Feather type vertical shaft wind wheel

A vertical-axis, pitch-variable technology applied to vertical-axis wind rotors. It can solve problems such as high resistance torque and difficulty in self-starting, and achieve the effects of enhancing performance, enhancing adaptability to harsh weather environments, and prolonging effective running time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

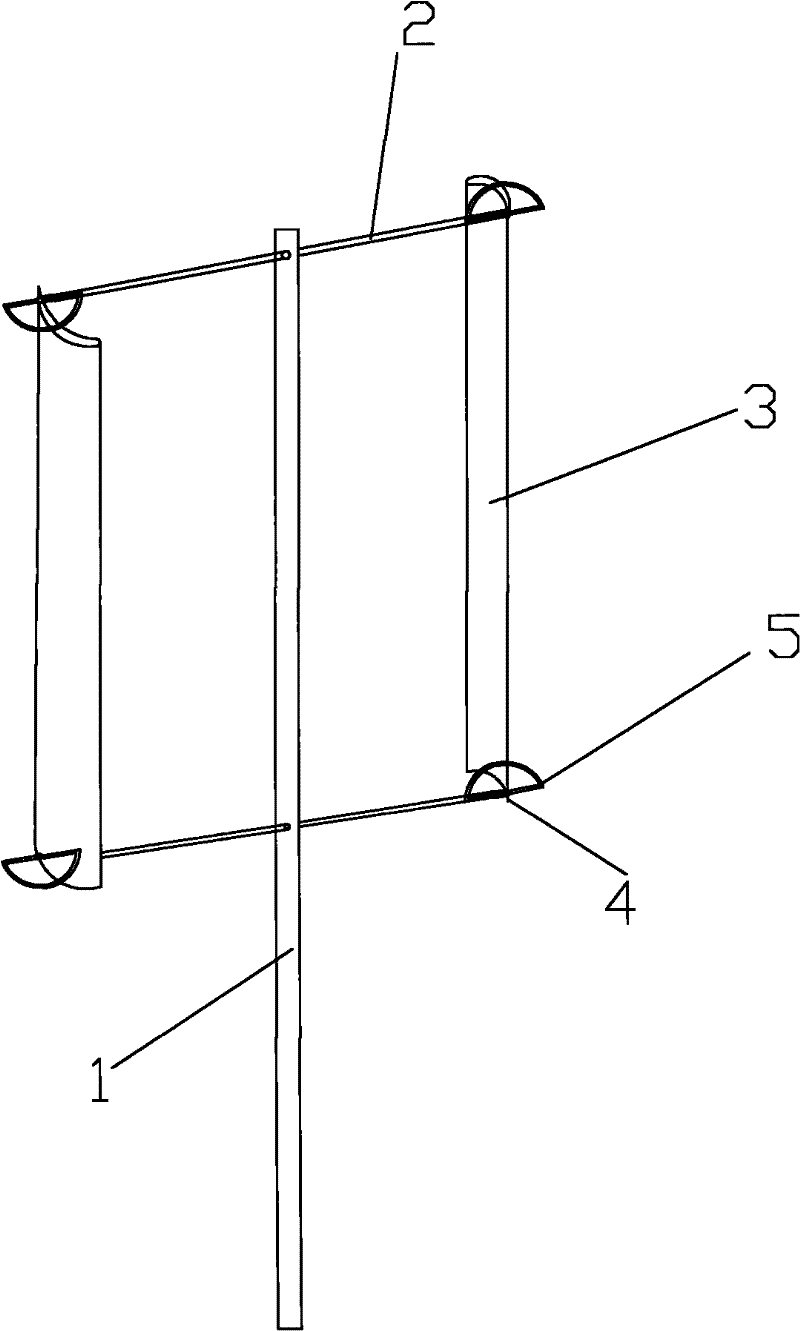

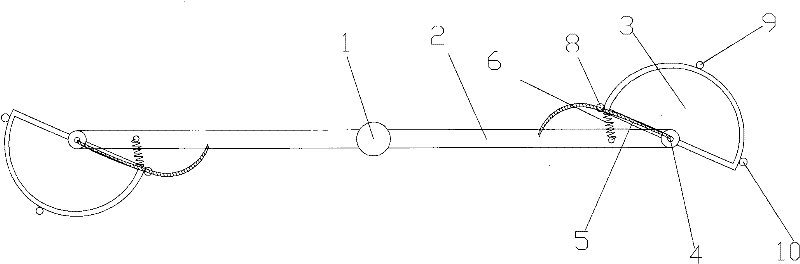

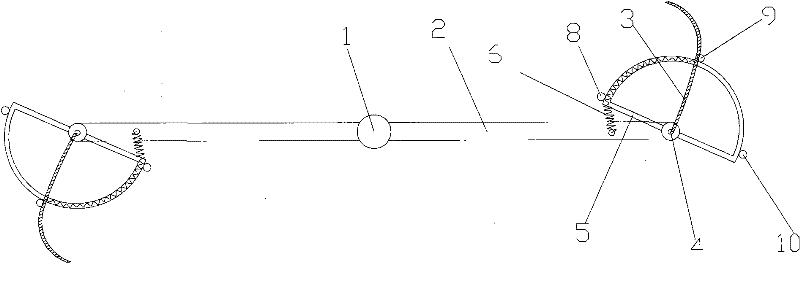

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention is a vertical axis wind wheel, including a wind wheel shaft 1, two or more pairs of blade brackets 2 are installed on the wind wheel shaft 1, and straight blade lift type blades 3 are arranged between each pair of brackets 2. Along the chord length direction of the blade airfoil, the trailing edge of the blade is fixed on the blade rotating shaft 4 , and a blade pitch controller 5 is arranged at both ends of the blade rotating shaft 4 . The blade pitch control device 5 includes a positioning plate, a blade return spring 6 and a positioning pin 11, and the positioning pins 11 are arranged on the circumference of the positioning plate, and there are at least three. In this embodiment, there are three positioning pins 11, They are respectively set at three positions of blade pitch angles of 0°, 90° and 180°. The blade pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com