High-temperature resistance base fluid for well cementing of oil gas well, preparation method and application thereof

A technology for high temperature resistance and well cementing, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to aggravate, performance index decline, inability to ensure effective isolation of drilling fluid and cement slurry, etc., to achieve compatibility Good performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Below in conjunction with embodiment, further illustrate the present invention.

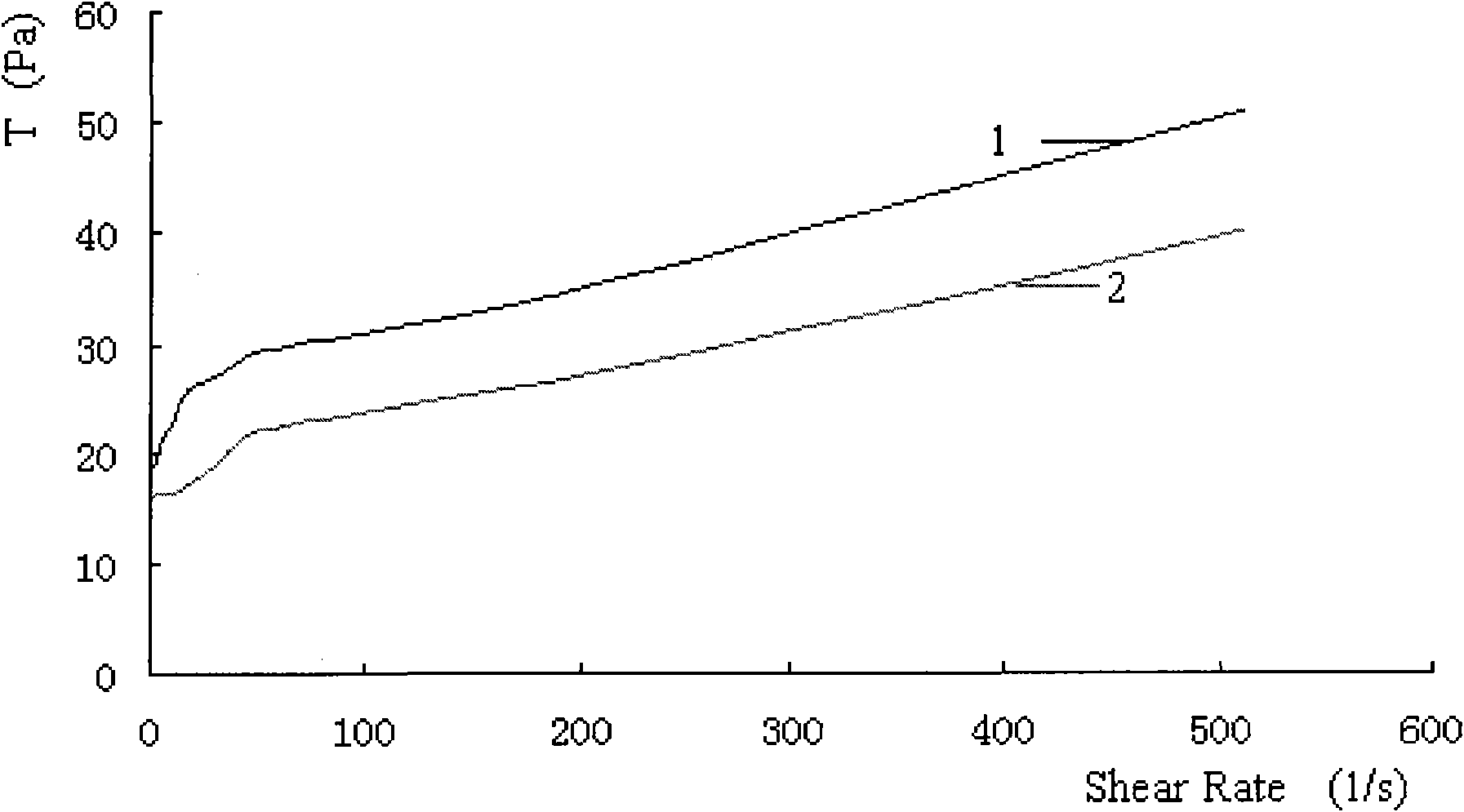

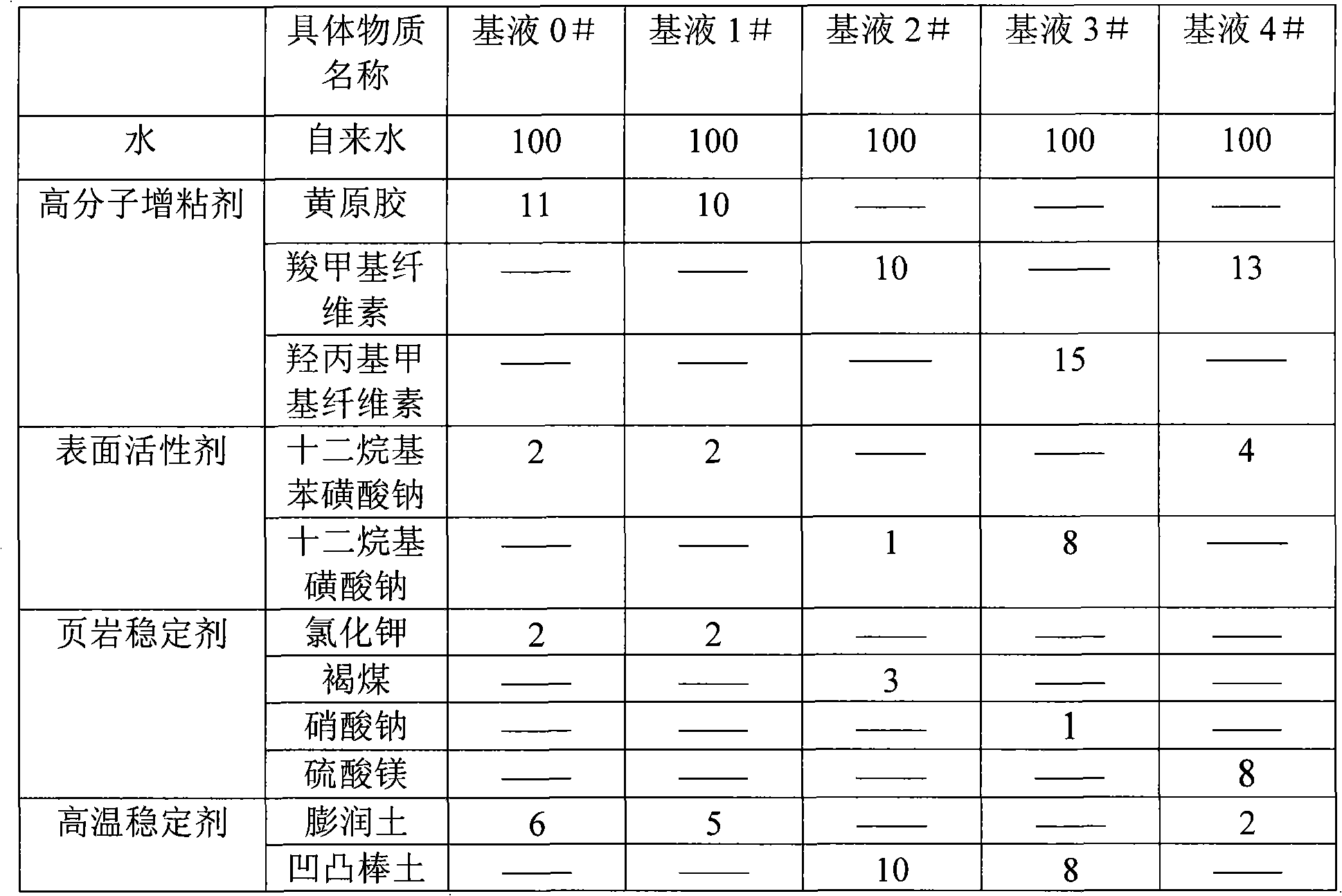

[0031]Most of the wells using weighted spacer fluid are faced with short and long sealing sections, large temperature difference between upper and lower, salt layer or salt gypsum layer, etc., and the well conditions are complex. For example, Well Sha 105 and Well T914 in Tahe Oilfield all contain salt-gypsum layers, and the drilling fluid is an undersaturated salt-calcium-based drilling fluid, and the performance density of the drilling fluid is 1.68g / cm when drilling is completed. 3 Above, the rheology is not good, the design viscous spacer fluid density is 1.78g / cm 3 . The base fluid of the present invention is aggravated with iron ore powder, and the slurry preparation water is semi-saturated brine or on-site water, which is prepared in a storage tank 2 days in advance, and there is no settlement phenomenon during cementing, indicating that the suspension performance is good. Its spe...

Embodiment 2

[0039] Compatibility test of drilling fluid and cement slurry:

[0040] Adopt a good cement slurry formula of performance index and on-the-spot drilling fluid formula, spacer fluid 4# (density is 1.60g / cm3) prepared by base fluid 4# of the present invention 3 ) with cement slurry and drilling fluid according to 16.3 of the oil well cement test method (GBT / 19139-2003) in different volume ratios, after stirring fully, cured at 95°C for a period of time, and evaluated the spacer fluid and cement slurry and on-site drilling Liquid compatibility. The experimental results are shown in Table 3. Experiments have proved that the spacer fluid prepared from the high-temperature resistant oil and gas well cementing base fluid of the present invention has very good compatibility with cement slurry and drilling fluid, and any contact between the two will not produce special thickening or flocculation, which is beneficial Improve displacement efficiency and improve cement sheath cementatio...

Embodiment 3

[0056] The horizontal section of Tahe Oilfield is drilled with mud mixed with 8-10%wt crude oil. The mud cake formed in this way contains crude oil. If no measures are taken to remove the oil film on the casing and well wall of the wells drilled with oil-based mud, even if the solid During the well construction, the displacement efficiency reaches 100%, and the well logging curve shows very poorly. Therefore, the existence of the oil film affects the bonding quality of the cement stone, the casing and the well wall. The flushing fluid prepared by using the base fluid for high-temperature resistant oil and gas well cementing of the present invention can flush, dilute, and isolate mud, easily form turbulent flow, and effectively clean the oil film adhered to the well wall and casing wall. The displacement efficiency of the cement slurry is improved, and the surface environment of the casing and the borehole wall is more suitable for bonding with cement, which is conducive to impr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com