Vibration-reducing road pad and method for paving monolithic roadbed track by adopting vibration-reducing road pad

A technology of integral track bed and track pad, which is used in tracks, track laying, track maintenance, etc., can solve problems such as rail vibration, and achieve the effect of reducing resistance and wear and effectively isolating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

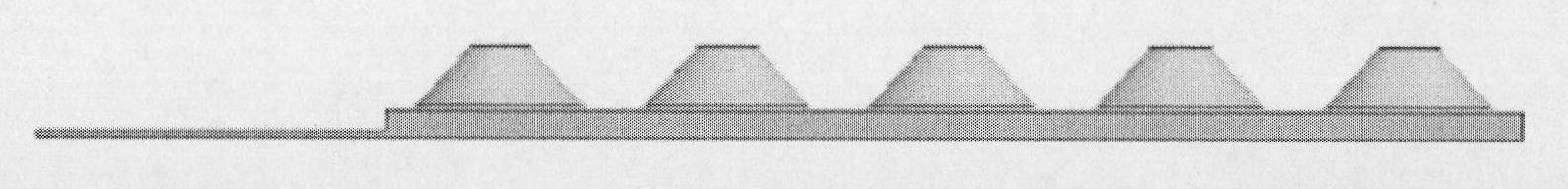

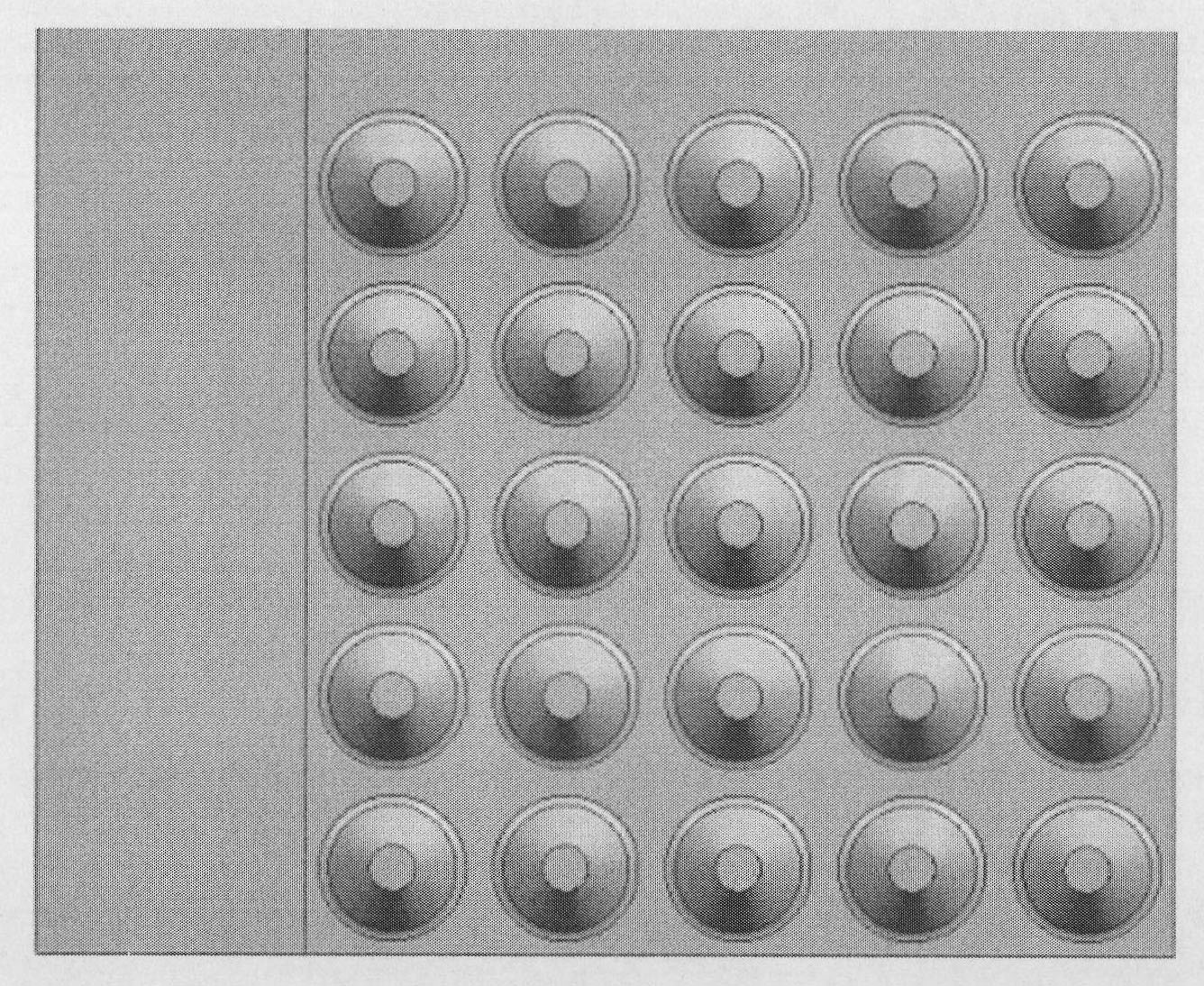

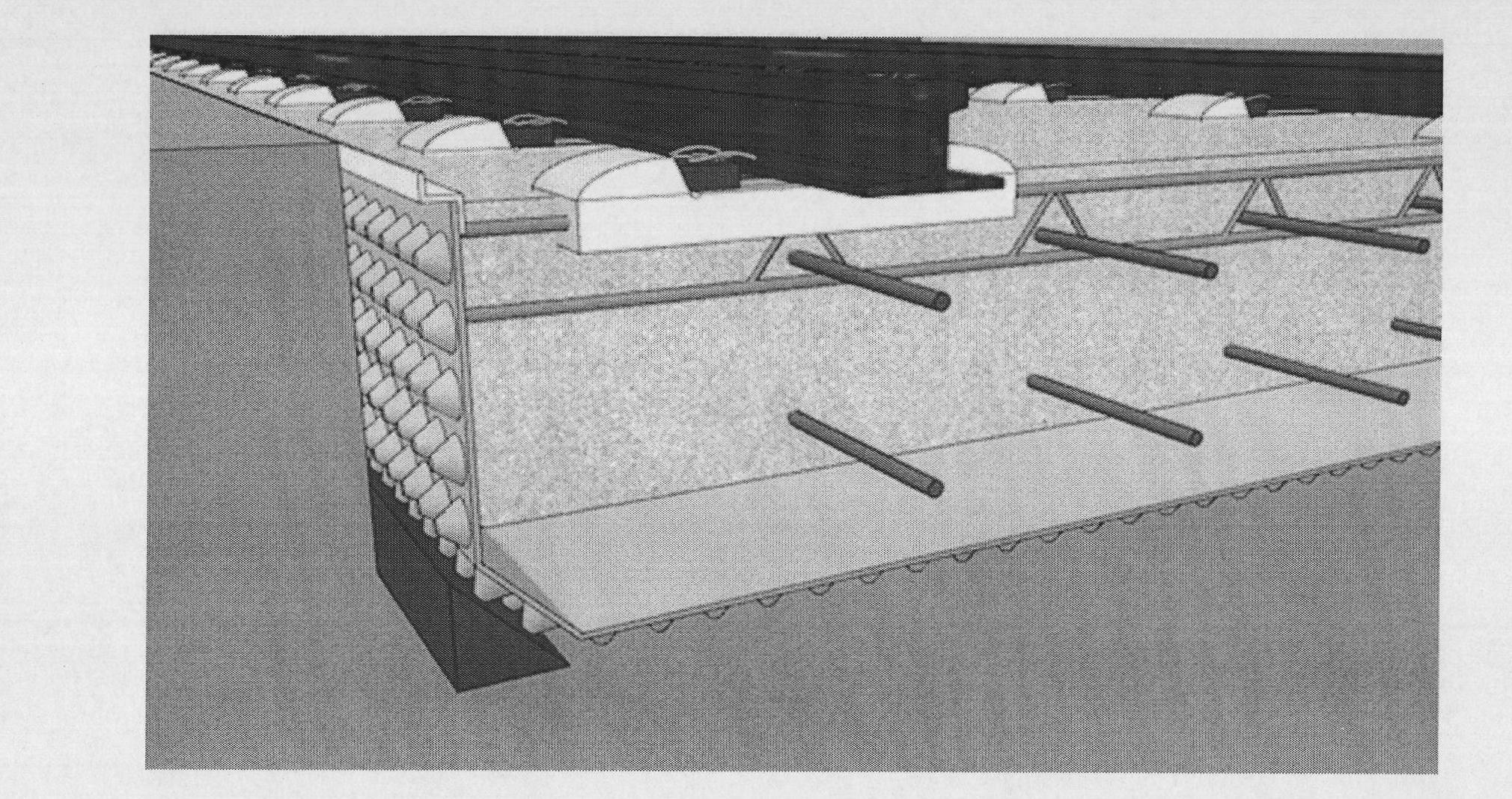

[0034] see figure 1 , figure 2 Shown, damping track pad of the present invention is formed by the conical protrusion on the base and the base, by being installed under the rail (see image 3 ), the pad can effectively reduce vibration and noise, with Figure 4 Shows the specific composition of the substrate, which consists of a damping layer 10, a rubber coating 9, a woven fabric layer 8, a rubber coating 7, an interlayer 6, a rubber coating 5, a woven fabric layer 4, a rubber coating 3 and a cover layer in sequence 2. There is an overlapping strip 1 in the covering layer, which can be used to connect and manufacture longer width and length damping track pads, for example, through two vibration damping track pads with a width of 1 meter. lap strips, so that a 2-meter-wide damping track pad can be formed; at the same time, multiple conical protrusions are formed on the damping layer 10 of the base, and the effect of bearing pressure is better by using the special-shaped sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com