Double hobbing cutter rock hobbing comprehensive test bed

A comprehensive test bench and double hob technology, applied in the direction of testing machinability, etc., can solve the problem that the impact of tool wear on rock breaking efficiency cannot be measured in real terms, and achieve strong impact resistance, high feeding accuracy, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

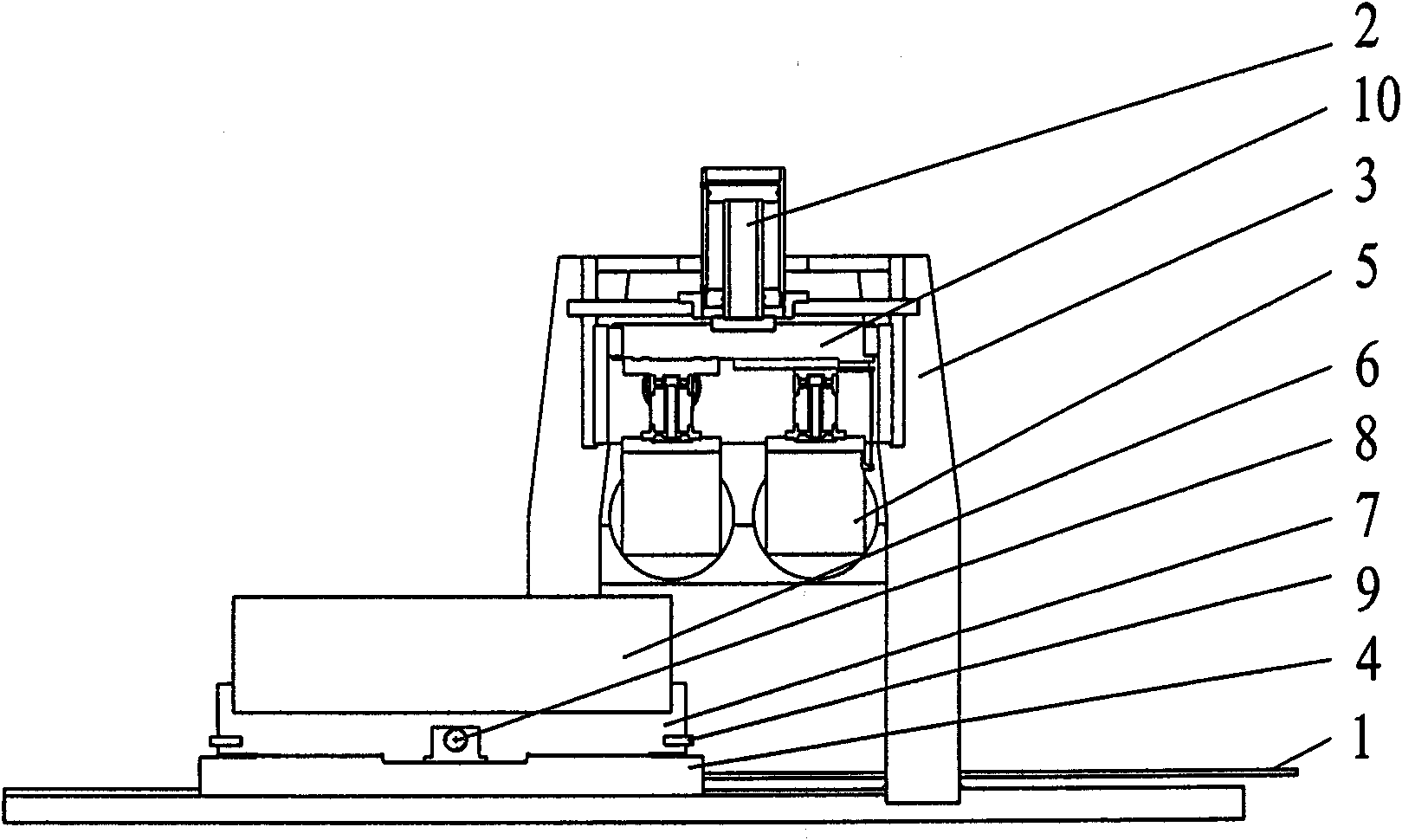

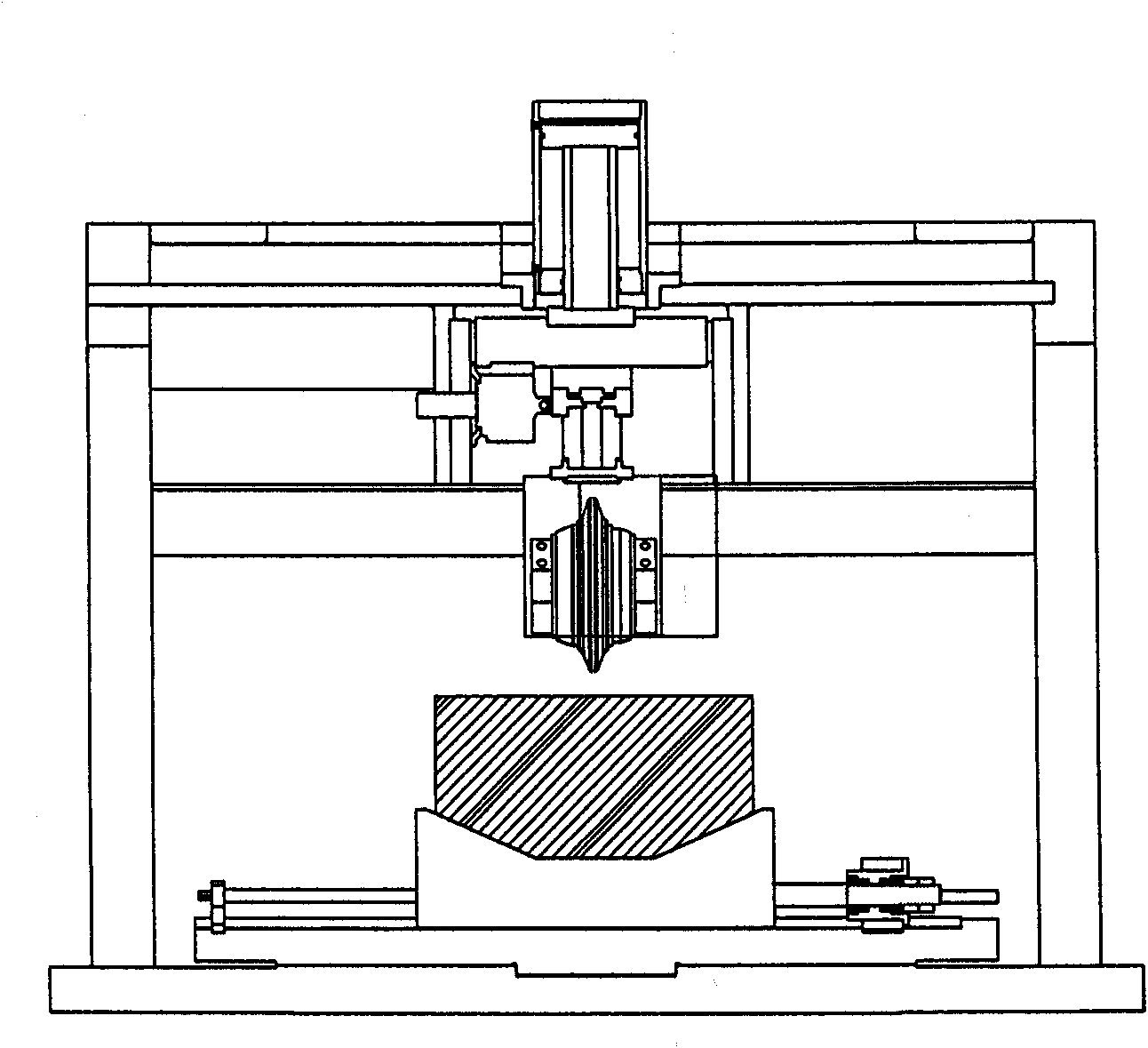

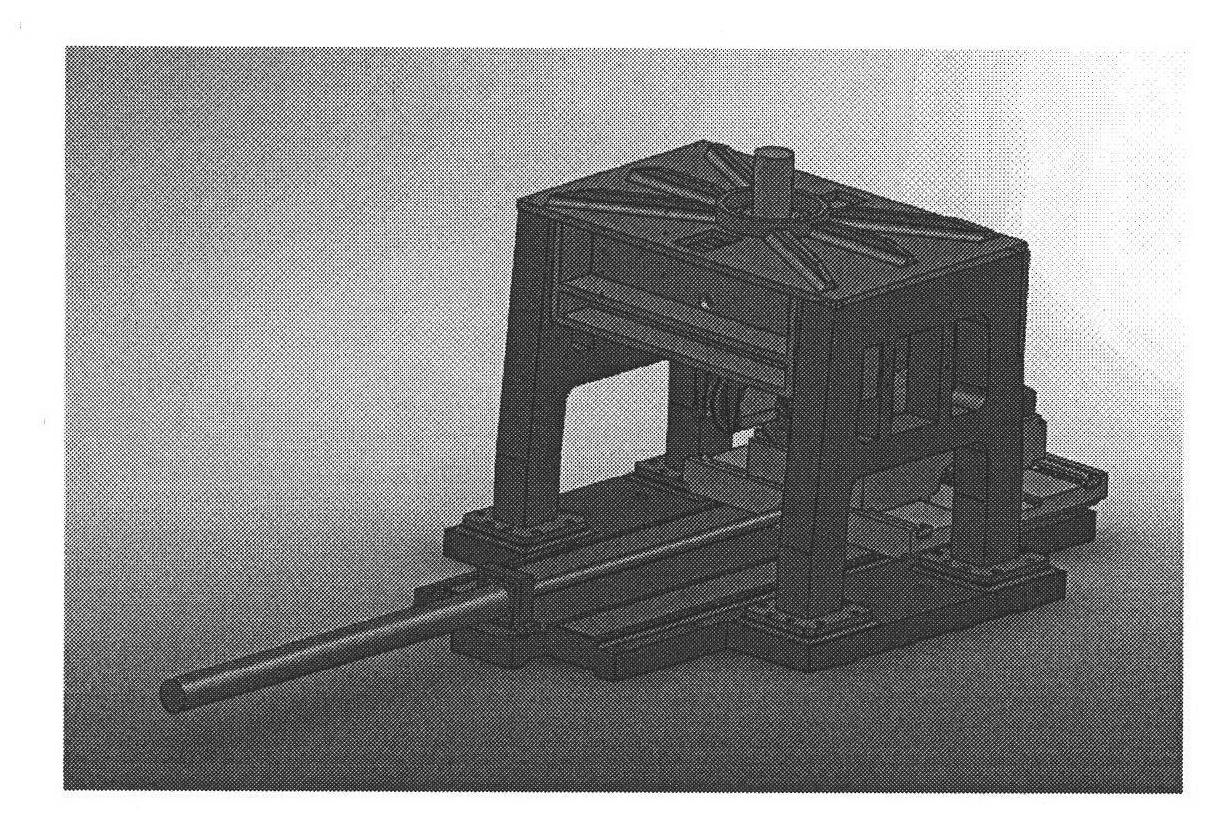

[0018] The present invention will be described in detail below with reference to the accompanying drawings.

[0019] In the experimental process of the present invention, the movement of the workpiece is used to drive the hob to rotate around its own axis. The hydraulic system pulls the workpiece to reach the set speed, and the penetration adjustment of the hob depends on the tool hydraulic system. The adjustment of the distance between the workpiece and the tool is through the respective adjustment mechanism, and the tool is positioned mechanically after adjustment, which is simple and reliable.

[0020] The gist of the present invention lies in its structure and principle. Its working principle is that under the action of the cutter hydraulic system, the base of the cutter head drives the hob to move up and down as a whole, and produces a certain degree of penetration into the rock surface. The parts produce movement and displacement, and the movement of the worktable driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com