Method for exploiting coal bed methane (CBM) by water transportation and pressure relief in butted well

A coalbed methane and migration technology, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve problems such as poor effect and restrict coalfield development, and achieve the effect of high-efficiency production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with an embodiment (accompanying drawing):

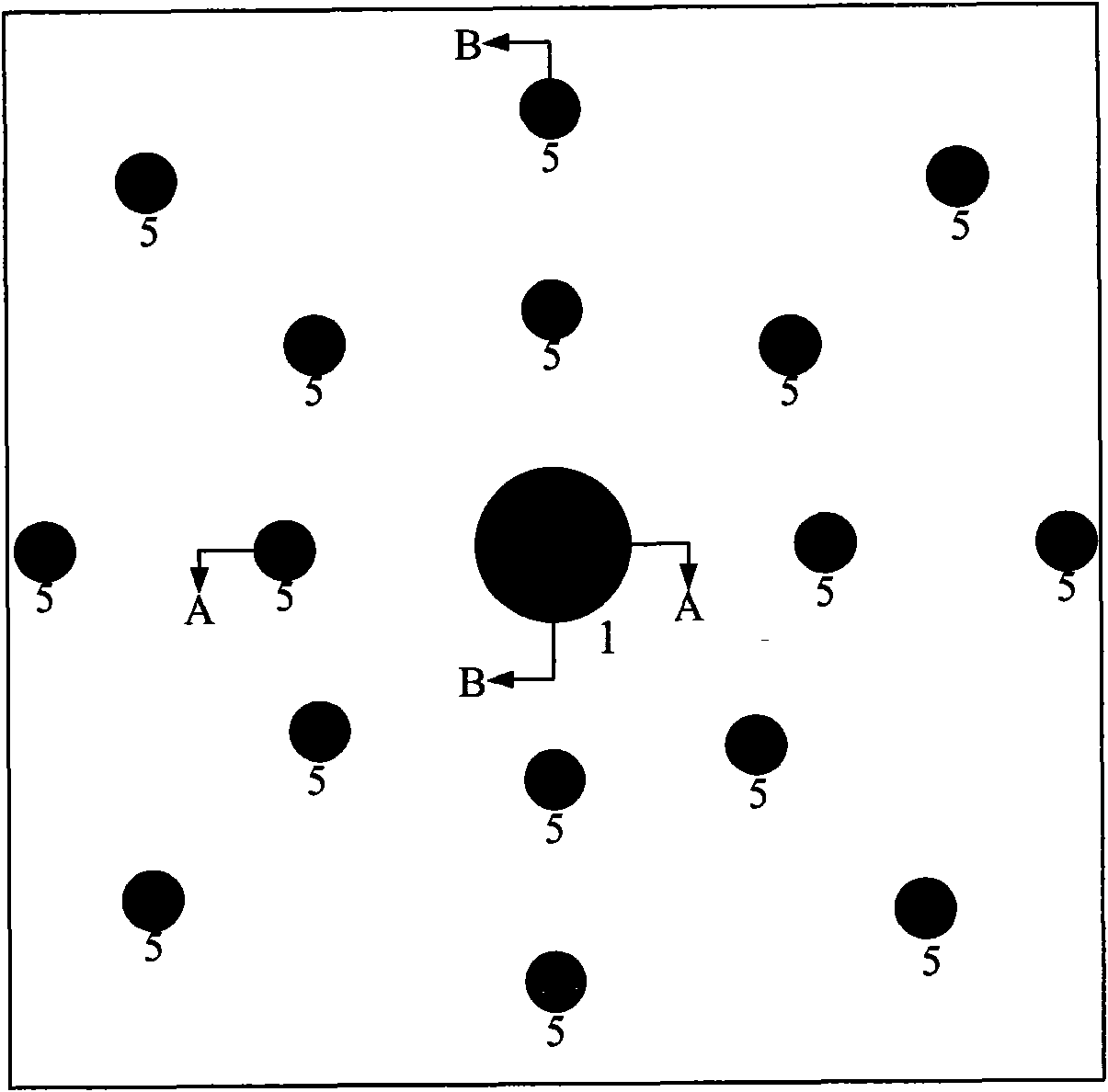

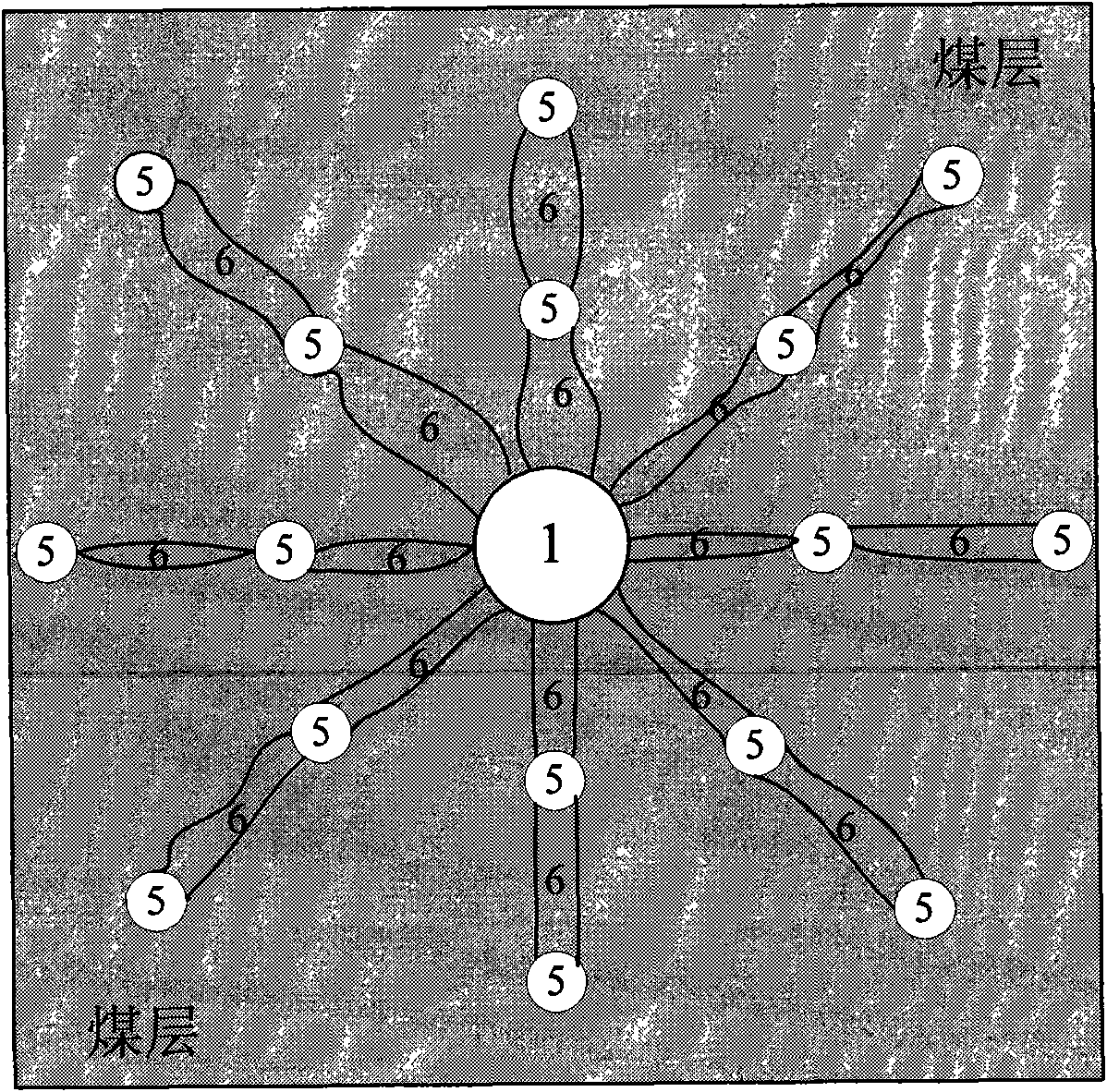

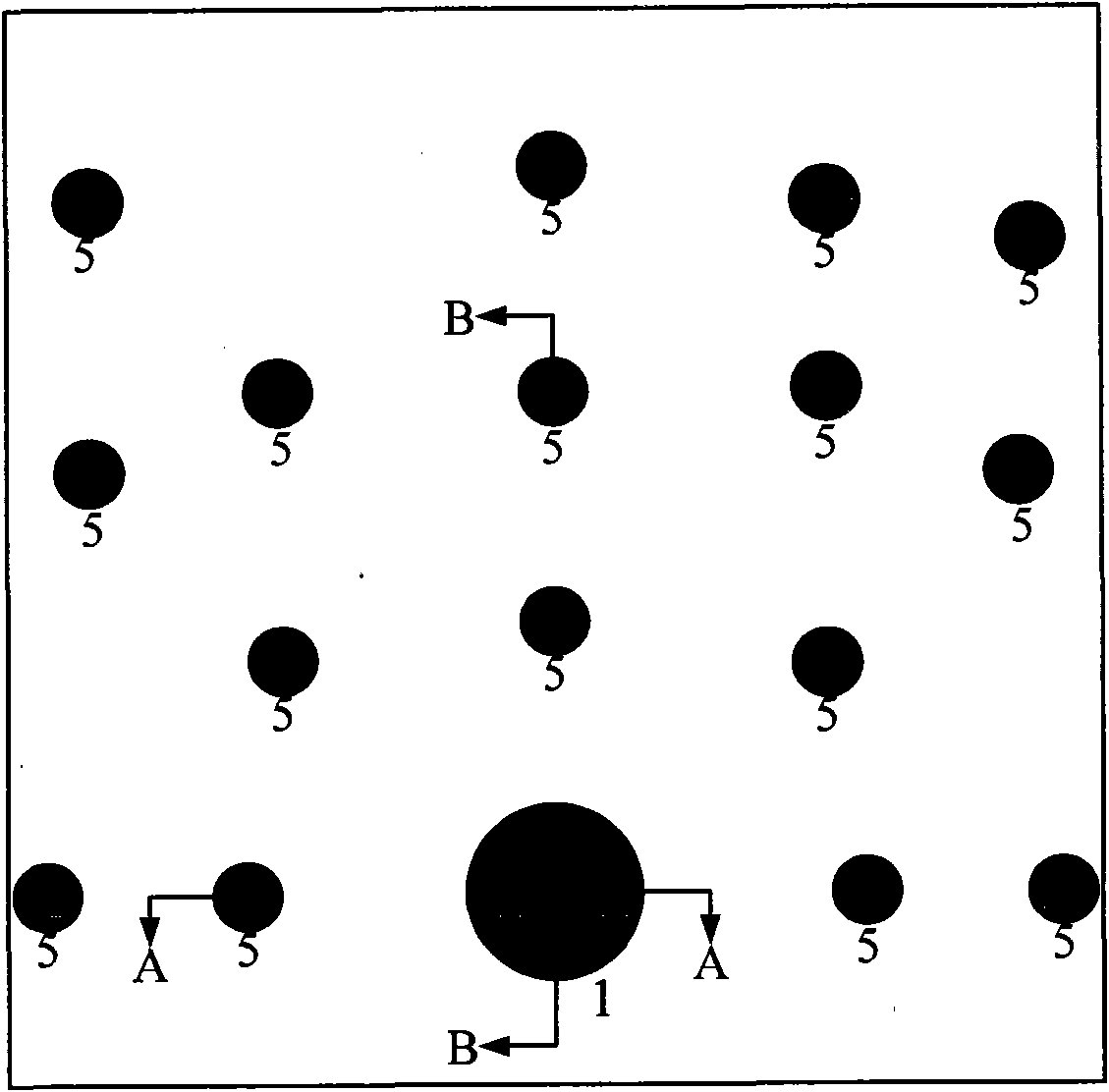

[0027] Such as Figure 5 , Image 6 As shown, the method for exploiting coalbed methane by hydraulic migration of butt joint wells according to the present invention includes a gas outlet well 1 for coal discharge, a cave 4 , a water injection well 5 , and a pressure relief space 6 . The specific implementation steps are as follows:

[0028] (1) Set the coal water discharge well 1. The well is drilled from the surface 2 to the coal seam 3 or below the coal seam 3, and is used to collect the coal-water mixture and discharge the coal-water mixture in a concentrated manner, while collecting coal-bed methane.

[0029] (2) Set the water injection and gas outlet well 5. The well is drilled from the ground 2 to the coal seam 3; the water injection well 5 is kept at an appropriate distance from the coal discharge well 1.

[0030] (3) dig holes. Use the known t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com