Extrusion forming machine for wood-plastic composite material

A wood-plastic composite material, extrusion molding machine technology, applied in mechanical equipment, gear transmission, belts/chains/gears, etc., to prevent material leakage and blockage, improve effective extrusion, and save floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

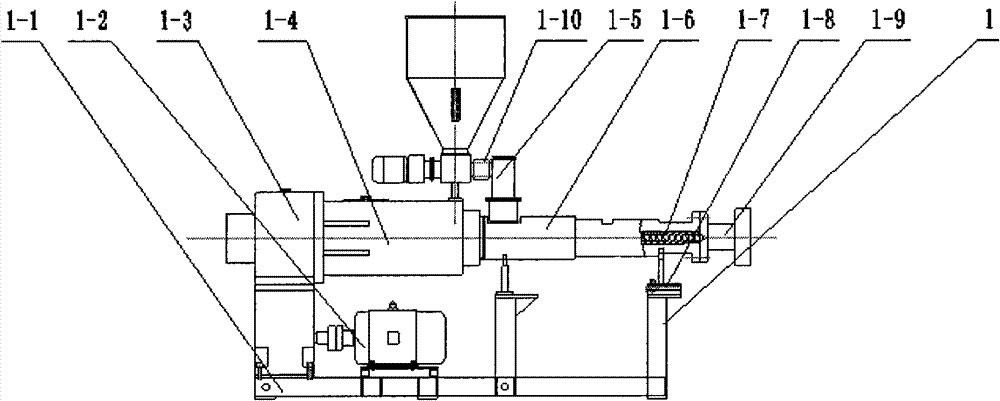

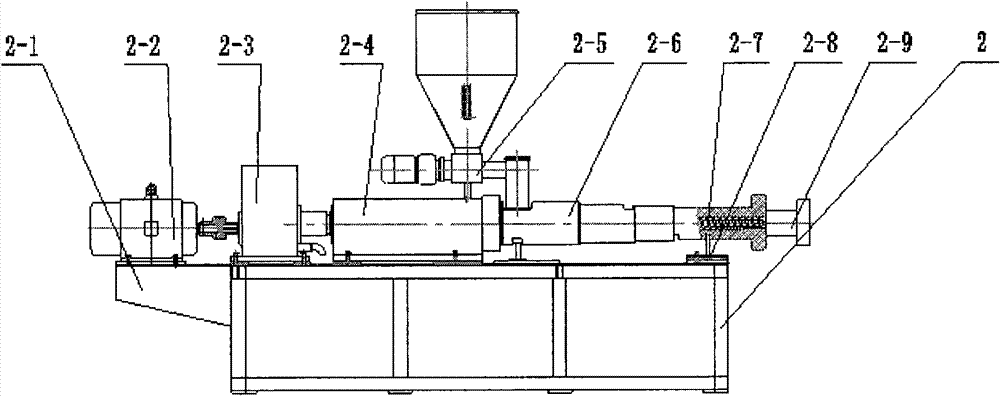

[0061] figure 1 It is a schematic diagram of a twin-screw extruder of the present invention, including a motor 1-2, a reduction gear box 1-3, a distribution gear box 1-4, a feeding device 1-5, a barrel 1-6, an extrusion screw 1-7, a confluence Cores 1-9, preheaters 1-10. The motor 1-2 is installed on the inside of the reduction gearbox 1-3 and the distribution gearbox 1-4, and the motor 1-2 drives the extruding screw 1-7 through the reduction gearbox 1-3 and the distribution box 1-4; the feeding device The outlet of 1-5 is connected to the feed port of barrel 1-6, and feeds to barrel 1-6. Extrusion screw 1-7 is installed in barrel 1-6, and squeezed by extrusion screw 1-7 , the material is sent out from the confluence core 1-9. figure 2 It is a schematic diagram of an existing twin-screw extruder. figure 2 The motor 2-2, reduction box 2-3, distribution box 2-4, feeding device 2-5, barrel 2-6, extruding screw 2-7 confluence core 2-9 are connected in series; the motor 2- 2 D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com