Asynchronous sinking construction method of separated steel cofferdam of large-scale bridge base

A technology of bridge foundation and construction method, which is applied in basic structure engineering, caisson, construction, etc., can solve the problems of low mud suction efficiency, excessive earth pressure deviation, tearing of weld seams, etc. Bit accuracy, safe sinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

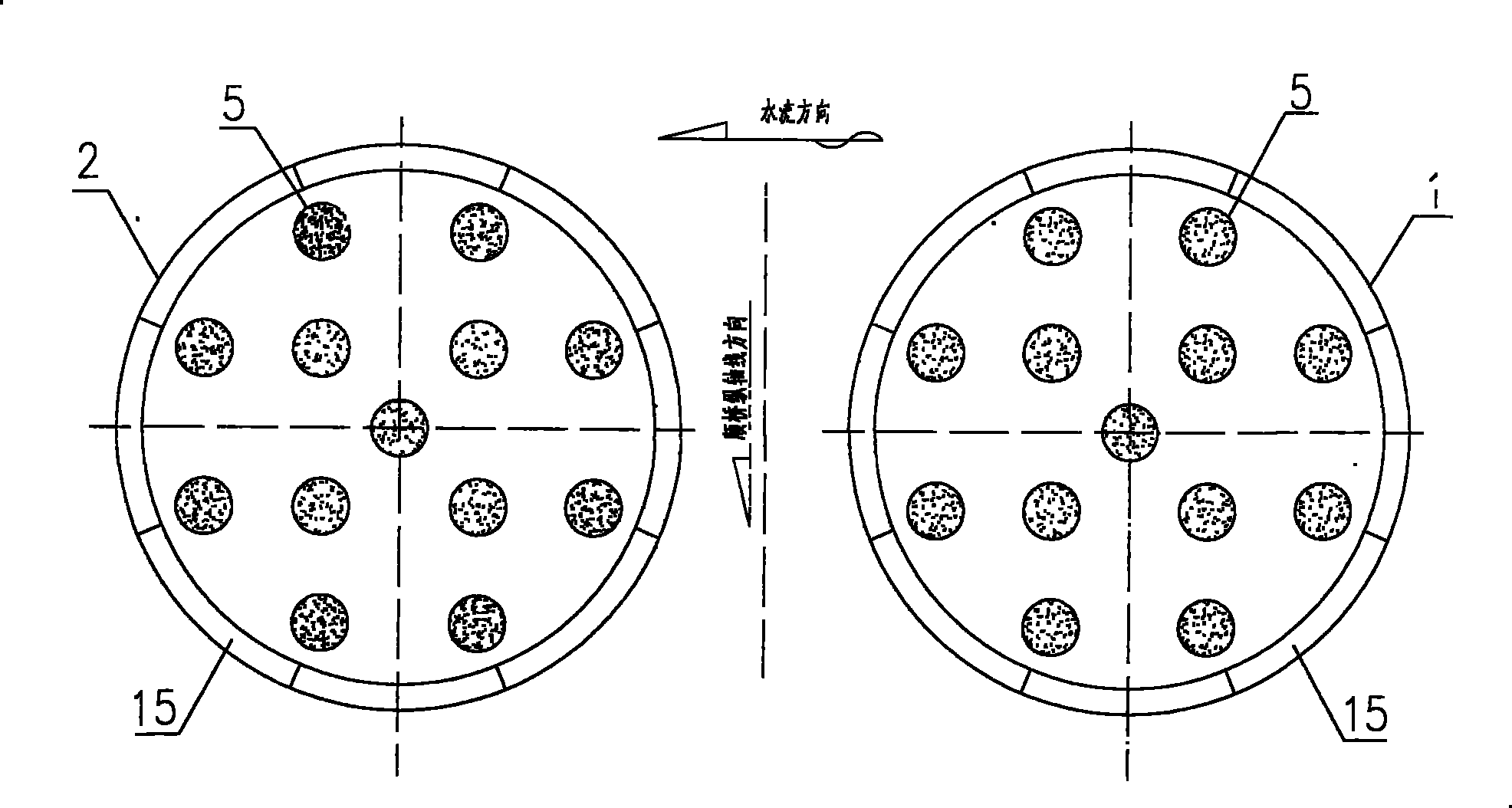

[0026] The subsidence of the extra-large separated double-wall steel cofferdam of the No. 28 main pier of the Jingyue Yangtze River Bridge. Jingyue Yangtze River Bridge is a steel box girder twin-tower cable-stayed bridge with a main span of 816m. The north cable tower (main pier No. 28) is located on the bank of the Yangtze river bed and is designed as a separate circular steel cofferdam pile cap foundation. The diameter of the platform cap reaches 30m, and the outer diameter of the steel cofferdam is 33m.

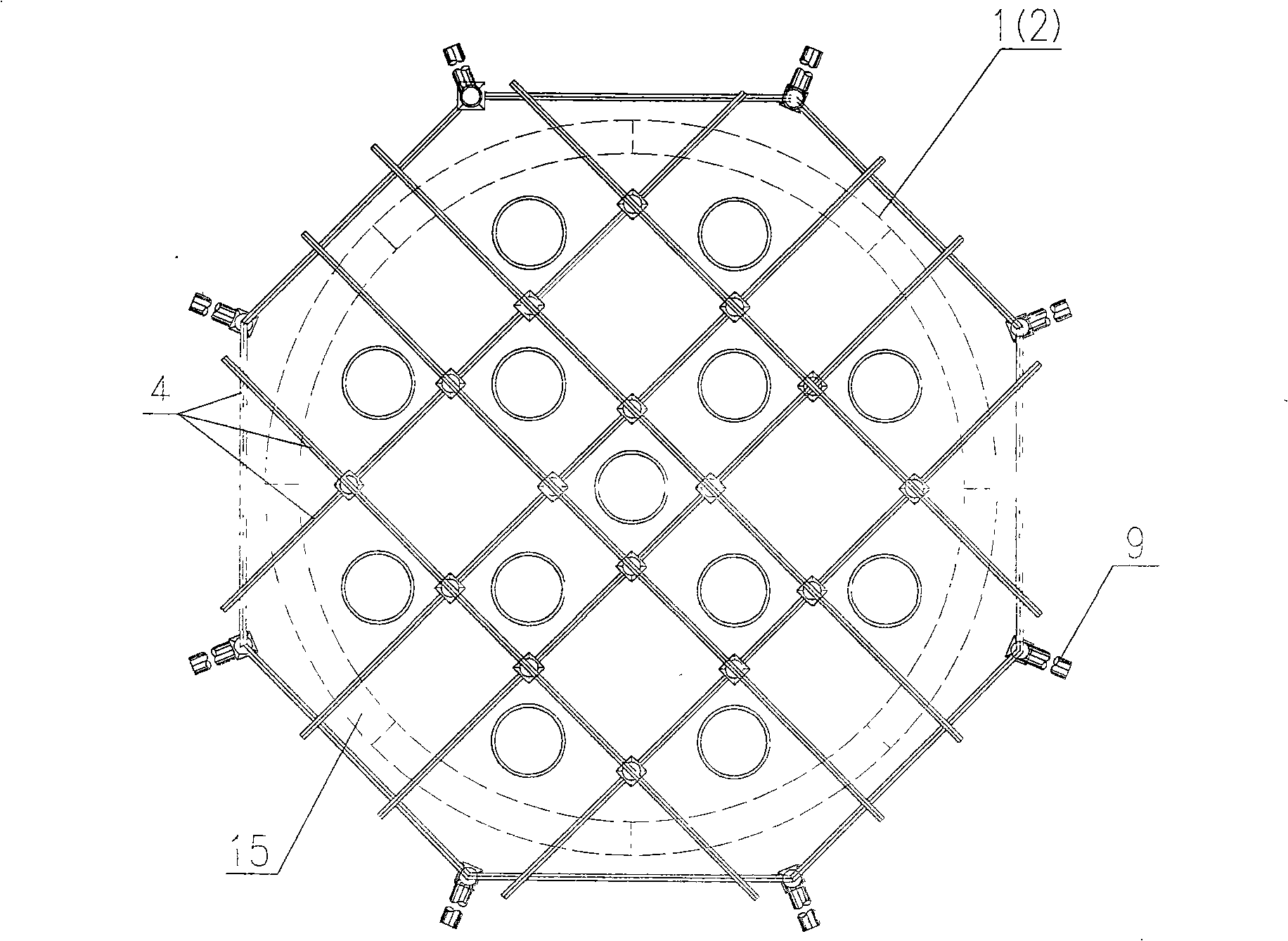

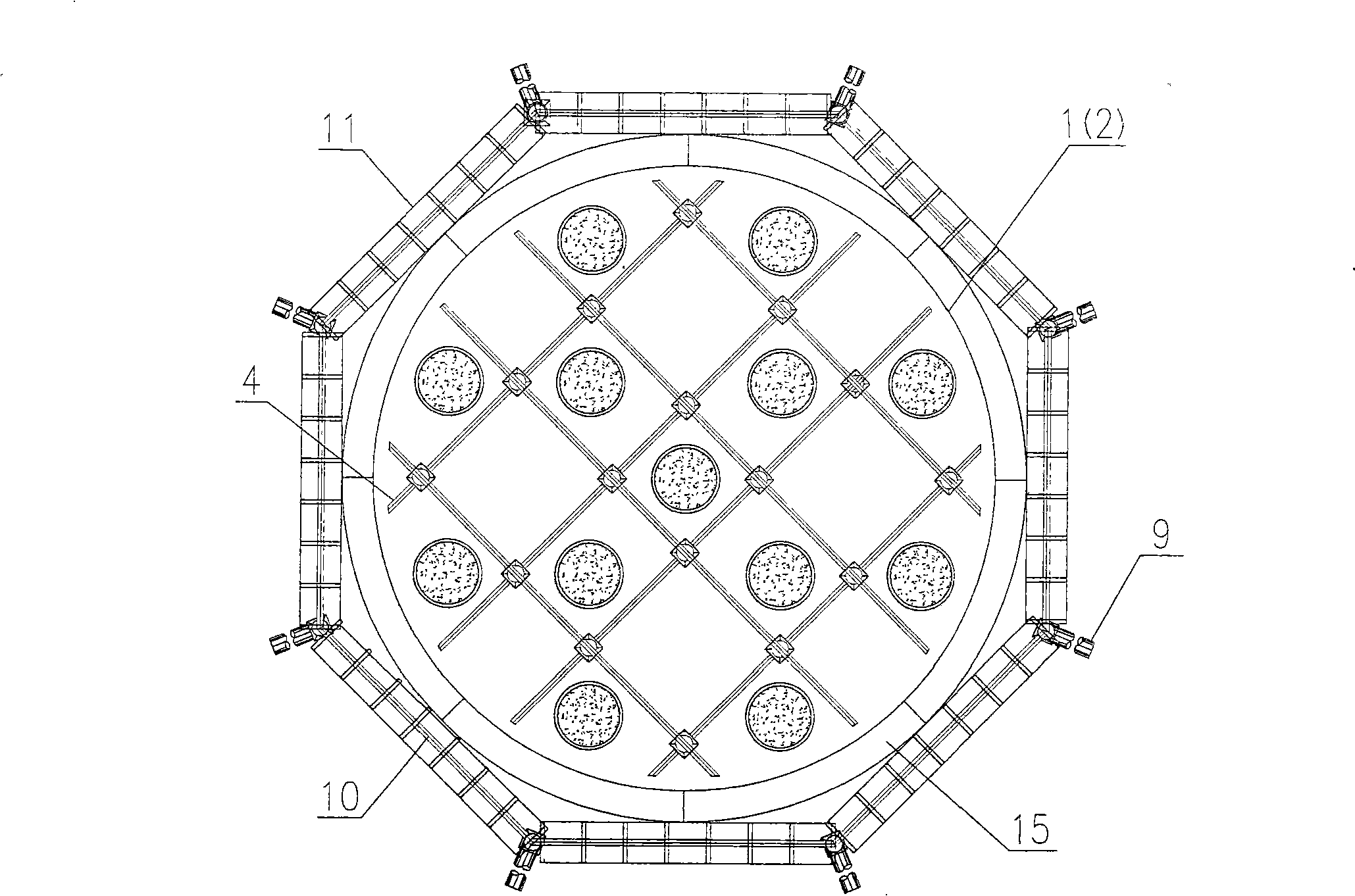

[0027] like Figure 1-6 As shown, the large-scale bridge foundation separation type steel cofferdam asynchronous sinking construction method of the present invention first sinks the downstream steel cofferdam 1 and then sinks the upstream steel cofferdam 2. , The inner side positioning guide device 7 and the outer side positioning guide device 17 are arranged on the outer side. In this way, the interference of turbulent flow between the two steel cofferdams 1 and 2 can ...

Embodiment 2

[0042] like Figure 1-6 As shown, in the asynchronous subsidence construction method of a large bridge foundation separated steel cofferdam of the present invention, except that the angle α between the first I-beam 12 and the second I-beam 13 of the inner positioning guide device 7 is 30° , all the other are identical with embodiment 1.

Embodiment 3

[0044] like Figure 1-6 As shown, in the large bridge foundation separation type steel cofferdam asynchronous sinking construction method of the present invention, except that the angle α between the first I-beam 12 and the second I-beam 13 of the inner positioning guide device 7 is 90° , all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com