Underwater remote-control welding system

An underwater remote control and welding system technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of high labor input cost and the underwater remote control welding system has not yet appeared, which is conducive to the elimination of welding fumes and improved performance. The effect of the clarity of the camera and the simplified sealing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

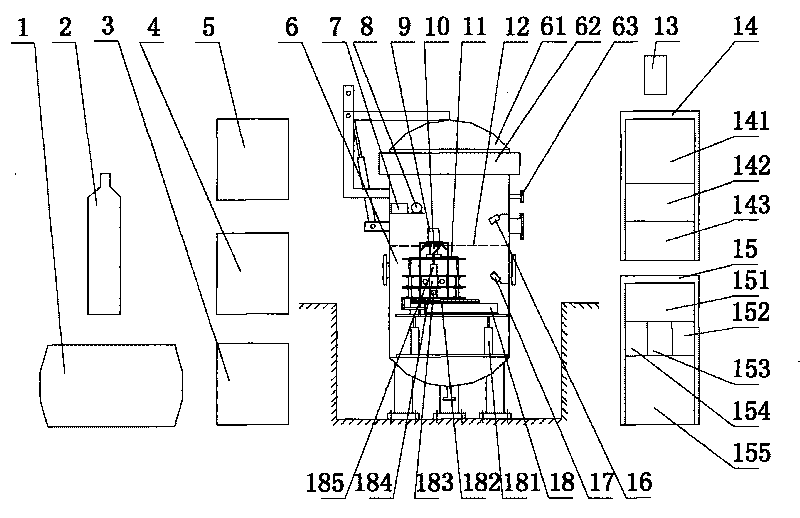

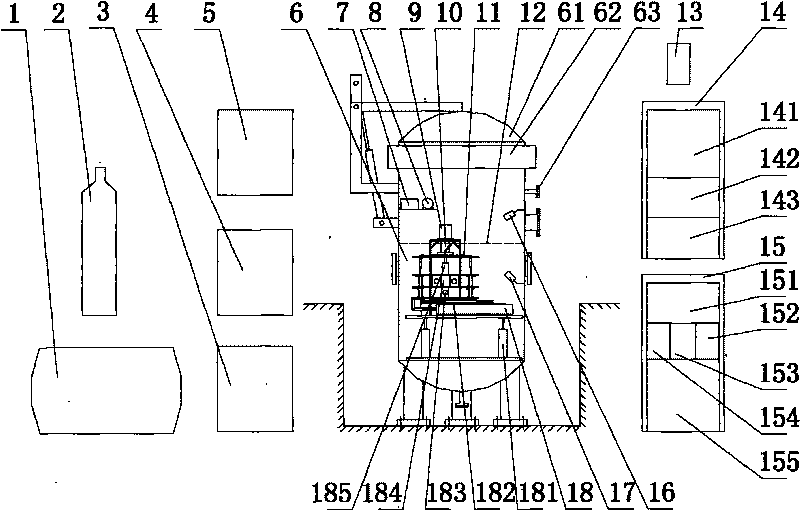

[0021] Depend on figure 1 It shows an underwater remote control welding system, which mainly consists of air compressor 1, Ar gas cylinder 2, test chamber hydraulic station 3, welding power supply 4, welding platform hydraulic station 5, underwater welding test chamber 6, welding platform valve group 7. Wire feeder 8, underwater welding camera 9, drainage air cover 10, test steel plate 11, water surface 12, welding manual control box 13, control system cabinet 14, monitoring TV cabinet 15, water surface camera 16, underwater camera 17 and The welding platform 18 consists of: the underwater welding test chamber 6 is filled with water to the water surface 12, the welding platform valve group 7, the wire feeder 8, the underwater welding camera 9, the drainage air cover 10, the test steel plate 11, the water surface camera 16, the water surface The lower camera 17 and the welding platform 18 are installed in the underwater welding test cabin 6, the air compressor 1, the Ar gas cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com