Multipath circulating fluidized bed boiler

A circulating fluidized bed, multi-process technology, used in fluidized bed combustion equipment, incinerators, and fuels burned in a molten state, can solve the problems of difficult to achieve material separation effect, easy to form material accumulation, etc., to ensure long-term normal operation. The effect of running, avoiding long-term accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

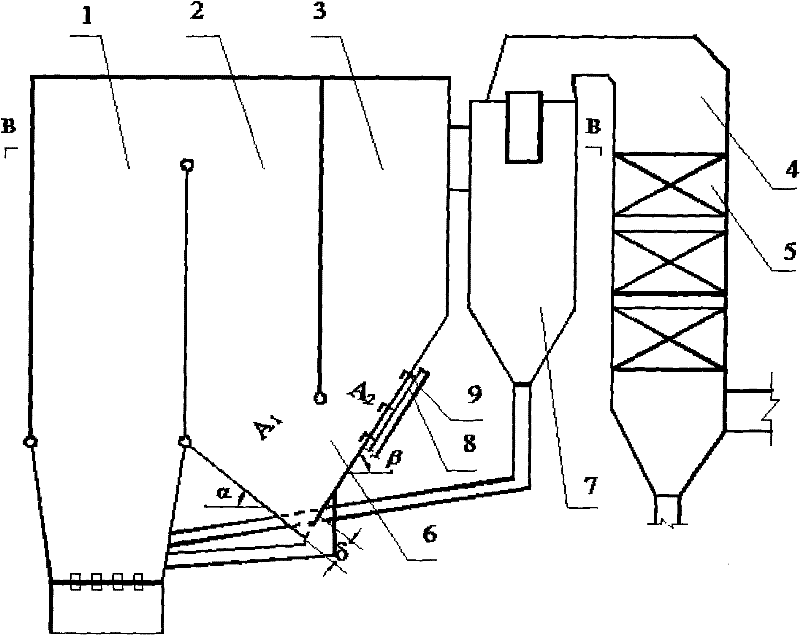

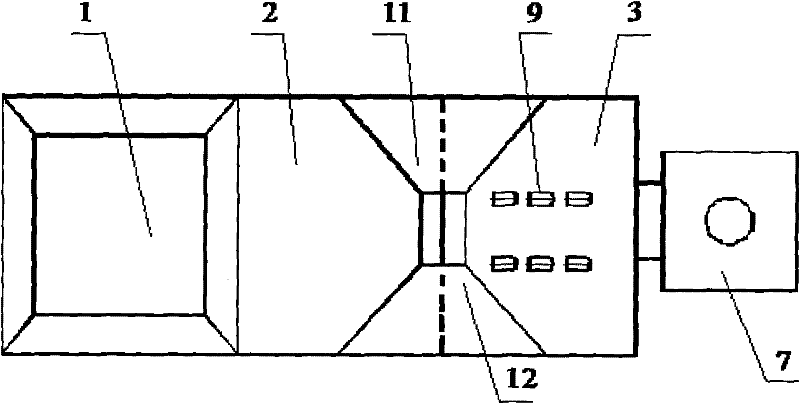

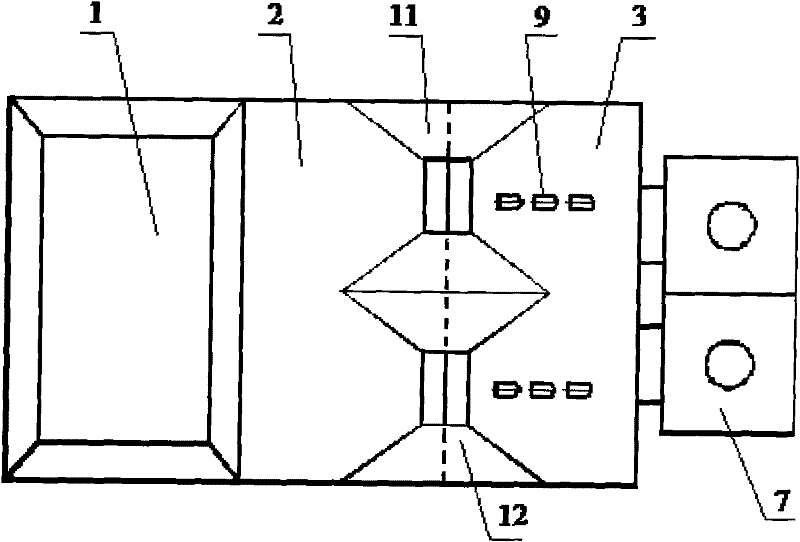

[0017] A multi-process circulating fluidized bed boiler, including a main combustion chamber 1, an auxiliary combustion chamber 2, an ember chamber 3, a tail flue (4), an economizer, a primary material separation and circulation device, a secondary material separation and circulation device, etc. The auxiliary combustion chamber 2 and the ember chamber 3 are arranged side by side with the main combustion chamber 1, and the combustion chambers are separated by membrane walls. Gas and material passages are left in the upper part of the main combustion chamber 1 and the auxiliary combustion chamber 2, and gas and material passages are reserved in the lower parts of the auxiliary combustion chamber 2 and the ember chamber 3.

[0018] The membrane wall (bottom surface) at the bottom of the auxiliary combustion chamber 2 is inclined, and the direction is inclined to the ember chamber 3, and the inclination angle (the included angle with the horizontal direction) α is 30°~60°. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com