Component for preventing the losing of cover

A technology for components and parts, which is applied in the field of preventing the loss of cover components, can solve the problems of increased manufacturing cost, failure, and limited use of the connecting component 11, and achieves the effect of expanding the use and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

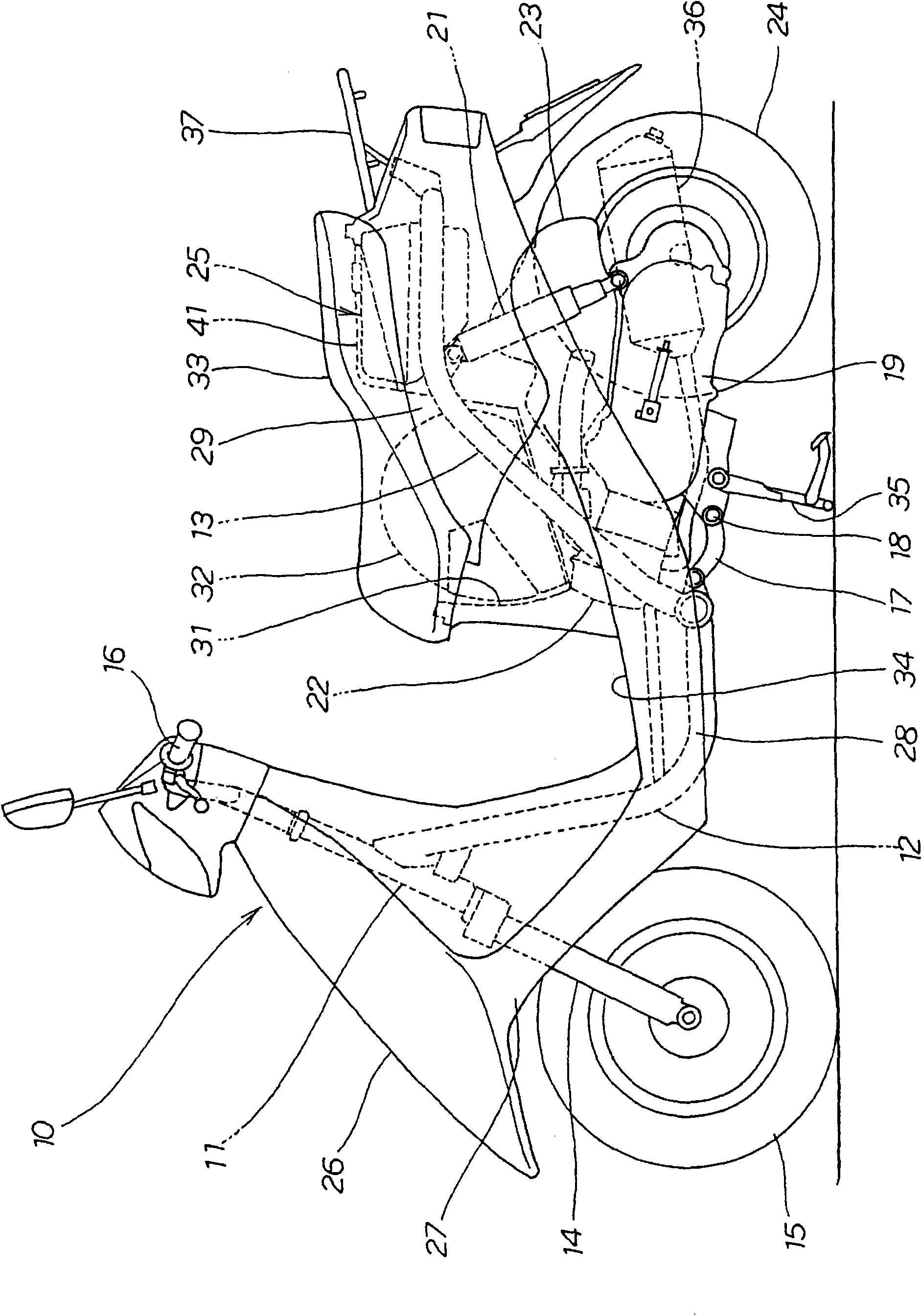

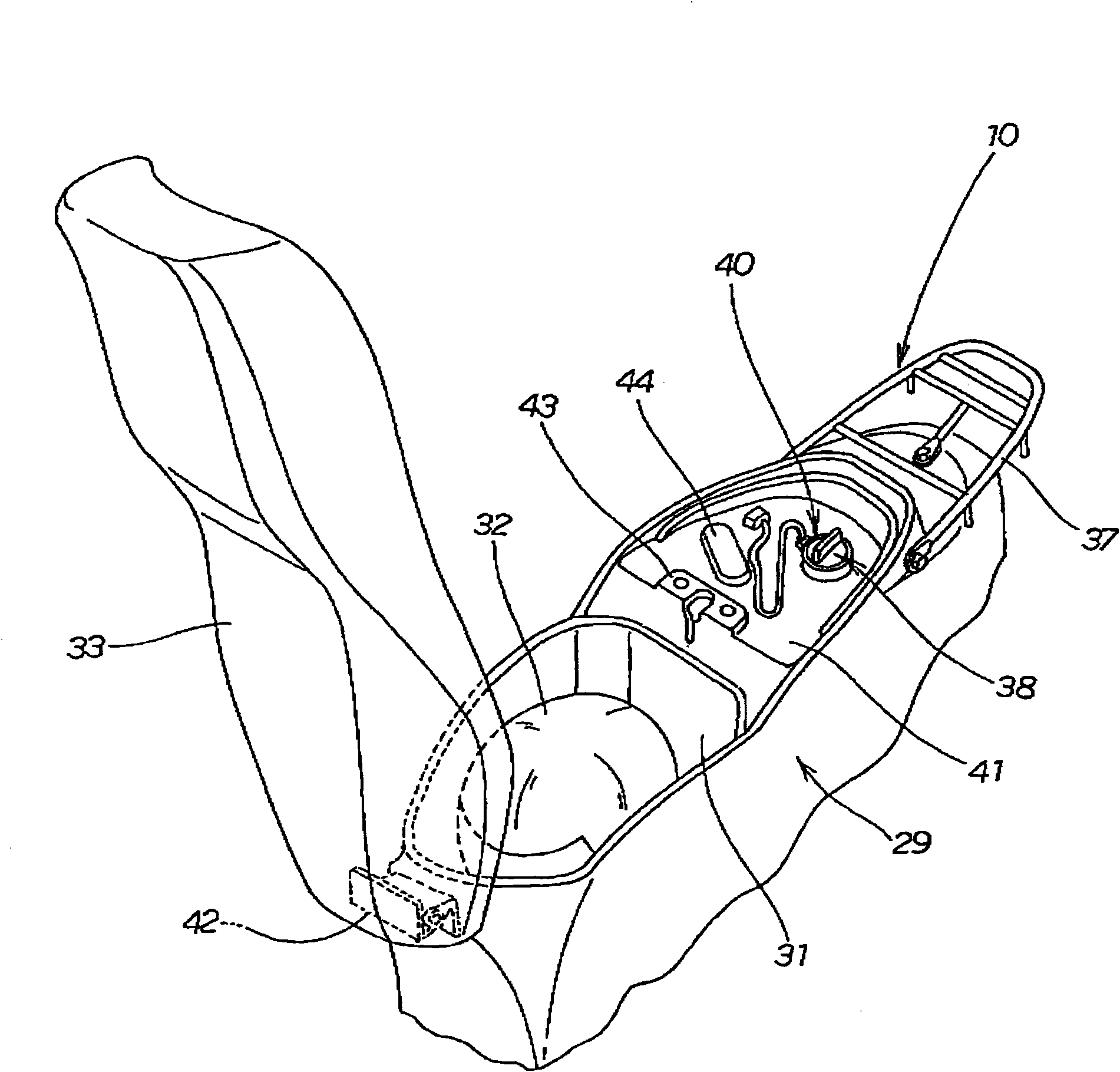

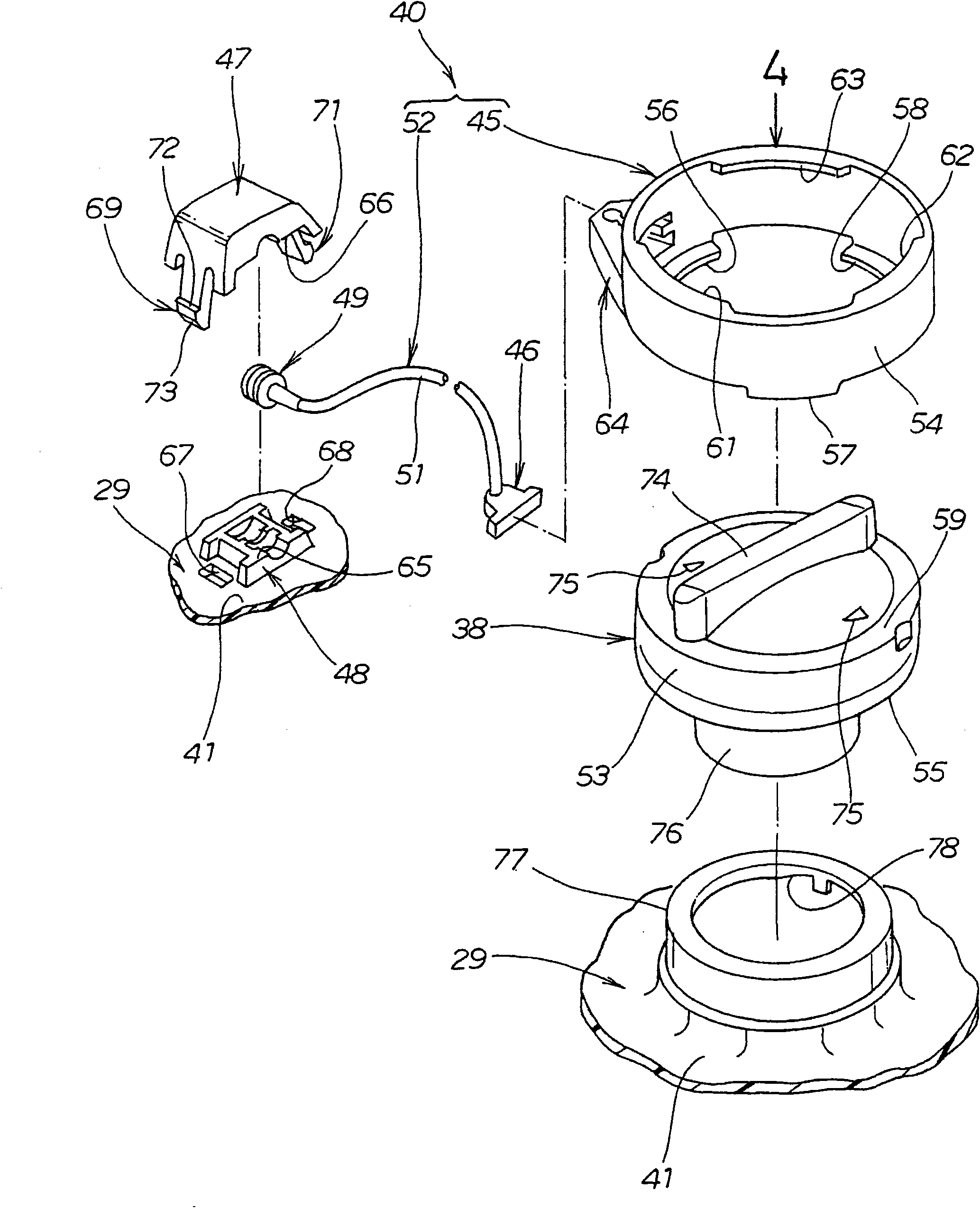

[0041] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings. In addition, the drawings are views seen from the direction of the reference numerals. Hereinafter, the container will be described as a fuel tank of a motorcycle, and the cap will be described as a fuel tank cap.

[0042] figure 1 It is a side view of the motorcycle according to the present invention. Hereinafter, the traveling direction of the vehicle is referred to as the front, and the vehicle width direction is referred to as the left and right sides.

[0043] The motorcycle 10 has a main frame 12 extending downward and rearward from a head pipe 11, and a rear frame 13 extending rearward and upward from the main frame 12 to form a vehicle body, and a front fork 14 is rotatably attached to the head pipe 11. , the front wheel 15 is installed on the front fork 14, the handle 16 is installed at the upper end of the front fork 14, the connecting part 17 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com