Screw-thread backflow prevention device being free from being equipped with external conduit

A backflow preventer, thread-type technology, applied in the direction of functional valve type, valve operation/release device, valve details, etc., can solve problems such as difficulty in determining backflow water, hidden dangers of water supply safety, easy loss, etc., to facilitate observation. And the effect of rapid replacement, ensuring water supply safety and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

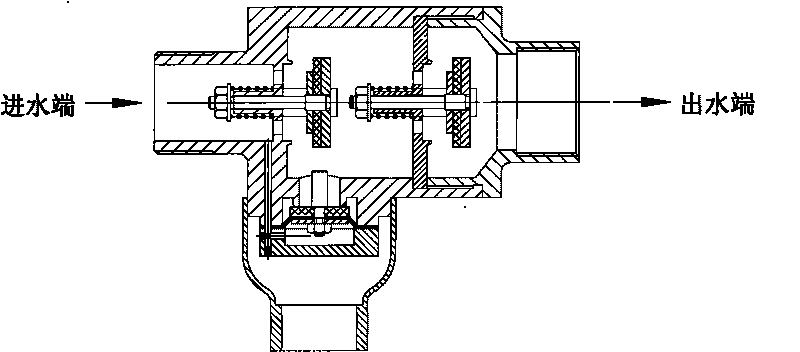

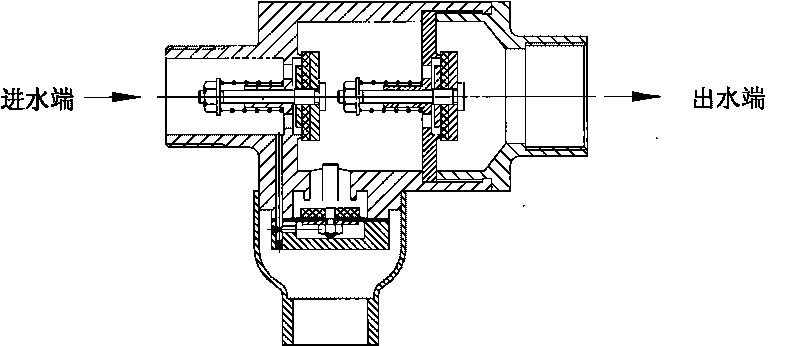

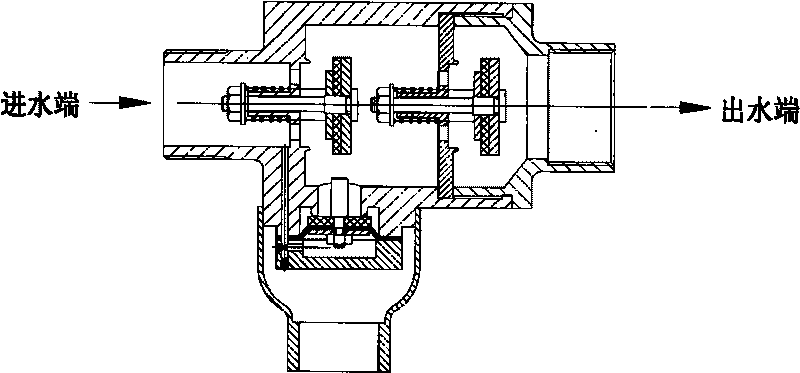

[0008] The structure of the screw-type backflow preventer without an external catheter of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0009] The screw-type backflow preventer that does not need an external conduit is a structure that has a major breakthrough in the technical field.

[0010] Such as figure 1 , 2 as shown, figure 1 The middle arrow indicates the direction of medium flow. A screw type backflow preventer, the backflow preventer includes a water inlet check drain valve, a water outlet check valve and an interface, and is characterized in that the valve body of the water inlet check drain valve is one (1) and the valve body two (8) of the water outlet check valve are fastened and communicated; the valve stem one (2) of the water inlet check drain valve is respectively arranged on the water inlet of the valve body one (1), and when the valve is opened, the Valve plate one (4) moves to the right, and whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com