Full-split single pore sound wave test device and debugging method thereof

A single-hole sound wave and testing device technology, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves for material analysis, analyzing materials, etc., can solve problems such as water leakage, inability to inject water, and loss of meaning in water coupling test results. To achieve the effect of expanding the detection range and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

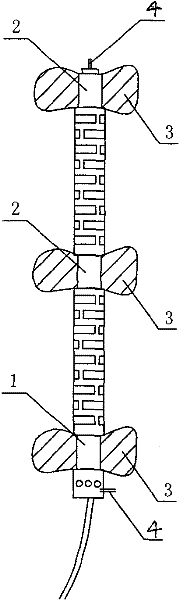

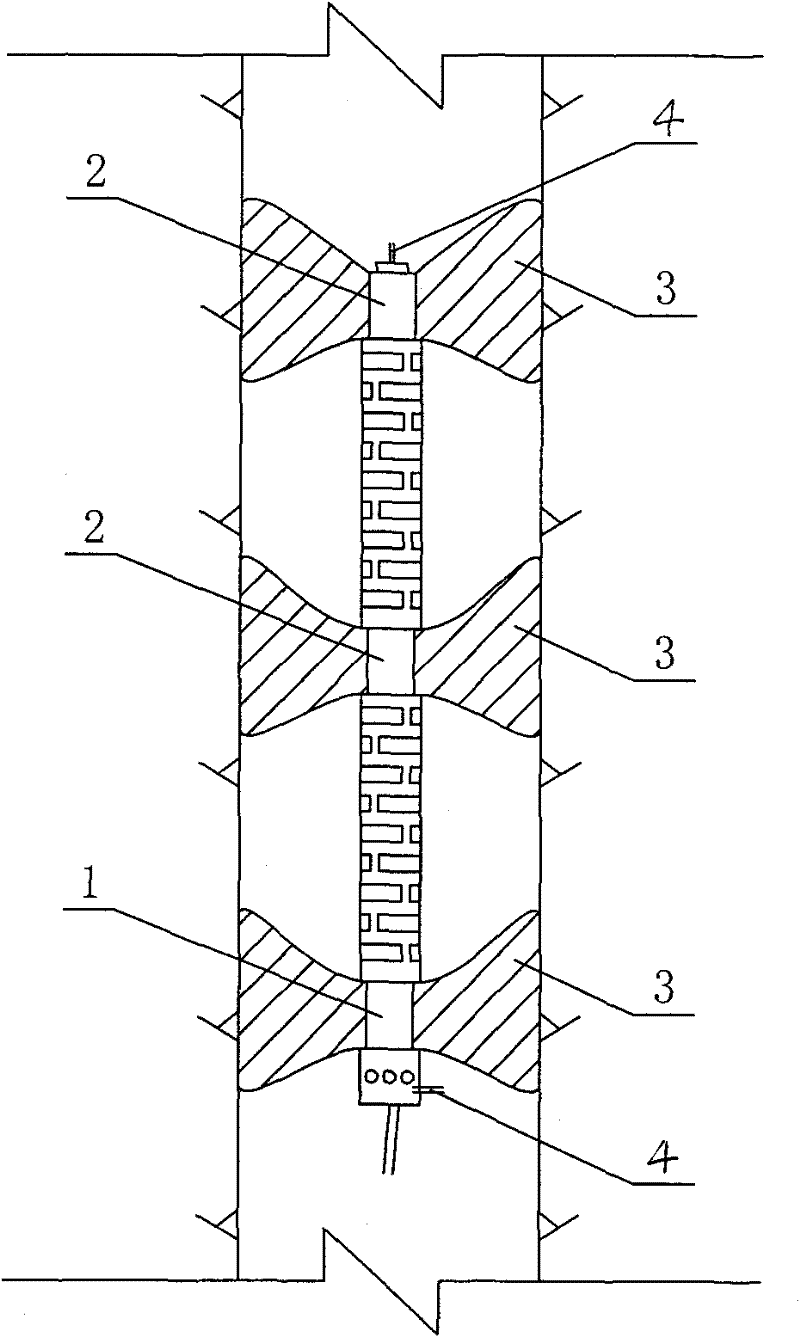

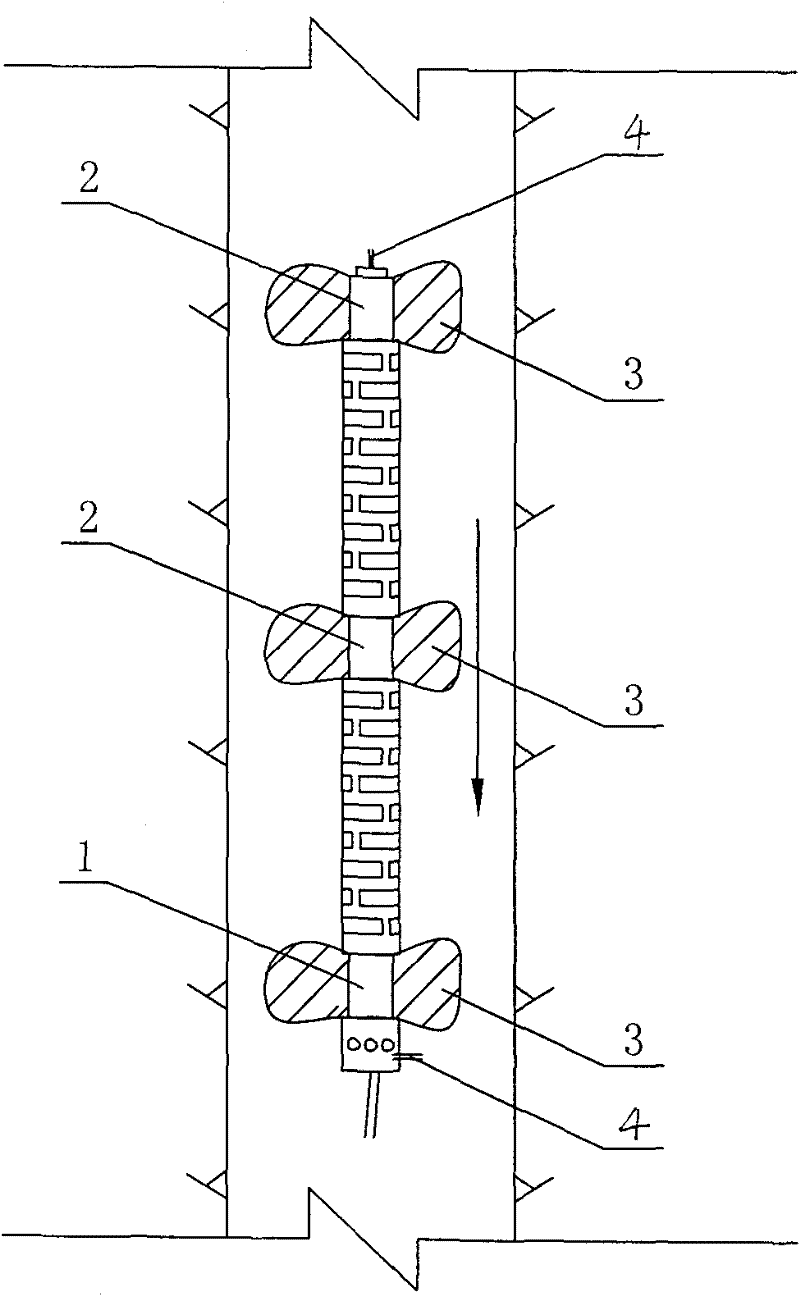

[0029] Embodiment 1: as Figure 1 to Figure 3 As shown, the acoustic wave testing device of this embodiment adopts a double-receiving type, including a detection probe, a transmitting transducer 1 is installed at the bottom, a receiving transducer 2 is respectively installed at the top and the middle, and two receiving transducers 2 The distance between them is 20cm, and at the same time each transmitting transducer 1 and receiving transducer 2 are wrapped with mutually independent bladders 3, and each transmitting transducer 1 and receiving transducer 2 are separated from each other, which solves the problem of When the rock mass condition is poor, the acoustic wave velocity of skin 3 interferes with the real rock mass acoustic velocity. Each bladder 3 is equipped with its own independent thin tube for water injection, and the thin tube for water injection doubles as an exhaust pipe at the same time. Before use, squeeze the leather bag 3 with your hands to discharge the gas ...

Embodiment 2

[0039] Embodiment 2: as Figure 4-Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that an independent air bag 5 is provided outside each skin bag 3, and the centers of each air bag 5 are located on the same straight line. Before the detection probe is put into the detection hole, the air bag 5 is in a contracted state. After the detection probe is put into the predetermined position in the detection hole, the air bag 5 is inflated through the respective inflation tubes of the air bag 5, so that the air bag 5 is inflated, and the water-filled skin bag 3 is pushed. Closely coupled with the detection hole wall, the acoustic wave detection can be carried out.

[0040] The implementation steps of this embodiment are as follows:

[0041] a1, b1, c1 steps are the same as steps a, b, c in embodiment 1;

[0042] d1. Inflate the airbags 5 located at the top, middle and bottom of the detection probe in turn, start sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com