Roof waterproof structure and manufacture method thereof

A technology of waterproof structure and manufacturing method, which is applied in the direction of roofing, building structure, roof covering, etc., can solve the problems of soaking and heat preservation of the insulation layer, difficulty in finding leaks, failure, etc., to reduce the structure level, improve reliability, The effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further set forth the utility model:

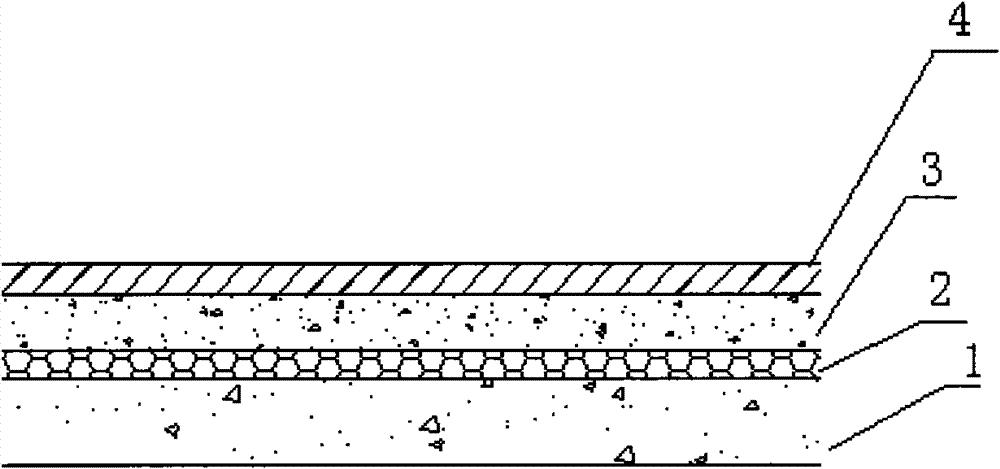

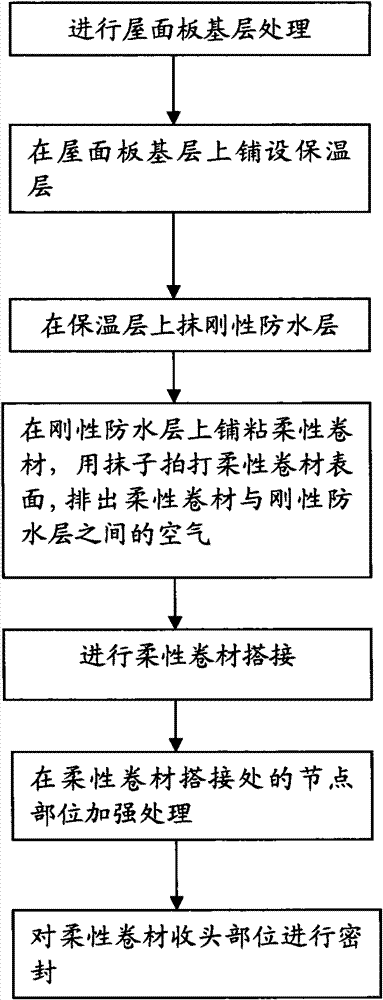

[0029] Such as figure 1 As shown, a roof waterproof structure includes a roof panel base layer 1, an insulation layer 2, a rigid waterproof layer 3 with a protective layer and an adhesive layer, and a flexible coil waterproof layer 4. The insulation layer 2 is laid on the roof panel On the base layer 1, on the insulation layer 2, there are a rigid waterproof layer 3 and a flexible membrane waterproof layer 4 in sequence. The rigid waterproof layer 3 and the flexible membrane waterproof layer 4 are laid synchronously. The rigid waterproof layer 3 in this embodiment is dedicated to wet laying. The waterproof mortar layer prepared by dry powder mortar has the function of the protective layer of the insulation layer 2 and the adhesive layer of the flexible membrane waterproof layer 4; the flexible membrane waterproof layer 4 is an elastomer modified bitumen waterproof membrane that can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com