High-efficiency and energy-saving magnet pot

A high-efficiency, energy-saving, magnet technology, applied in the field of magnet pots, can solve the problems of large fumes, fuel consumption, electricity consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

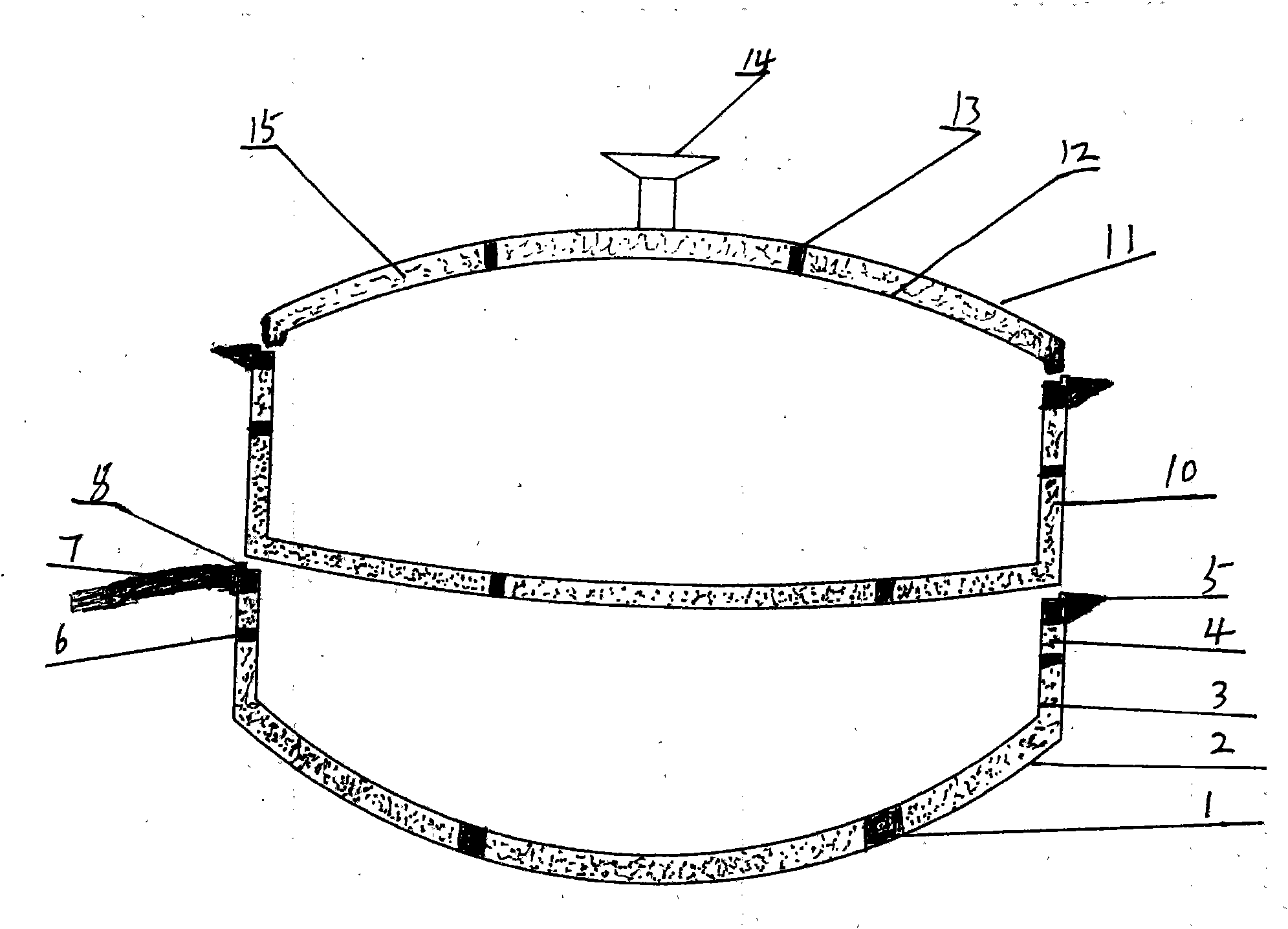

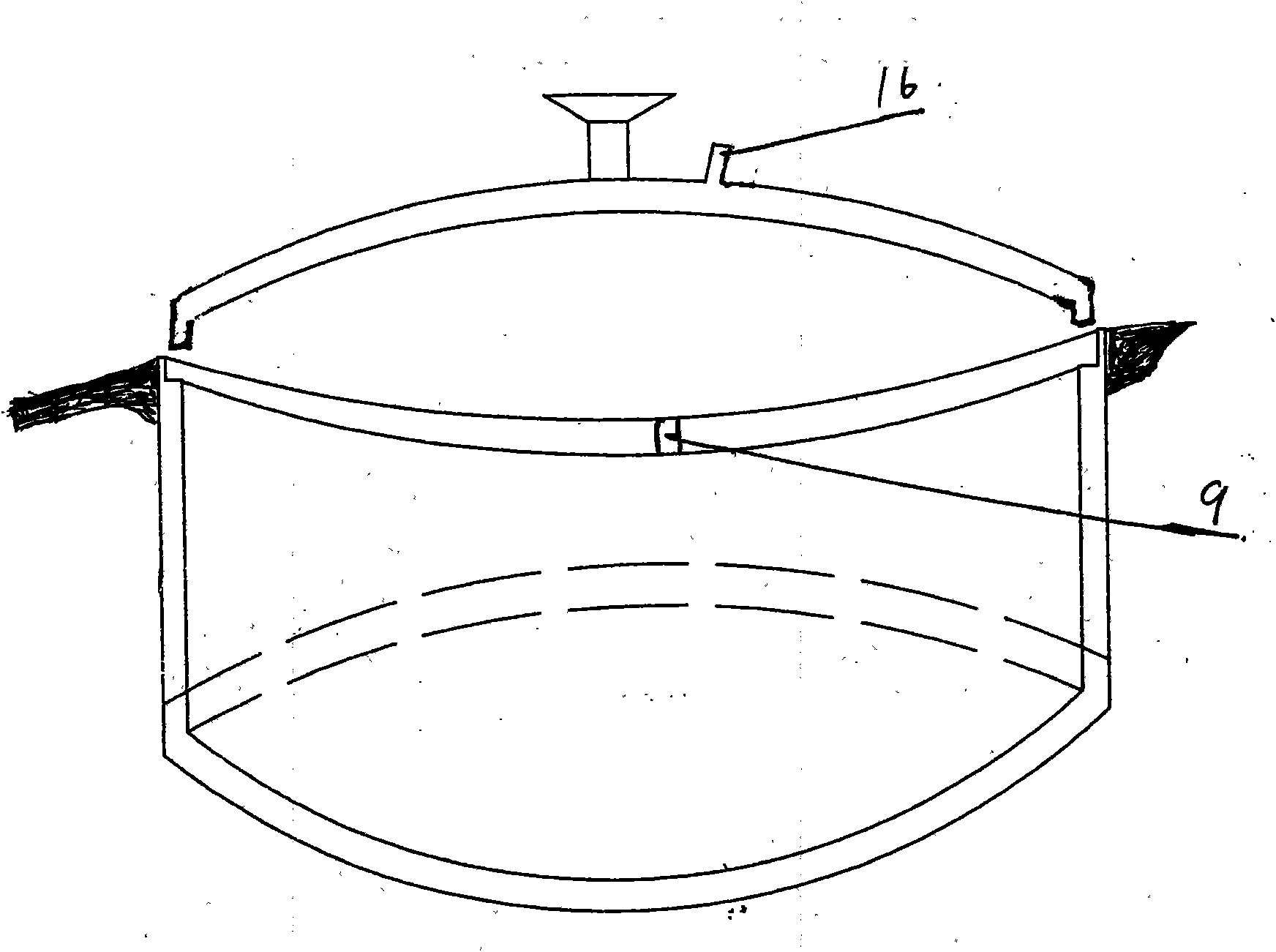

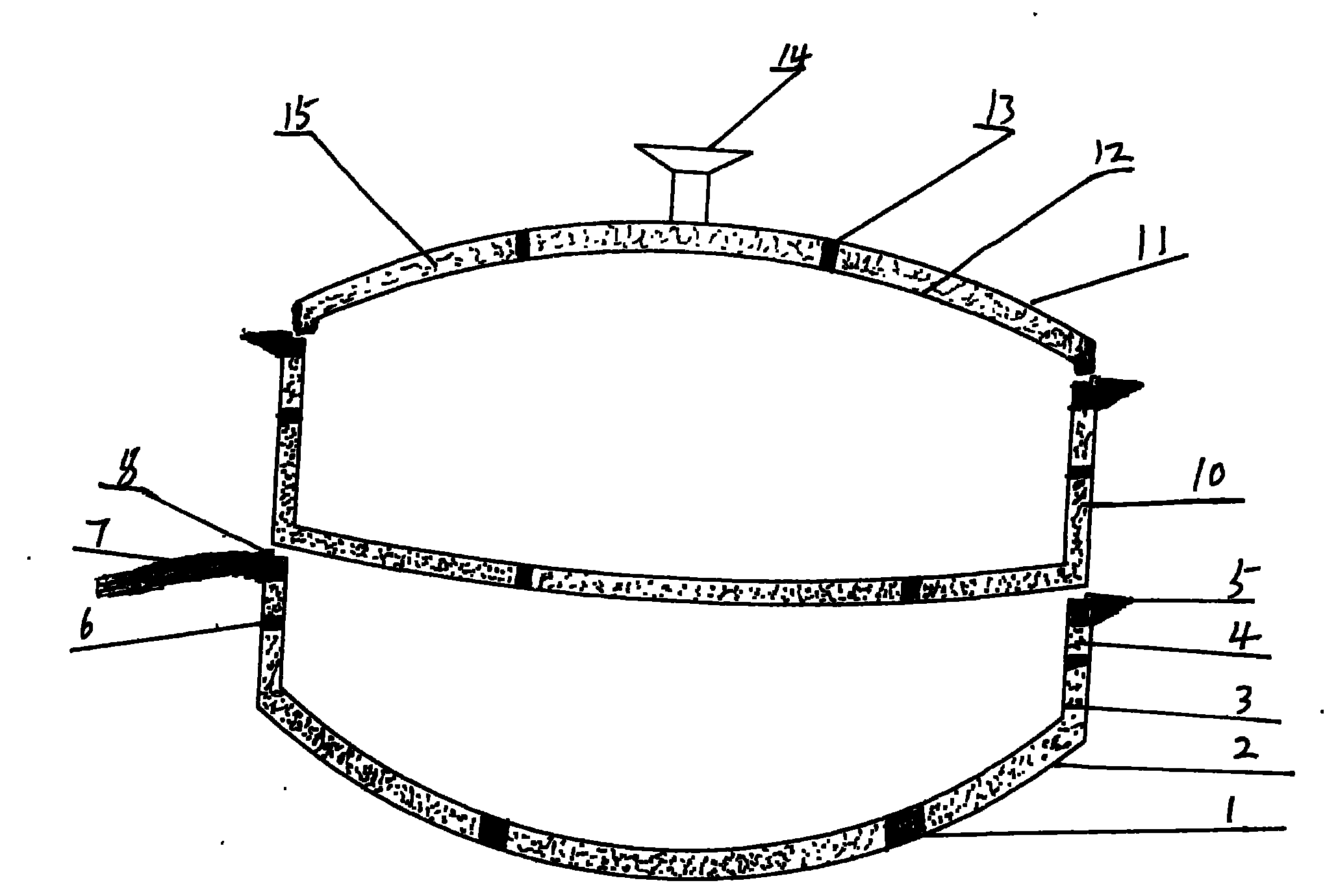

[0015] A high-efficiency and energy-saving magnet pot is composed of an outer pot (2), the difference is that the inner end of the outer pot (2) is connected to the bottom magnetic iron (1) and the magnet (6) at the middle end of the pot is connected to a high temperature Oil (3), connected to the inner end (4), connected to the side of the pot (8), the outer end of the outer layer pot (2) connected to the pot oil hole and cover (9), connected to the right handle (5) connected to the left handle (7) The upper end that has multilayer pot (10) connects pot cover outer layer (11) connects pot cover magnet (13) connects pot cover high-temperature oil (15) connects pot cover inner layer (12), and outer end connects pot cover handle (14 ) to connect the pot cover oil hole and the cover (16).

[0016] When in use, first add raw ingredients, and then start to burn. The high-efficiency and energy-saving magnet cooker produces authentic ingredients.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com