Preparation method of carboxymethylated bagasse xylan derivative

A carboxymethylation and xylan technology, which is applied in the field of preparation of carboxymethylated bagasse xylan derivatives, can solve the problems of poor solubility of bagasse xylan, narrow application range and the like, and achieves safe and free raw material utilization. Toxic, high utilization rate of raw materials, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

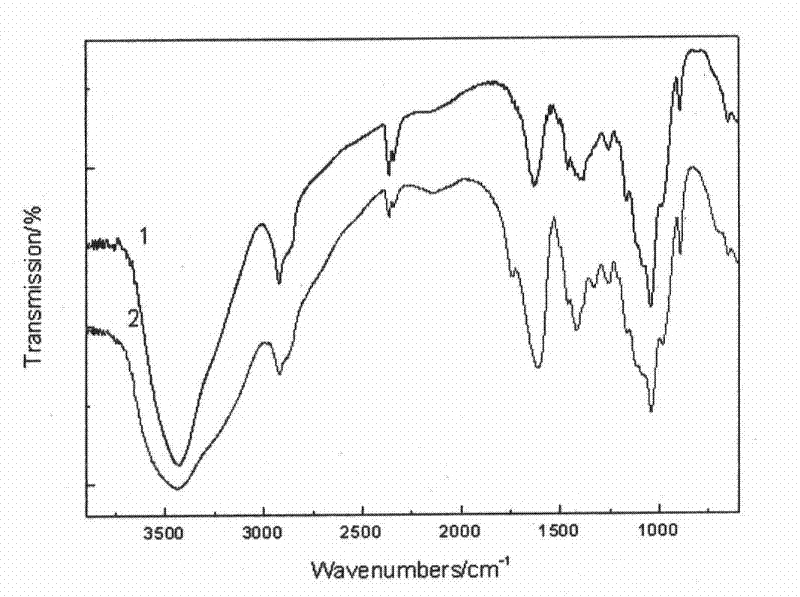

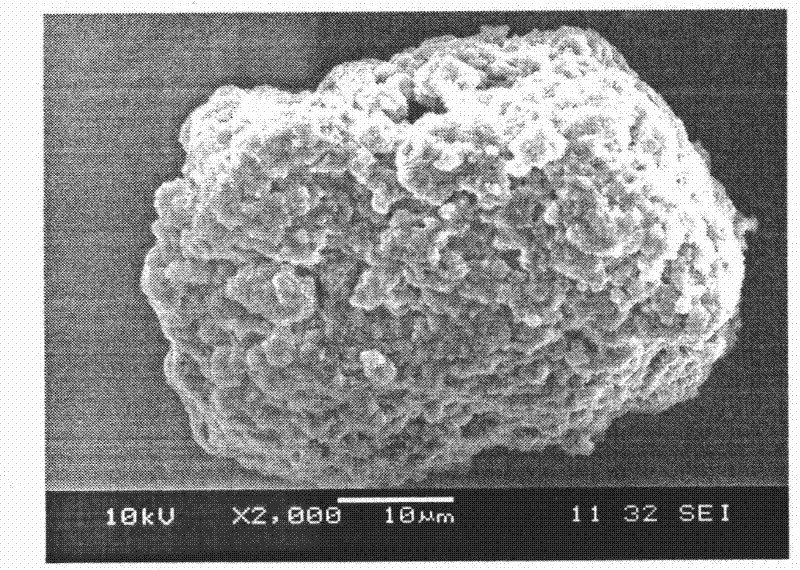

Image

Examples

Embodiment

[0025] (1) Mix analytically pure ethanol, analytically pure petroleum ether and water in a volume ratio of 6:3:1 to obtain a solvent; bagasse xylan, monochloroacetic acid and sodium hydroxide are fed in a mass ratio of 1:0.89:0.9 , Monochloroacetic acid and sodium hydroxide are first dissolved with 6 times and 2 times the corresponding mass of the above solvent for subsequent use;

[0026] (2) Get 21g of bagasse xylan and 105g of the above-mentioned solvent and stir evenly, get half of the sodium hydroxide solution prepared in step (1), add it dropwise in the reaction system, adjust the rate of addition, and control the pH value of the system at 9~12 Between, react at 45 ℃ for 2 hours;

[0027] (3) Add 0.06 g of metallocene catalyst, drop the above-mentioned monochloroacetic acid solution and the remaining sodium hydroxide solution to the reaction system respectively, control the pH value of the system between 9 and 12, and react at 65° C. for 3 hours;

[0028] (4) adding dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com