Stratigraphic liquid nitrogen freezer

A freezer and liquid nitrogen technology, applied in the field of freezers, can solve the problems of uneven distribution of liquid supply, prolonged freezing time, and uneven freezing, so as to achieve uniform development speed of frozen soil, reduce nitrogen consumption, and shorten freezing The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

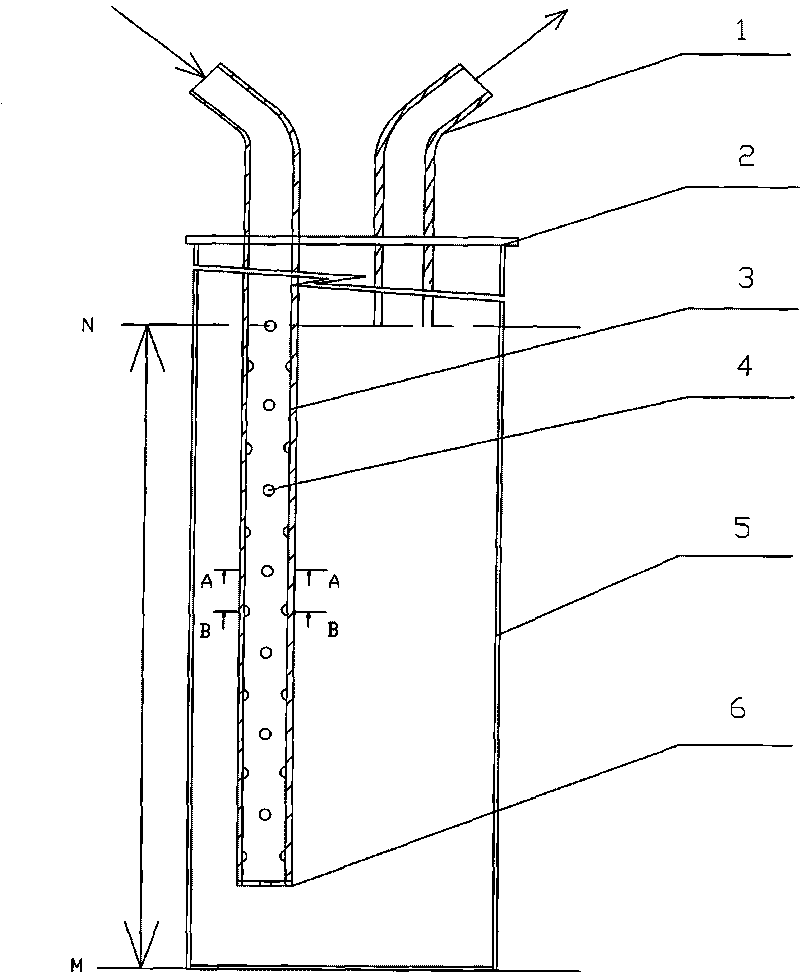

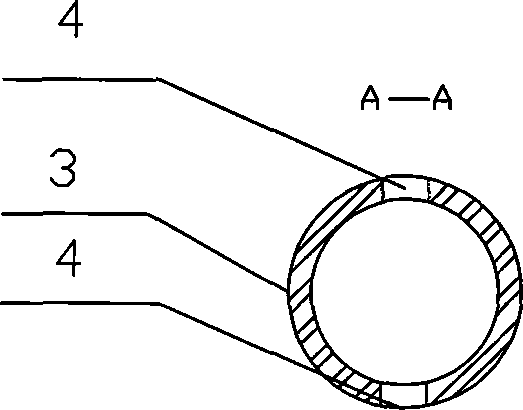

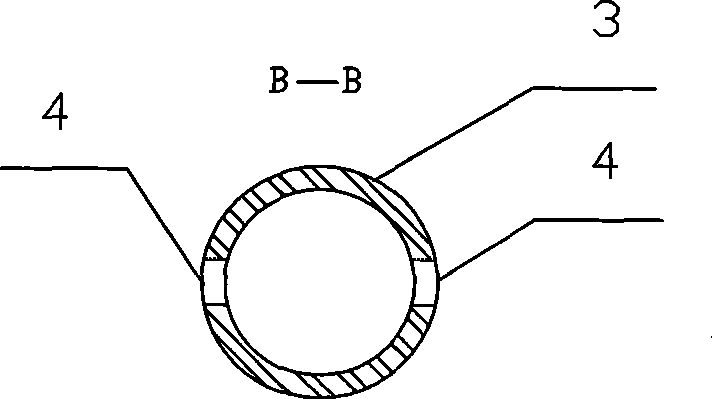

Embodiment 1

[0019] Example 1: A rail transit end well shield enters the tunnel (uplink), and there is a large sand gushing and water spray phenomenon when drilling the exploratory hole at the gate. The well part at the end of the line is reinforced by horizontal freezing. The freezing pipe and liquid supply pipe used in the end well part are 20# low-carbon steel seamless steel pipes. The liquid supply pipe is provided with air holes with a distance of 300mm, arranged in a plum blossom shape, and the diameter of the air holes is 3mm. The bottom of the liquid supply pipe 3 is connected There is a sealing plate 6 with one hole, the sealing plate 6 is 100mm away from the bottom of the freezing tube 5, and a plurality of temperature measuring holes are set at the part of the frozen tube extending 700mm outward in the end well, and the effective depths of the temperature measuring holes are 0.2m and 2.4m A total of 2 temperature measuring points are arranged, among which the temperature values ...

Embodiment 2

[0021] The PHC pile foundation of a high-speed railway penetrated the tunnel segment between ring 510 and ring 520 on the downlink of the tunnel in the shield section, causing soil to enter the tunnel, resulting in local deformation and cracks in the tunnel. A liquid nitrogen freezer was used to damage the tunnel The formation is reinforced by horizontal freezing. The freezing pipe and the liquid supply pipe are made of stainless steel pipes. The vent holes on the liquid supply pipe are set from the hole depth of 12m, with a distance of 400mm, arranged in a plum blossom shape, and the diameter of the vent holes is 6mm. The bottom of the liquid pipe 3 is 200mm away from the bottom of the freezing pipe 5, and there are 3 ventilation holes on the sealing plate 6. A plurality of temperature measuring holes T are set near the freezing pipe in the damaged formation of the tunnel, and temperature measuring probes are placed under the temperature measuring holes. There are at least 4 t...

Embodiment 3

[0023] For a dedicated traffic link project on a rail transit line, the shield exits the tunnel at the south end of the well, and the vertical liquid nitrogen freezing body is used to reinforce the tunnel door area. The freezing pipe is made of stainless steel, and the liquid supply pipe is made of low-carbon seamless steel pipe. Ventilation holes are arranged at a depth of 20m, the spacing of the ventilation holes is 800mm, and the diameter of the ventilation holes is 8mm, arranged in a plum blossom shape; the bottom of the liquid supply pipe 3 with the sealing plate 6 is 100mm away from the bottom of the freezing pipe 5, and there are 2 ventilation holes on the sealing plate 6 , set multiple temperature measuring holes at corresponding positions, place temperature measuring probes under the temperature measuring holes, set at least 4 temperature measuring points in each temperature measuring hole, and the depths of the four temperature measuring points in one temperature measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com