Chip module structure assembly

A chip module and assembly technology, applied in the field of chip module structure assembly, can solve problems such as easy heat storage, difficult heat dissipation, and inability to load heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

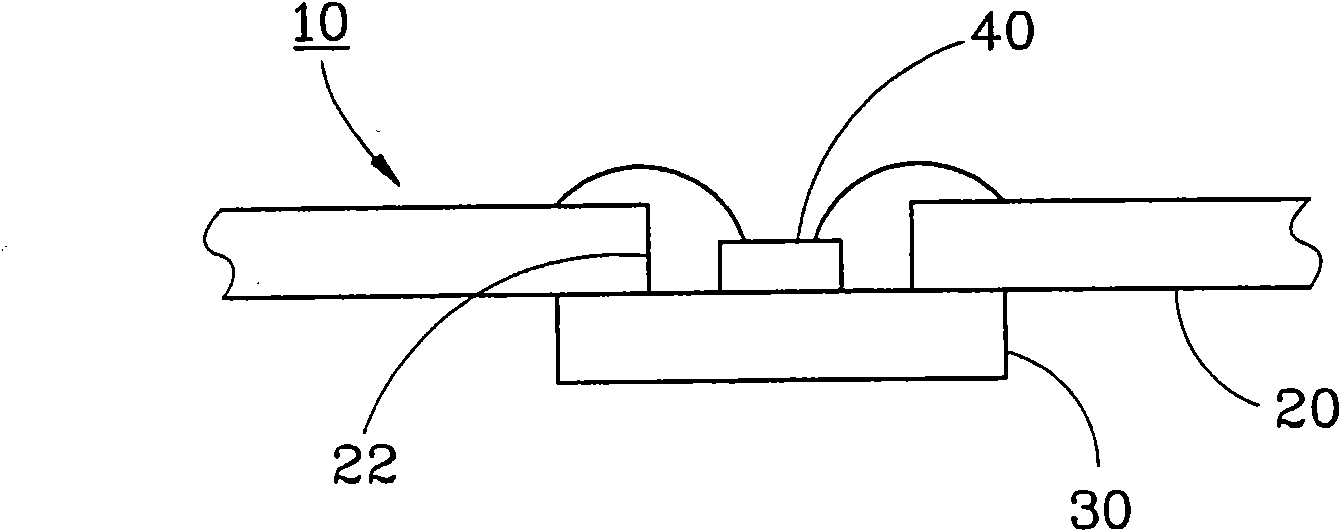

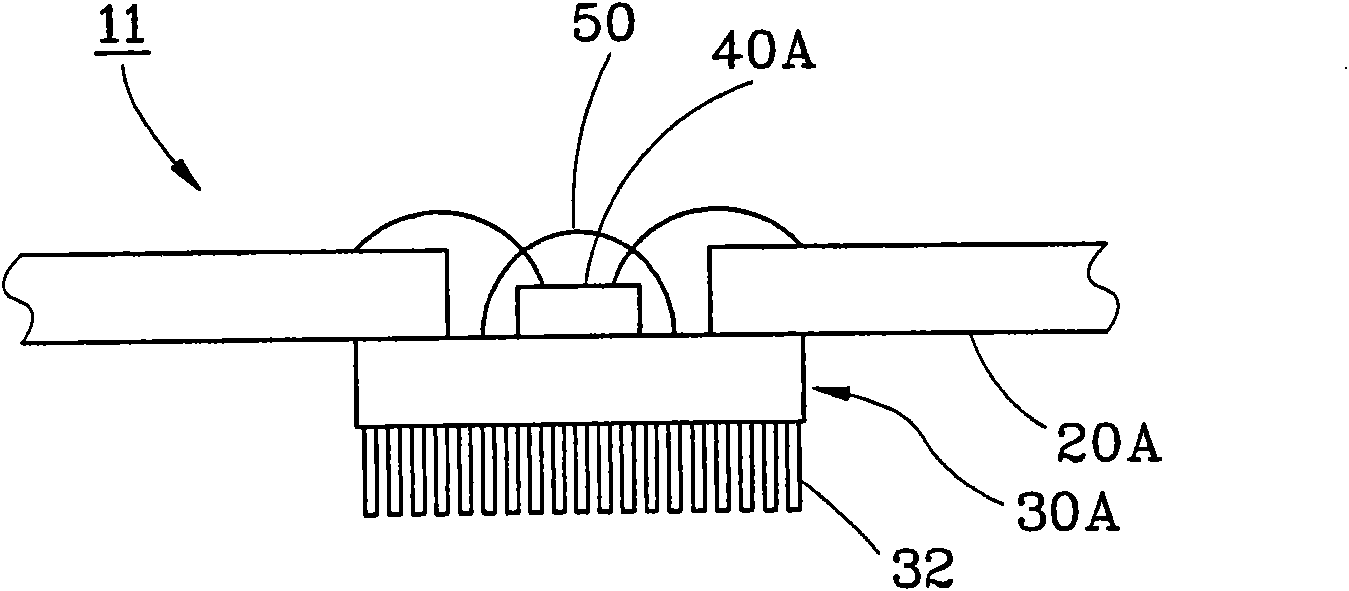

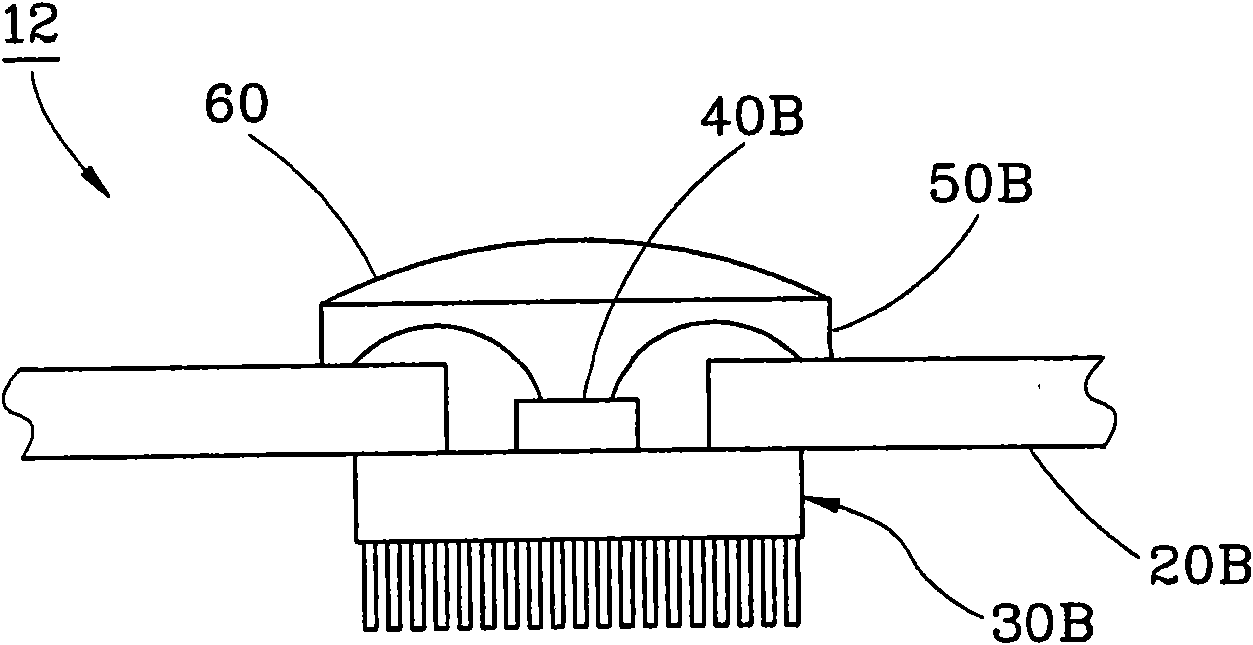

[0069] see figure 1 , The chip module structure assembly 10 provided by the first preferred embodiment of the present invention includes: a substrate 20 , a heat dissipation plate 30 , a chip 40 and a light-transmitting layer 50 .

[0070] The substrate 20 is flat and has a through hole 22; in this embodiment, the number of the through holes 22 corresponds to the number of the chips 40, and the number of the through holes 22 is taken as an example, which is only for illustration and not as a limiting requirement. .

[0071] The heat dissipation plate 30 is arranged on the bottom surface of the base plate 20, generally in the shape of a flat plate, and its position corresponds to the through hole 22; the thermal conductivity of the heat dissipation plate 30 is higher than that of the base plate 20; in this embodiment, the heat dissipation plate 30 is made of metal The material is only used as an example, not as a limiting requirement.

[0072] The chip 40 is disposed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com