Urethane resin-coated controlled release fertilizer

A technology of polyurethane resin and coated controlled-release fertilizer, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of scientific fertilization technology, low education level, low mechanization degree, etc., and achieve significant increase in production and synergy , Extensive promotion and application prospects, and the effect of reducing the loss rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

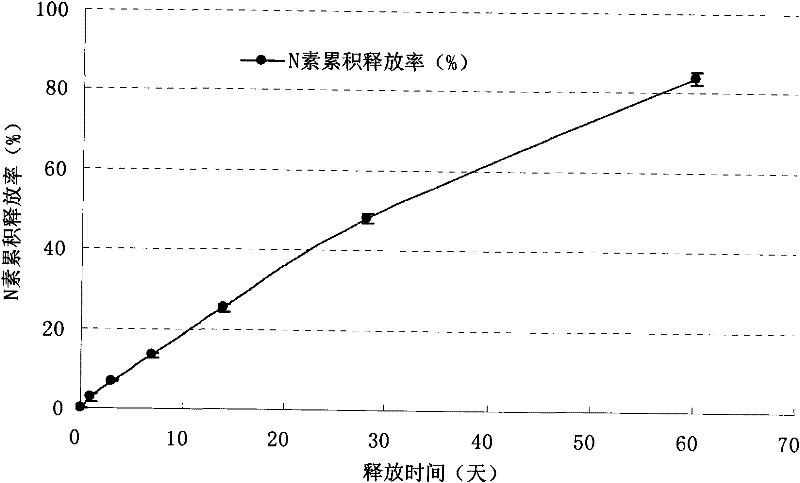

[0018] Embodiment 1 Production of controlled release period 2 months polyurethane controlled release urea (44-0-0)

[0019] Weigh 13.5kg of polymeric MDI, 3kg of industrial paraffin oil, 12kg of tung oil and 1.5kg of light calcium carbonate, add them to 3kg of xylene and stir evenly, configure the coating solution, and put 1000kg of large particle urea (2.0-4.75mm) in the spray In the fluidized bed, the hot air is used to preheat to 45-48°C, and the hot gas is used in the coating equipment. The coating liquid is sprayed on the surface of the suspended and fluidized urea particles through the nozzle. Under the action of the hot air, The solvent evaporates quickly, and the coating material is wrapped on the surface of the fertilizer particles to form a dry, smooth and dense film layer. After continuous spraying of the coating solution, polyurethane with a coating rate of about 3% and a controlled release period of 2 months is obtained until the coating process is completed. Cont...

Embodiment 2

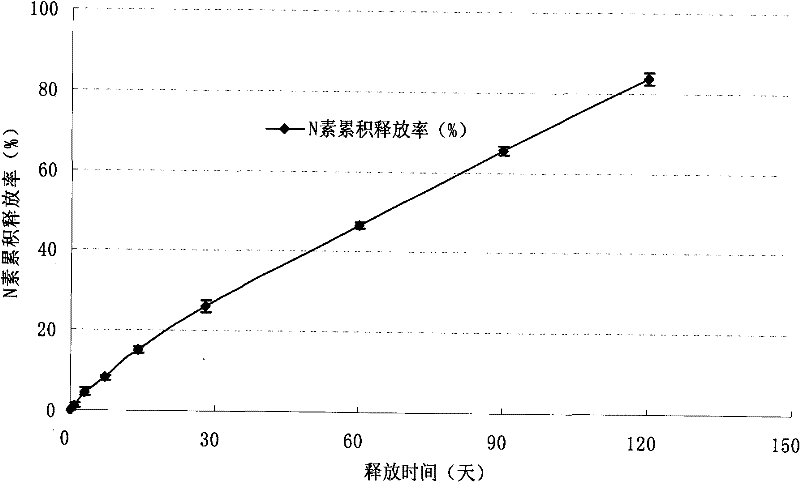

[0020] The making of embodiment 2 controlled release period 4 months polyurethane controlled release compound fertilizer (14-14-14)

[0021] Weigh 23.8kg of polymeric MDI, 4.76kg of industrial paraffin oil, 19kg of tung oil and 2.38kg of light calcium carbonate, add them in turn to 7.5kg of xylene and stir evenly. In the sprayed fluidized bed, hot air is used to preheat to 48-52°C, and in the coating equipment, hot gas is used to set off, and the coating liquid is sprayed onto the surface of the suspended and fluidized urea particles through the nozzle, and the hot air Under the environment, the solvent evaporates quickly, and the coating material is wrapped on the surface of the fertilizer particles to form a dry, smooth and dense film layer. After continuous spraying of the coating solution, the coating rate is about 5% until the coating process is completed. The controlled release period is 4 months. Polyurethane controlled-release compound fertilizer (14-14-14), the volati...

Embodiment 3

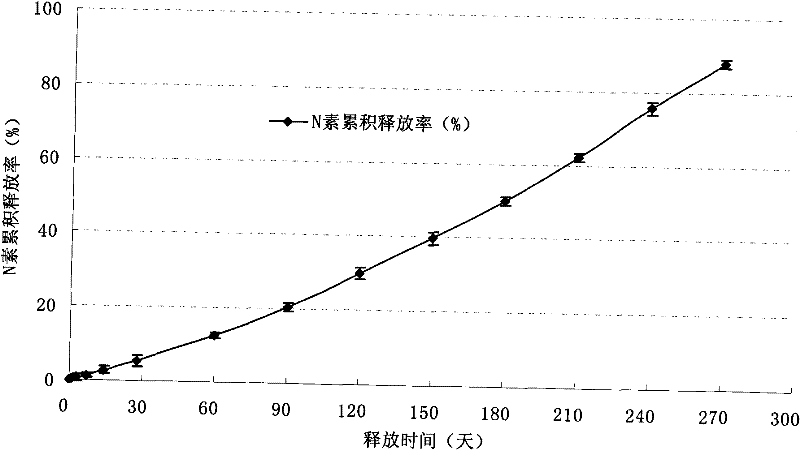

[0022] The making of embodiment 3 controlled-release period 9 months polyurethane controlled-release compound fertilizer (20-8-10)

[0023] Weigh 38.5kg of polymeric MDI, 7kg of industrial paraffin oil, 28kg of tung oil and 3.5kg of light calcium carbonate, add them to 15.4kg of xylene and stir evenly, configure the coating solution, and put 1000kg of granular compound fertilizer (2.0-4.75mm) in the In the spouted fluidized bed, hot air is used to preheat to 52-57°C, and in the coating equipment, hot gas is used to set off the coating liquid. , the solvent evaporates quickly, and the coating material is wrapped on the surface of the fertilizer particles to form a dry, smooth and dense film layer. After continuous spraying of the coating solution, until the coating process is completed, the coating rate is about 7% and the controlled release period is 9 months. Polyurethane controlled-release compound fertilizer (20-8-10), the volatilized solvent can be recovered and recycled. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com