Flexible sealing and water sealing rotary forced-air cooler

A cooling machine, blast ring technology, applied in the direction of engine sealing, furnace cooling, mechanical equipment, etc., can solve the problems of large weight increase, difficult processing, rapid damage to rubber sheets, etc., to prevent air and surrounding environment pollution, improve The effect of blowing efficiency and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

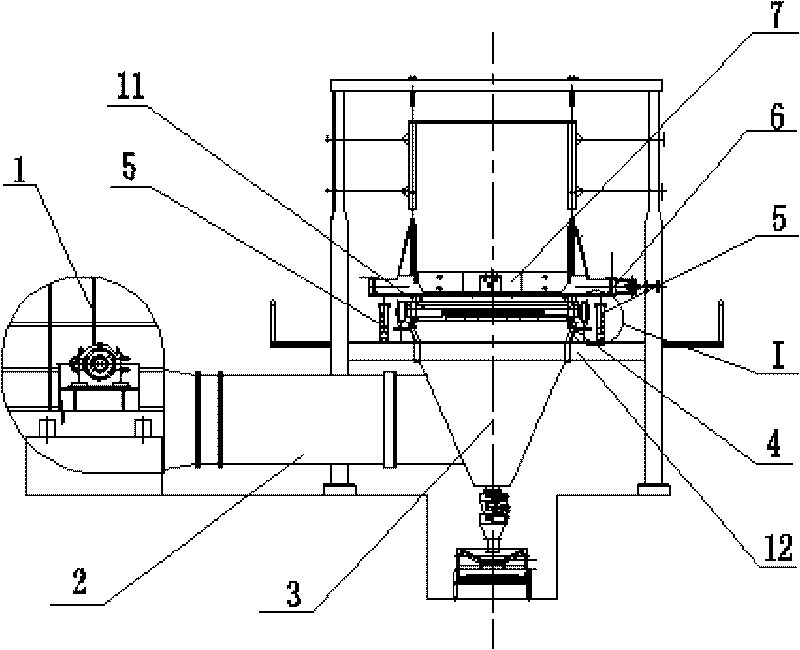

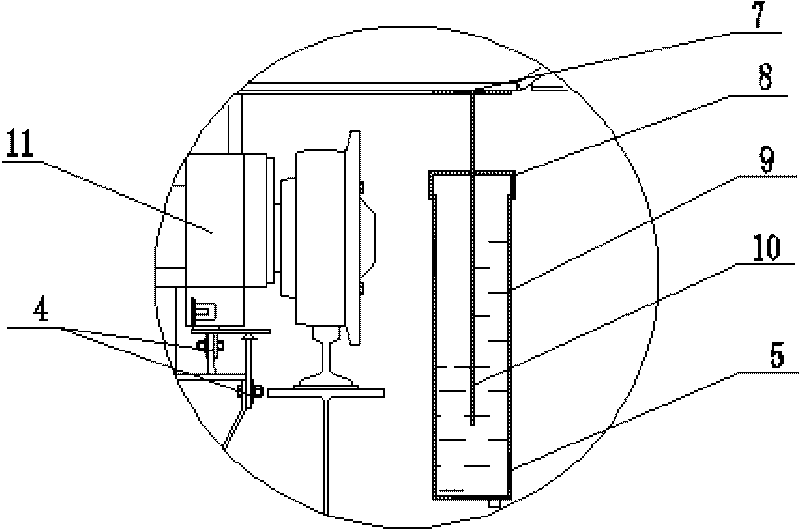

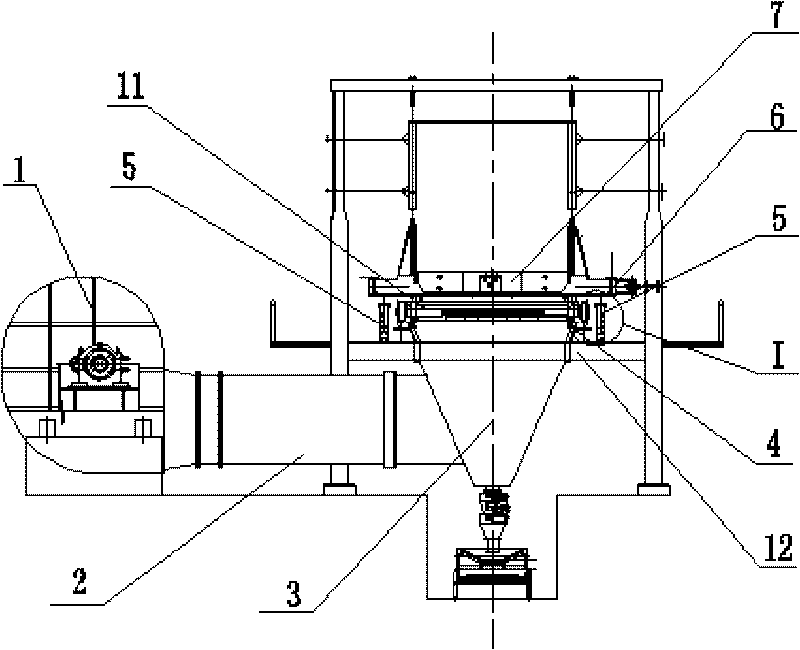

[0023] by attached figure 1 , figure 2 As shown, a blower ring cooler with flexible seal and water seal includes several blowers 1 connected to the bellows 3 through the air pipe 2, the outer circumference of the top of the bellows 3 is connected to one side of the flexible seal 4, and the flexible seal The other side of 4 is connected with the rotating beam 11 of the trolley 7, and the water sealing device 5 is arranged outside the flexible sealing device 4 and the rotating beam 11, and the rotary sealing device 6 and the water sealing device 5 are movably connected on the outer circumference of the trolley 7. Including the top of the annular water tank 9 connected to the cover plate 8, the center of the annular water tank 9 is provided with an annular partition 10, and the annular partition 10 is fixed on the bottom of the trolley 7; Stretch into the bottom of the annular water tank 9 through the annular groove; seal water is housed in the annular water tank 9; the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com