Sprinkler tube plate laser bonder

A technology of adhesives and water spray belts, applied in the field of hot-melt bonding, can solve the problems of uneven winding, affecting the stability of winding, affecting the appearance of products, etc., and achieve the effect of smooth and flat surface, flat and beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

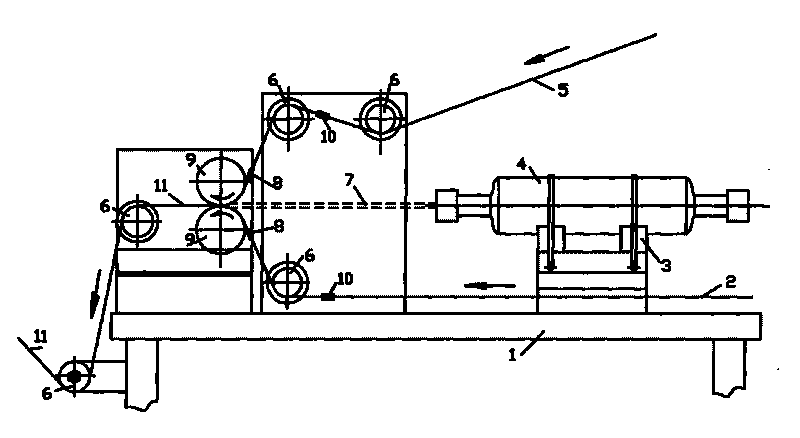

[0030] see first figure 1 , a kind of laser bonder with water spray belt sheet provided by the present invention, comprises workbench, support, laser gun, guide wheel, pressure roller, wherein support 3 and workbench 1 are connected as a whole, and laser gun 4 is fixed on On the support 3, the two pressure rollers 9 are parallel to each other, close to each other, and rotate in opposite directions. The direction of the laser beam emitted by the laser gun 4 points to the position close to the two ends of the contact seam of the two pressure rollers 9. The guide wheels 6 are respectively arranged with The up and down of the laser beam are parallel to the pressure roller, and the adjacent guide wheels or between the guide wheel and the pressure roller rotate in reverse.

[0031] In addition, a cleaning splint 10 can be arranged in front of the pressure roller 9 to remove impurities or dirt on the surface of the belt. Also guide groove 8 should be set before pressure roller 9, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com