Torsion crossed welding intersected node of steel component with rectangular cross section

A technology with rectangular cross-section and intersecting nodes, which is applied in the direction of building construction and construction, can solve the problems of reducing structural rigidity, increasing structural steel consumption, and large structural deformation, so as to reduce self-weight, steel consumption and cost The effect of increasing and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

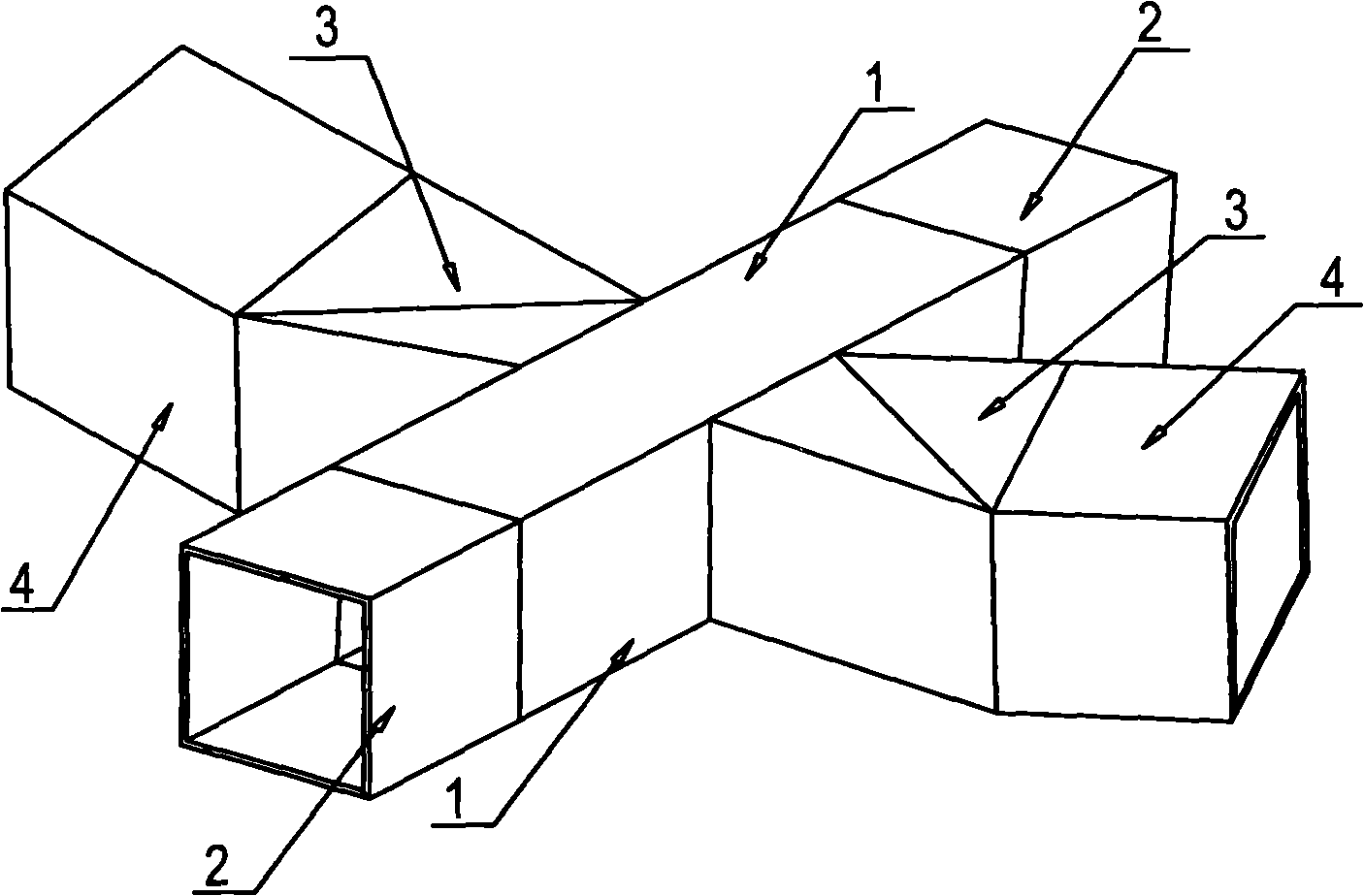

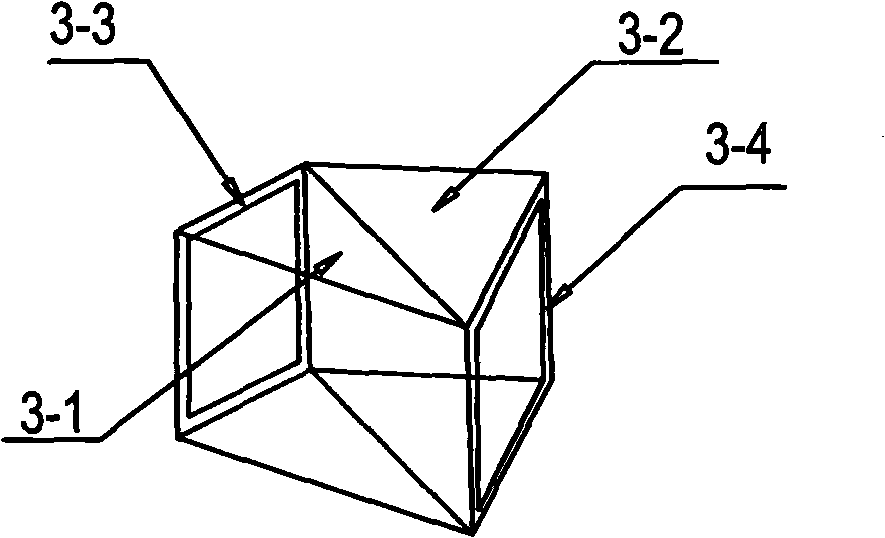

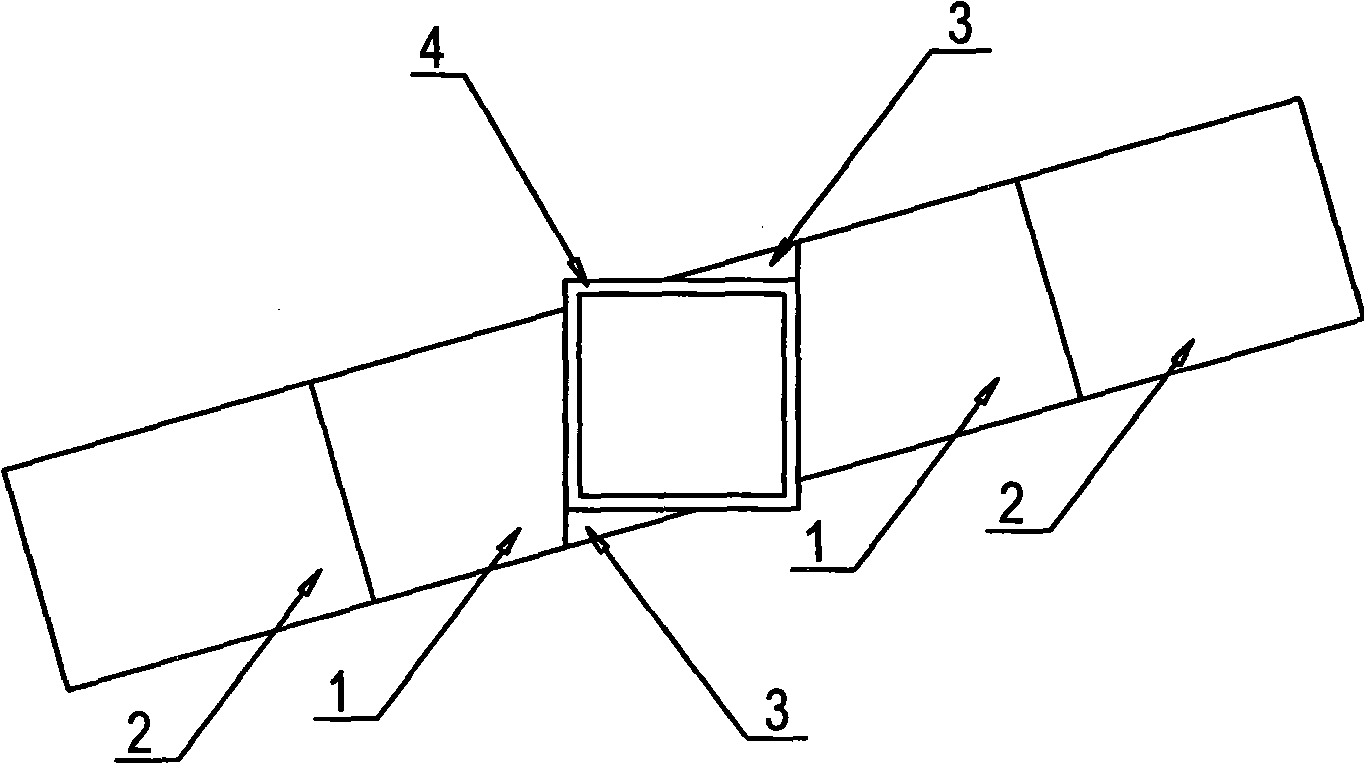

[0036] Such as figure 1 , 2 , 3 and 4, a rectangular cross-section steel member torsionally meets and welds intersecting joints, including a longitudinal joint 1 and two transverse joints 3, the transverse joints 3 are composed of folded plates and flat plates, which can be structurally It is divided into a first block 3-1 and a second block 3-2. The folded plate means that the upper surfaces of the first block 3-1 and the second block 3-2 are formed by a folded plate. The flat plate means that the sides of the first block 3-1 and the second block 3-2 are respectively two flat plates. The plane projections of the first block 3-1 and the second block 3-2 are triangular or quadrilateral, the end face 3-3 of the first block 3-1 is welded in alignment with the side of the longitudinal joint 1, and the second block 3-2 The end face 3-4 of the first block is aligned and welded with the end face of the transverse steel member 4; the two ends of the longitudinal joint 1 are connect...

Embodiment 2

[0043] Rectangular cross-section steel members are twisted, intersected and welded intersecting joints. The transverse steel member 4 is H-shaped steel, and the longitudinal steel member 1 is square steel pipe. The folded plate is the longitudinal joint of the node.

[0044] According to the method of the present invention, a series of embodiments can also be developed. For example, the transverse steel member 4 can adopt rectangular steel pipes, square steel pipes or steel members with other cross-sectional forms according to design requirements. The longitudinal steel member 2 can also adopt rectangular steel pipes, square steel pipes or other cross-sectional steel members according to design requirements. The longitudinal steel member 2 and the transverse steel member 4 do not necessarily have the same width, nor do they necessarily need to have the same section height. The components that meet together do not have to be bidirectional, but can be in multiple directions.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com