Composite excitation generator rotor

A generator rotor and compound excitation technology, which is applied to the rotating parts of the magnetic circuit, the manufacture of the stator/rotor body, the shape/style/structure of the magnetic circuit, etc., can solve the problems of inconvenient assembly, easy throwing of the magnetic steel, unsafe etc. problem, achieve the effect of improving work efficiency and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

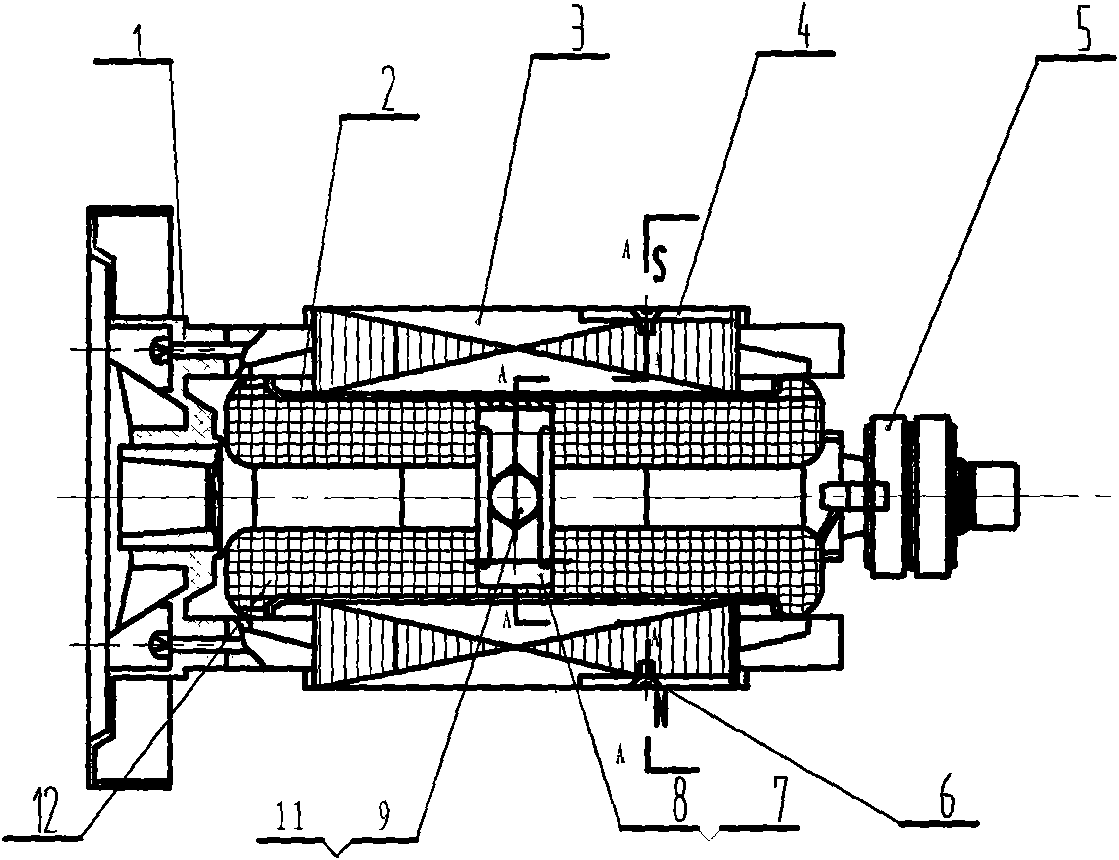

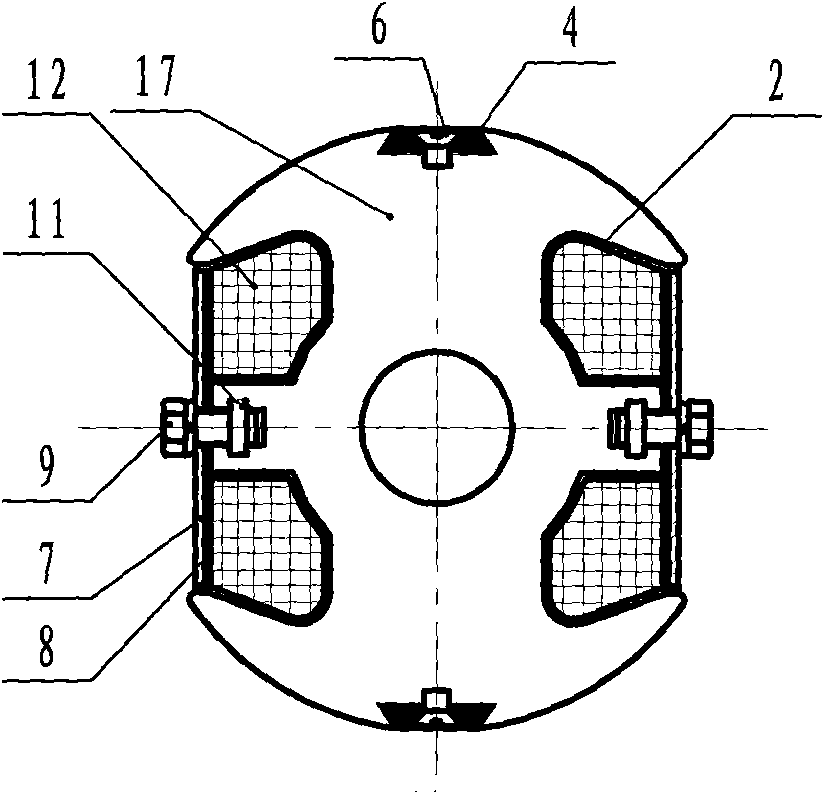

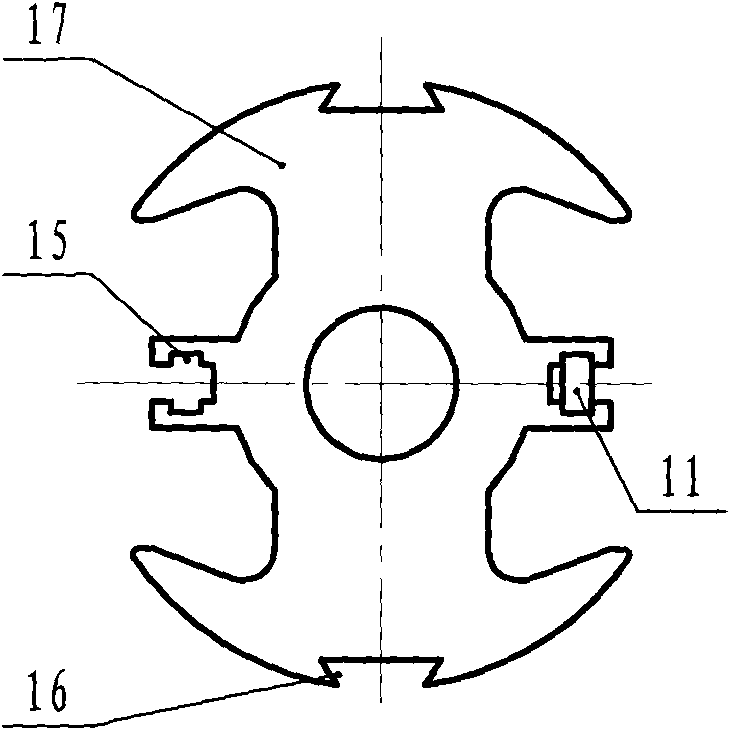

[0015] Describe the present invention in detail below in conjunction with accompanying drawing:

[0016] Such as Figure 1-3 As shown, the composite excitation generator rotor, the rotor core 3 is composed of several rotor cores 17, and the rotating shaft is press-fitted in the central hole of the rotor core 3. The dovetail-shaped magnetic steel groove 16 provided on the rotor core 3 is equipped with a magnetic steel 4. In order to ensure that the magnetic steel 4 will not be thrown out during high-speed rotation, the assembly structure of the magnetic steel 4 is adopted in the dovetail-shaped magnetic steel A screw hole is formed at the bottom center position of the groove 16, and a countersunk screw 6 is correspondingly formed on the magnetic steel 4, and the magnetic steel 4 is fastened on the dovetail magnetic steel groove 16 in the hole. The enameled wire 12 is wound in the frame groove of the coil frame 2, the nut 11 is put in the nut groove of the screw nut groove 15 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com