Thread-laying device

A wire and laying technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as danger, and achieve the effect of quick disassembly and stable gap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

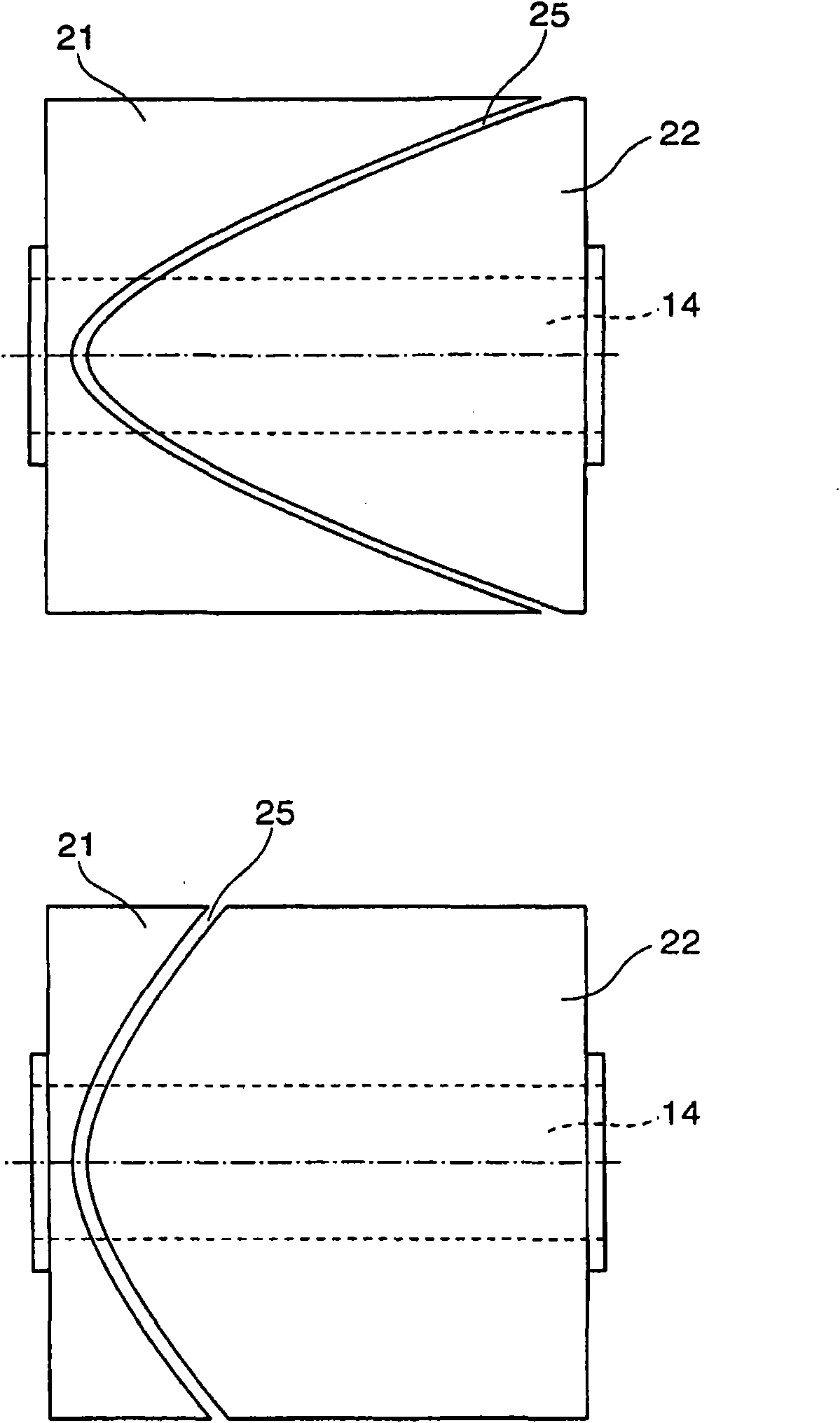

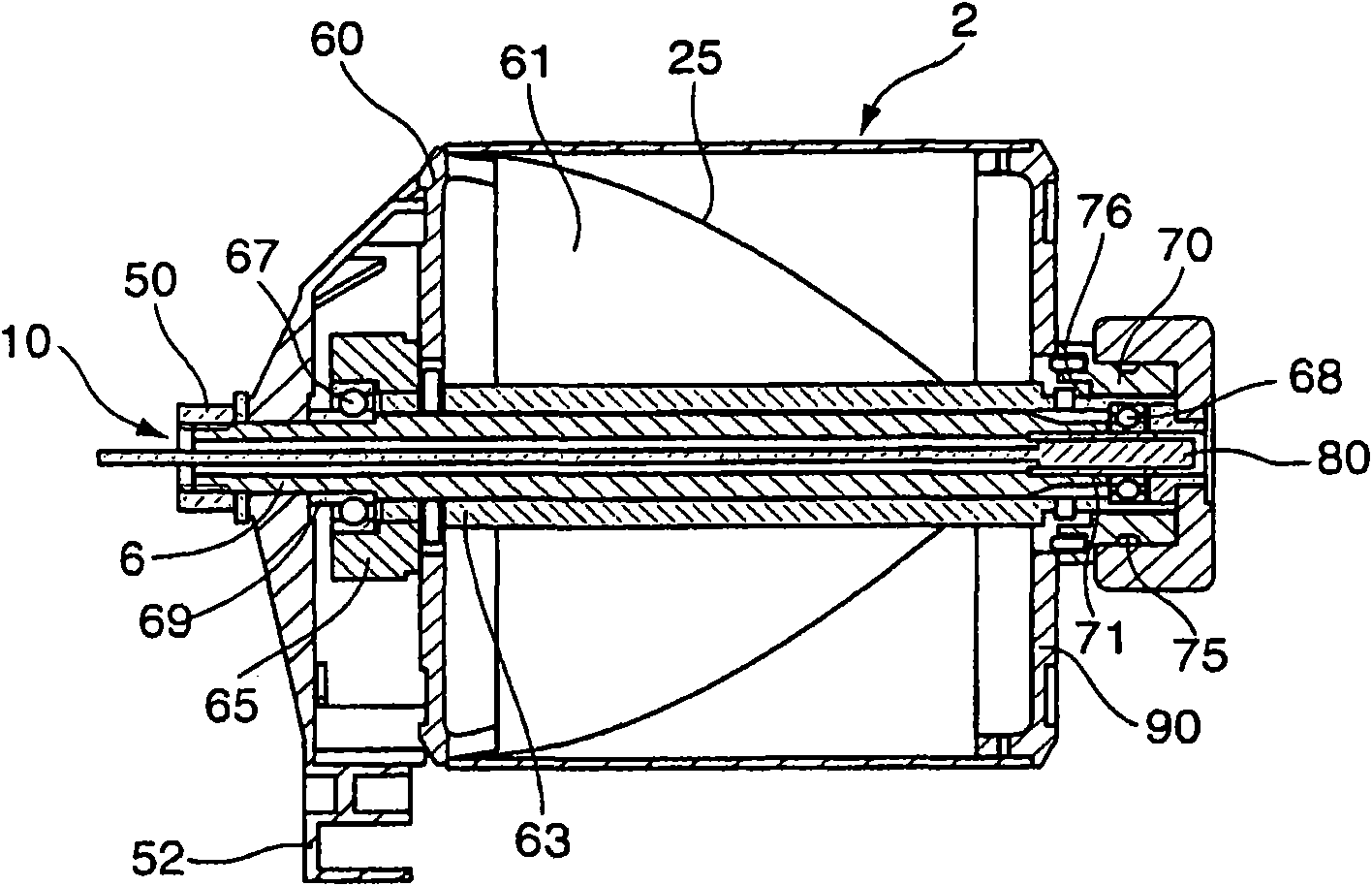

[0029] The illustrations in the individual figures represent the content according to the invention in a very simplified manner and are not to be understood as being true to scale. The individual components according to the content of the invention are shown in such a way that their structures can be well visualized.

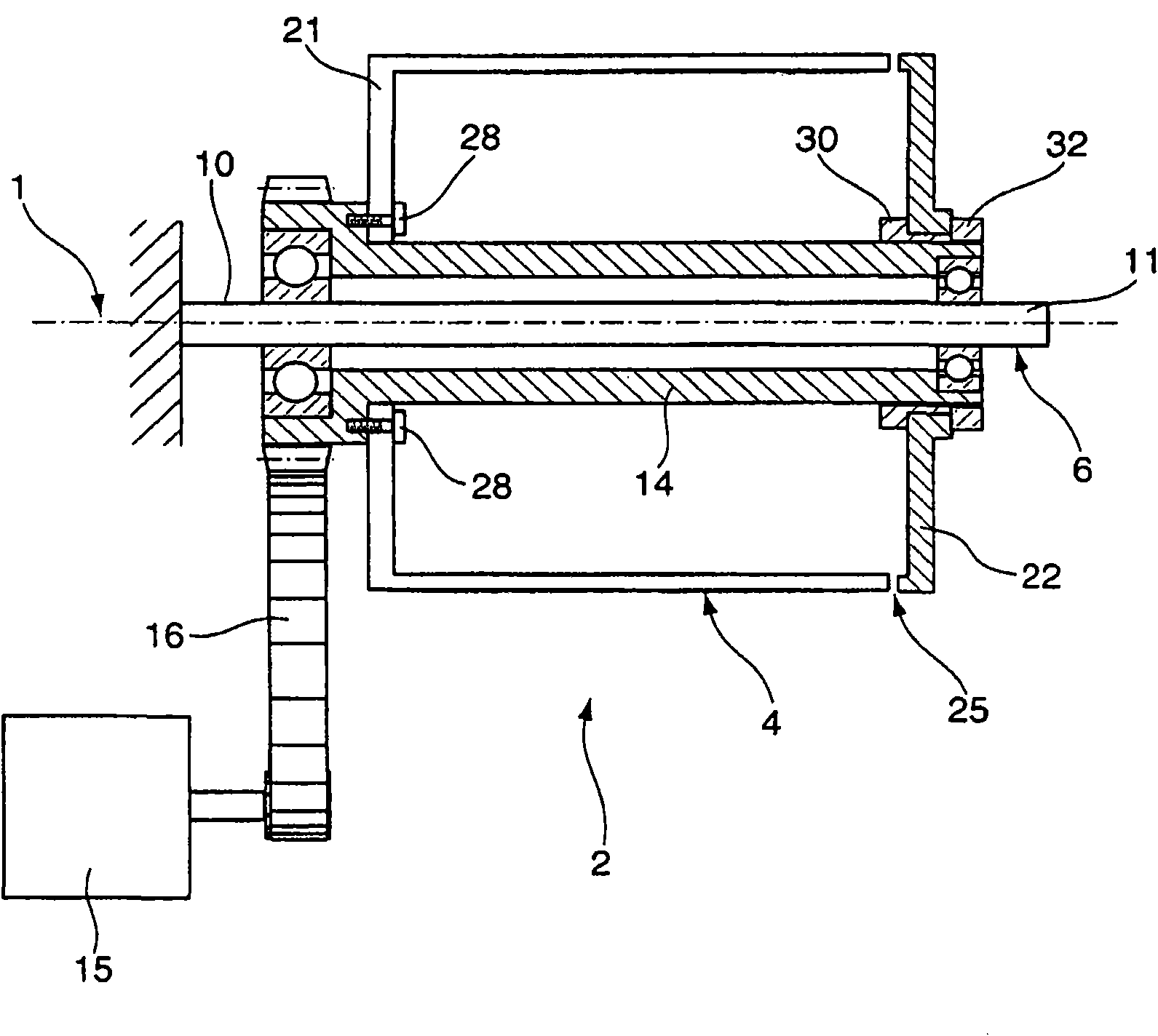

[0030] figure 1 The thread laying device according to the invention is shown in transverse section. The thread depositing device has a depositing drum 2 rotatable by a drive about an axis of rotation 1 , which forms a cylindrical surface 4 . The axis of rotation 1 is formed by a shaft 6 with one two shaft ends. The shaft 6 is rigidly mounted on the wire laying device. One shaft end is formed as an assembly shaft end 10, so that the shaft 6 is mounted on the wire laying device via the assembly shaft end 10, and the second shaft end 11 is formed as a free shaft end to form a single side for the laying drum 2. support. The laying drum 2 has a hollow shaft 14 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com