Layout methodology that automates layout rule verification for differential signal trace pairs

A differential signal and layout method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor quality of printed circuit boards and reduce the work efficiency of layout engineers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

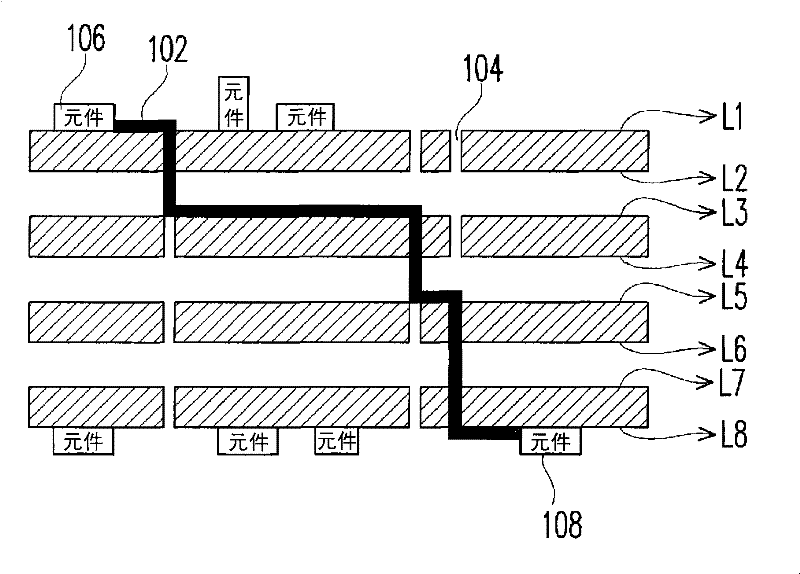

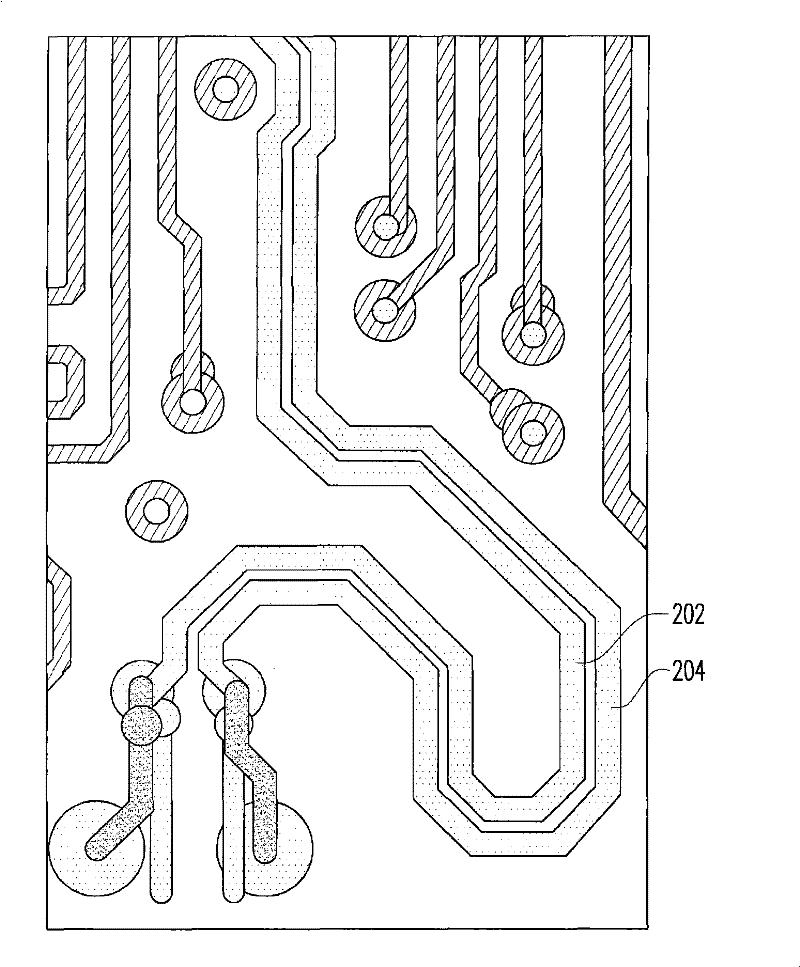

[0016] In order to facilitate the comparison with the conventional layout method and make it easier for readers to understand the present invention, the following embodiments will first assume that there is already a layout software that uses a program based on the layout method of the present invention, and will also be combined with the accompanying drawings. The present invention will be described in detail.

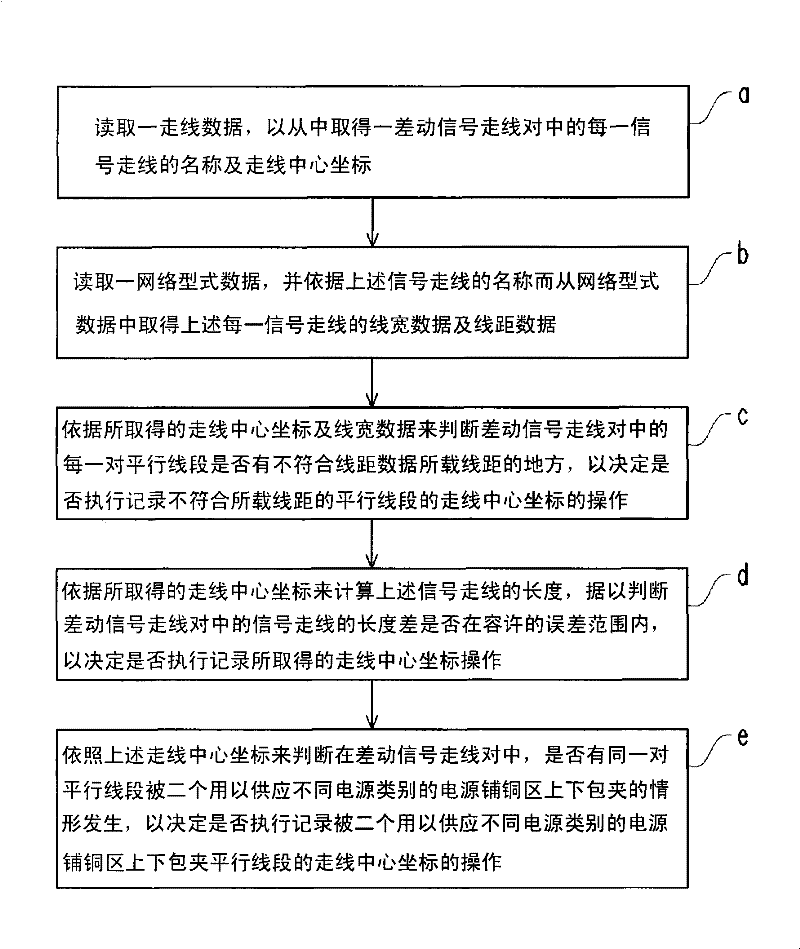

[0017] Assuming that a layout engineer is using this layout software, in the process of operation, the layout software will determine whether the layout engineer further requires automatic execution of the layout rule verification operation of the differential signal wiring pair. If the judgment is yes, the layout software will execute the aforementioned program based on the layout method of the present invention to automatically execute the layout rule verification of the differential signal wiring pair. The layout software automatically executes the layout rule check o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com