotary roasting device with a rotatable part, and installing the generator to be dried on the rotating part of the rolling rotary roasting device, and It can rotate together in the rolling rotary roasting device when the rotating shaft of the rotating part of the rolling rotary roasting device rotates; on the fixed part of the rolling rotary roasting device, a heating element is arranged according to the spatial position of the rotating part of the rolling rotary roasting device, When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com