Nuclear grade valve electric device

A valve electric, nuclear-level technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problem of unstable operation of valve electric device, failure to guarantee safe and reliable operation, lack of torque overload protection and stroke limit bit functions etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

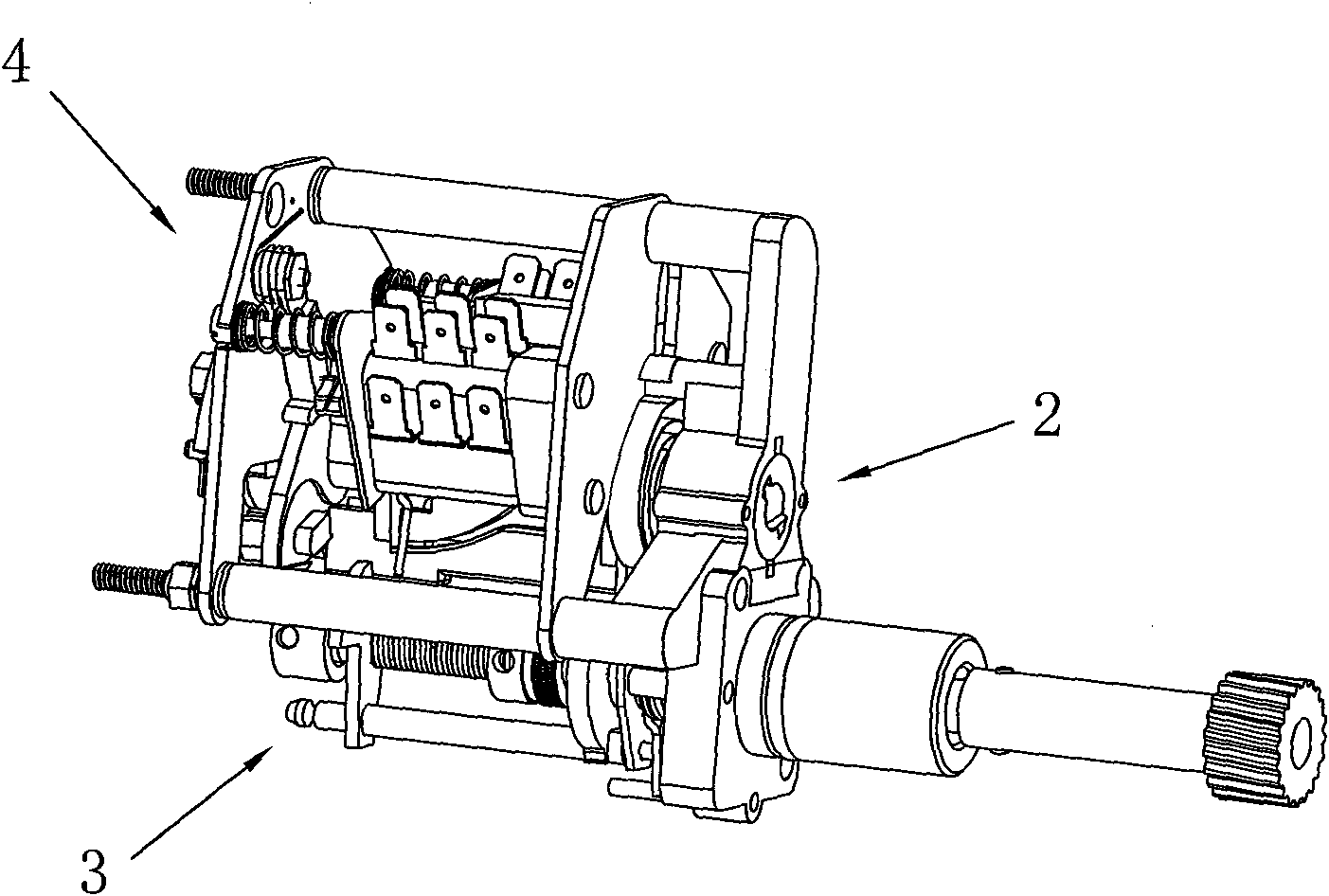

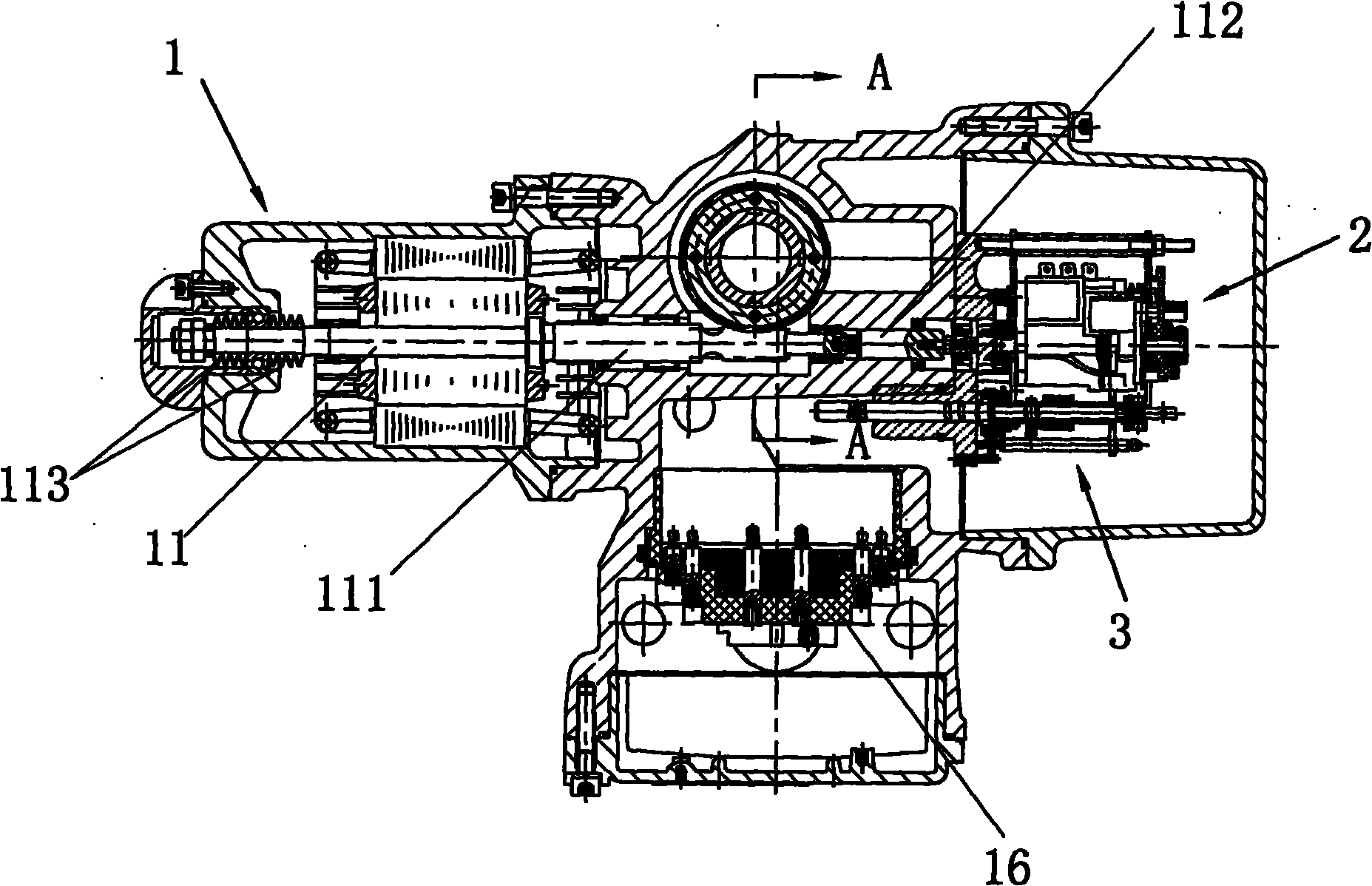

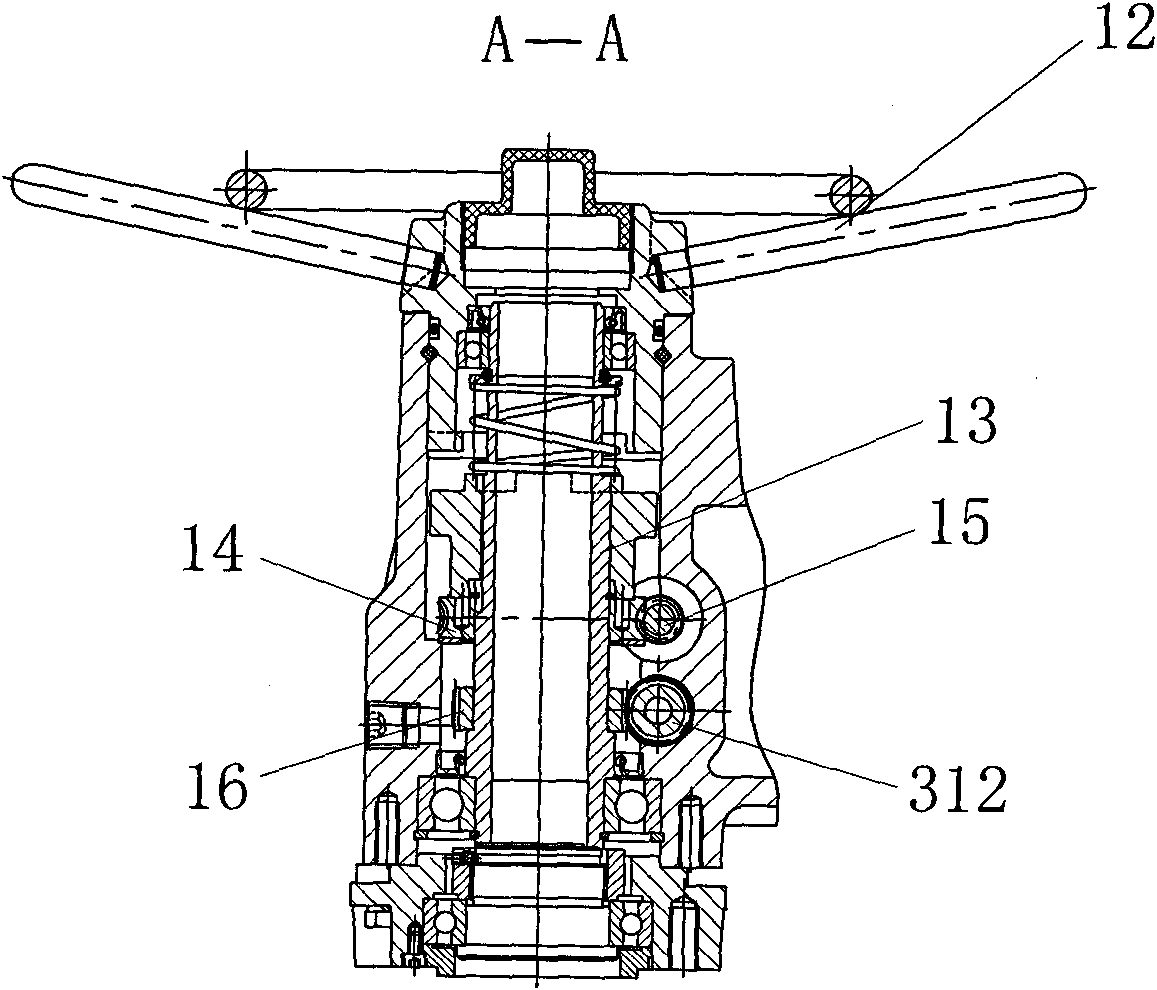

[0028] Such as figure 1 , 2 , 3, the present embodiment includes a casing 1, a hand wheel 12, and a motor 11, a worm 15, a worm wheel 14, a drive shaft 13 and a terminal block 16 arranged in the casing 11, and the hand wheel 12 is fixed with the drive shaft 13 , the worm wheel 14 is sleeved on the drive shaft 13, one end of the worm 15 is linked with the worm wheel 14, and the other end is linked with the motor output shaft 111, the worm 15 rotates together with the motor output shaft 111, and the worm 15 transmits the torque output by the motor output shaft 111 Give the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com