Vacuum assisted brake system, control method thereof, and vehicle comprising vacuum assisted brake system

A technology of vacuum boosting and control methods, which is applied to vehicle parts, transportation and packaging, and braking safety systems, etc., can solve the problems of potential safety hazards and inability to provide vacuum boosting stably, and achieve prolonging service life, reducing working hours and The effect of starting and stopping times and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings.

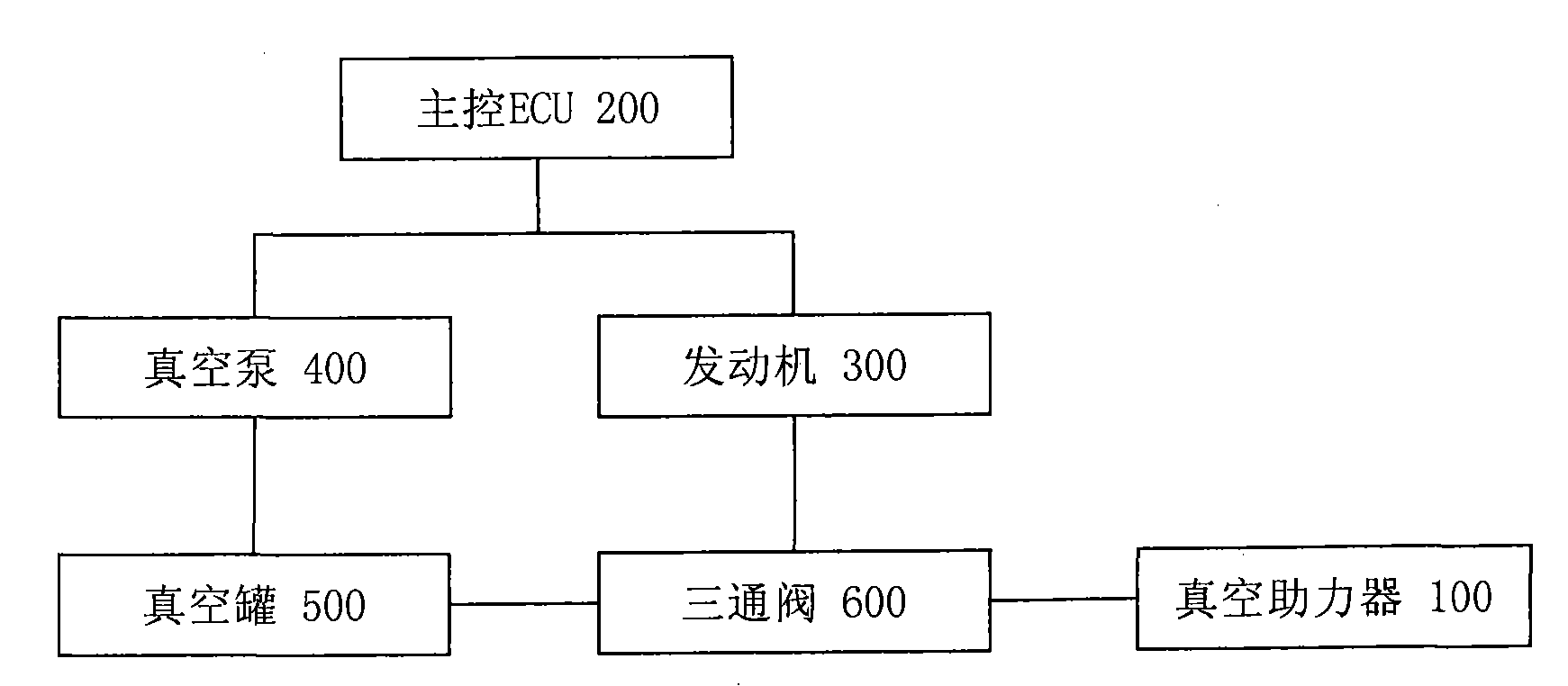

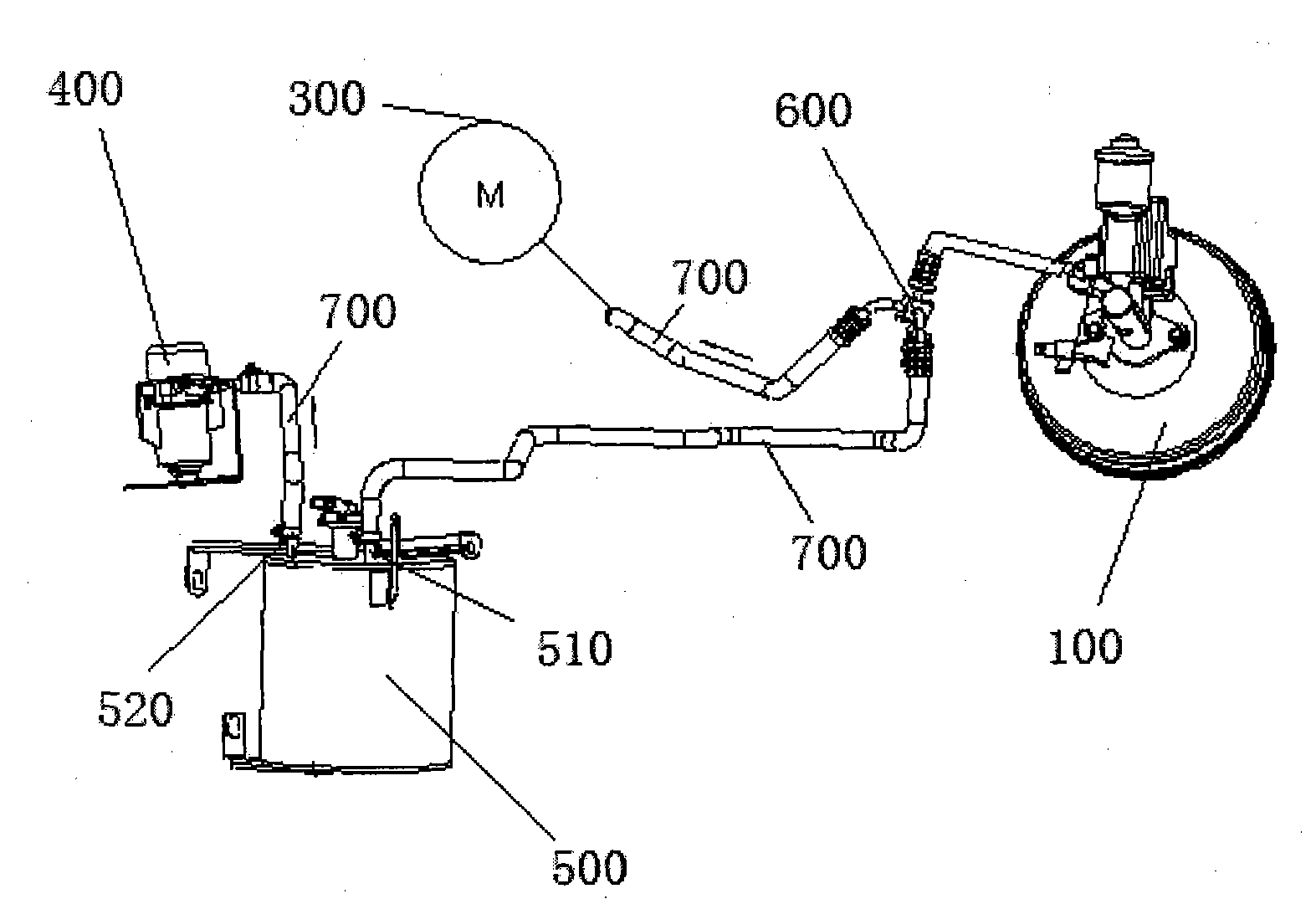

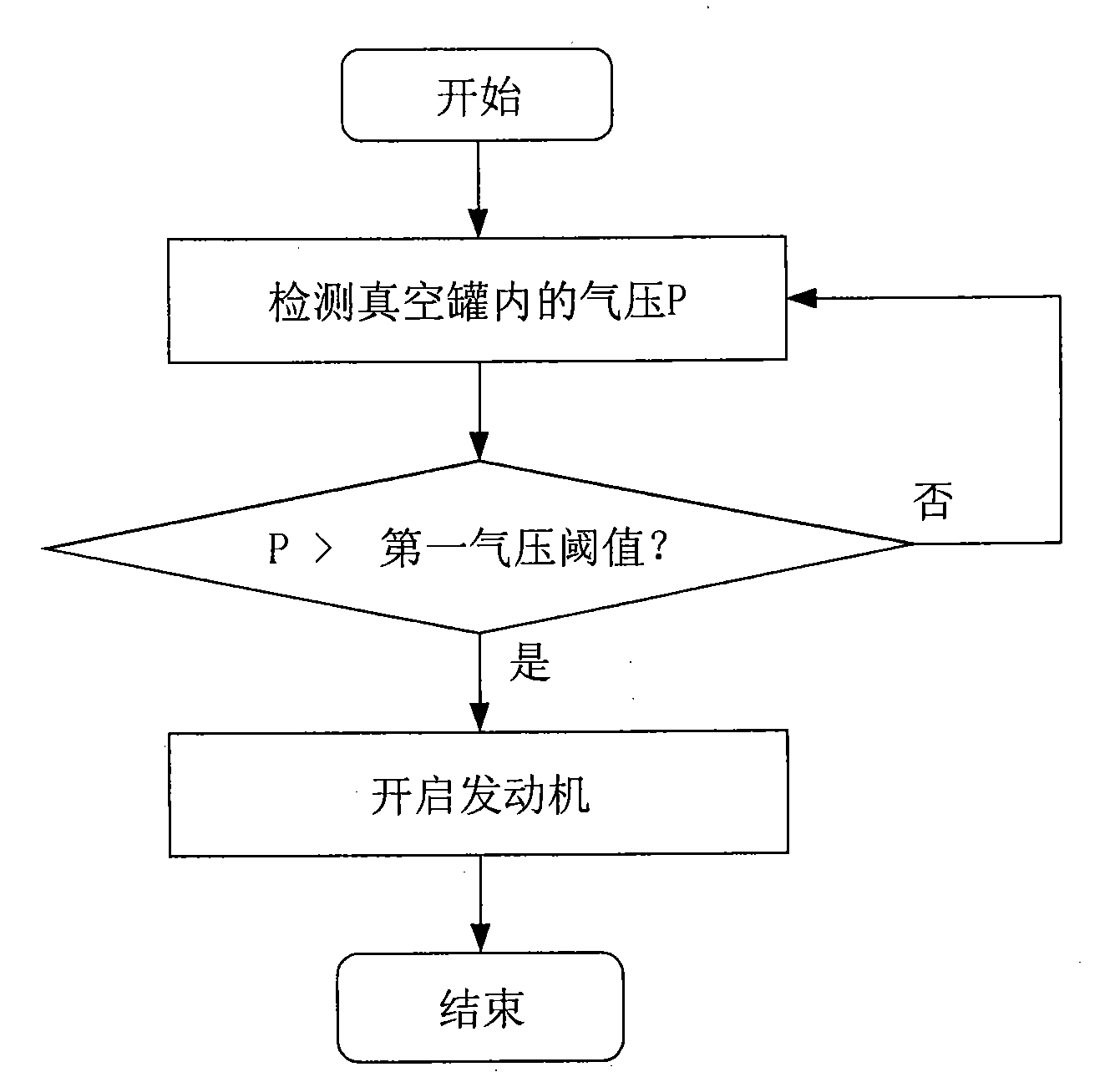

[0017] Such as figure 1 As described above, the present invention provides a brake vacuum booster system, which includes a vacuum booster 100, a vacuum pump 400, a vacuum tank 500, and a main control ECU 200. The vacuum pump 400 passes through the vacuum tank 500 and the vacuum booster 100. The servo air chamber is connected, and the main control ECU200 is electrically connected with the vacuum pump 400, wherein the brake vacuum booster system also includes an engine 300, and the intake manifold of the engine 300 communicates with the vacuum servo air chamber of the vacuum booster 100, The main control ECU 200 provides a vacuum environment for the vacuum booster 100 by controlling the engine 300 and the vacuum pump 400 to be turned on and off so that the engine 300 serves as a main vacuum source and the vacuum pump 400 serves as an auxiliary vacuum source.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com