Rotating die cutting device

A technology of rotating die and slider, applied in the field of machinery, can solve the problems of inconvenient adjustment, damaged bearing position, affecting the accuracy of loading and unloading knife rollers, etc., and achieve the effect of convenient adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

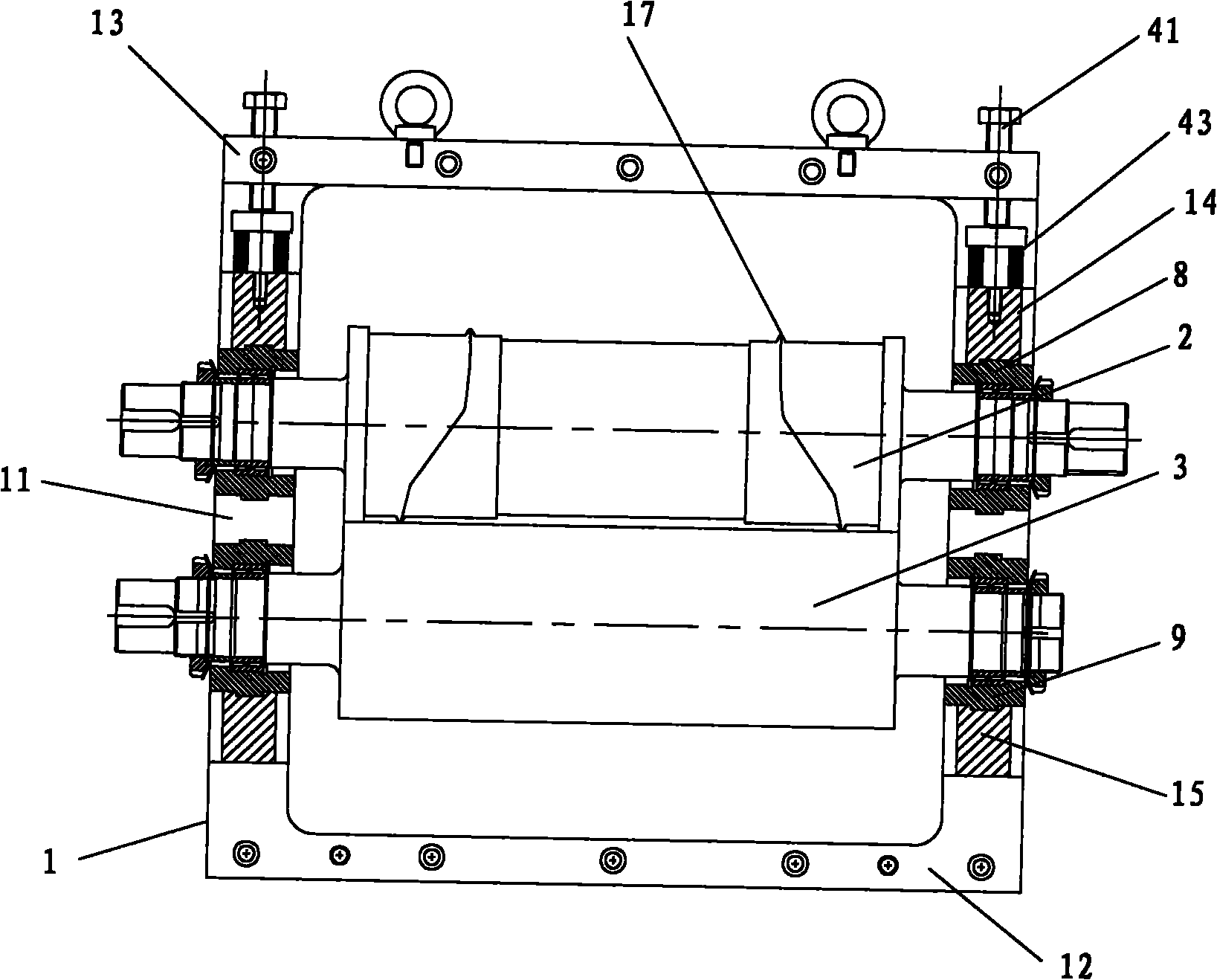

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

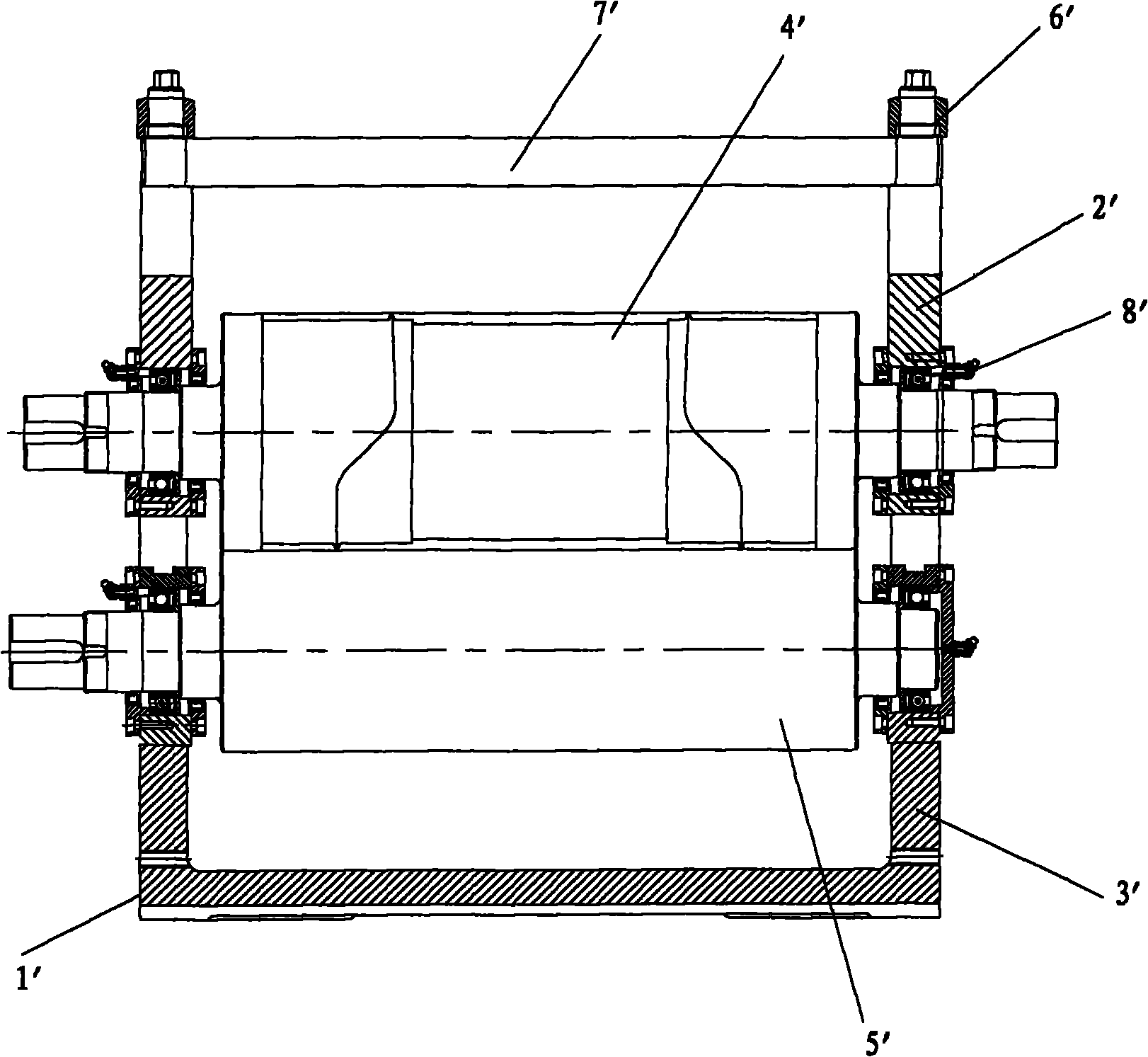

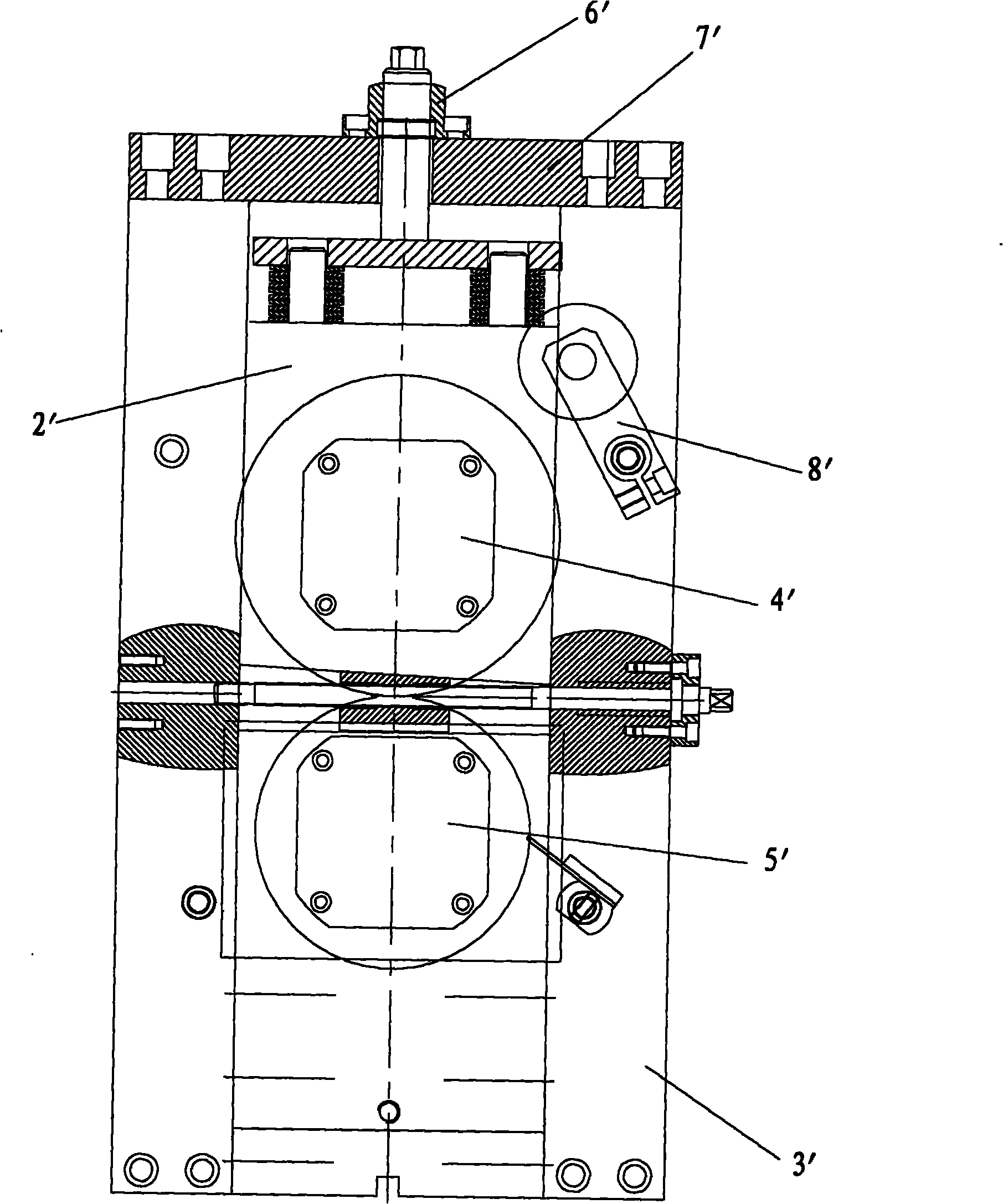

[0033] Please refer to Figure 3 to Figure 8 As shown, the present invention discloses a rotary die-cutting device, which includes a frame body 1, an upper knife roller 2 and a lower knife roller 3 fixed on the frame body 1, and two ends respectively installed on the upper knife roller 2 and the lower knife roller 3. The upper bearing sleeve 8 and the lower bearing sleeve 9 and the upper slider 14 and the lower slider 15 connected with the upper bearing sleeve 8 and the lower bearing sleeve 9 respectively, wherein: including a pressurization mechanism 4 and a pressure relief mechanism 5, the pressurization The mechanism 4 cooperates with the upper bearing sleeve 8 through the upper slider 14, and the pressing mechanism 4 exerts a downward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com