Method for preparing cationic grafting agent with multi-reactive groups

A cationic and grafting agent technology, applied in the field of preparation of chemicals for textile modification, can solve the problems of poor dyeing effect of blended fabrics, difficulty in popularization, dyeing pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

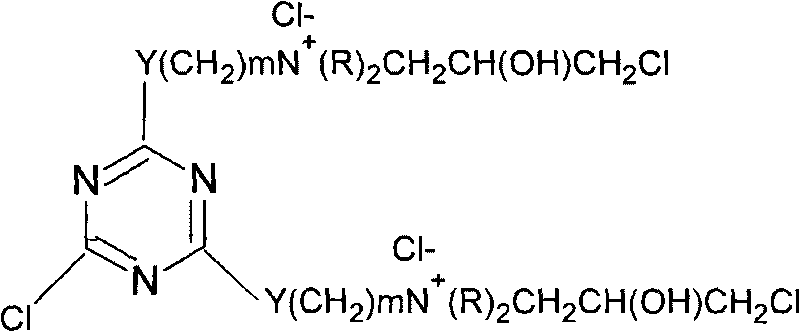

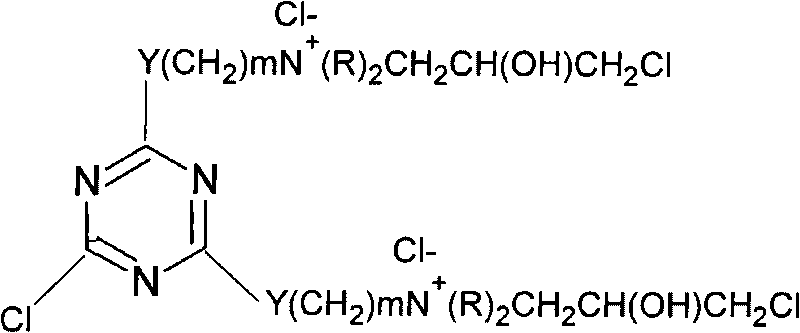

Image

Examples

Embodiment 1

[0017] Chloro-triazine ammonium chloride derivative——2,4-di-[2-hydroxy-3-chloropropyl-dimethylaminopropylamino]-6-chloro-triazine ammonium chloride preparation:

[0018] Add 1 mole of cyanuric chloride to a three-neck flask with 200 g of ice water solution, a stirrer, and a thermometer, and slowly add 0.34 mole of N, N-dimethylpropylenediamine dropwise under stirring conditions at 0-5 ° C. Hydrochloride, with Na 2 CO 3 Adjust and control the pH value to 3-4, stir until the pH of the reaction solution remains constant, raise the temperature to 40-45°C, add 0.34mol of N,N-dimethylpropylenediamine hydrochloride under stirring, and use Na 2 CO 3 Adjust and control the pH value to 5-6, stir and react for 1.5h, add 15ml of 35% hydrochloric acid solution dropwise, then slowly add 0.7mol of epichlorohydrin dropwise, raise the temperature to 85°C after the addition, and keep the temperature for 4h to obtain the content It is a 32% solution of 2,4-bis-[2-hydroxy-3-chloropropyl-dimet...

Embodiment 2

[0022] Chloro-triazine ammonium chloride derivative——2,4-di-[2-hydroxy-3-chloropropyl-dimethylaminopropoxy]-6-chloro-triazine ammonium chloride preparation:

[0023] Add 1 mole of cyanuric chloride to a three-neck flask with 200 g of ice water solution, a stirrer and a thermometer, and slowly add 0.34 mole of 3-N, N-dimethylaminopropanol dropwise under stirring at 0-5 °C Hydrochloride, with Na 2 CO 3 Adjust and control the pH value to 3-4, stir until the pH of the reaction solution remains constant, raise the temperature to 40-45°C, and add 0.34mol of 3-N,N-dimethylaminopropanol hydrochloride under stirring, use Na 2 CO 3 Adjust and control the pH value to 5-6, stir and react for 1.5h, add 15ml of 35% hydrochloric acid solution dropwise, then slowly add 0.7mol of epichlorohydrin dropwise, raise the temperature to 85°C after the addition, and keep the temperature for 4h to obtain the content It is a 32% solution of 2,4-bis-[2-hydroxy-3-chloropropyl-dimethylaminopropoxy]-6-c...

Embodiment 3

[0027] Monochloro-triazine ammonium chloride derivative——2,4-di-[2-hydroxy-3-chloropropyl-dimethylaminoethoxy]-6-chloro-triazine ammonium chloride preparation:

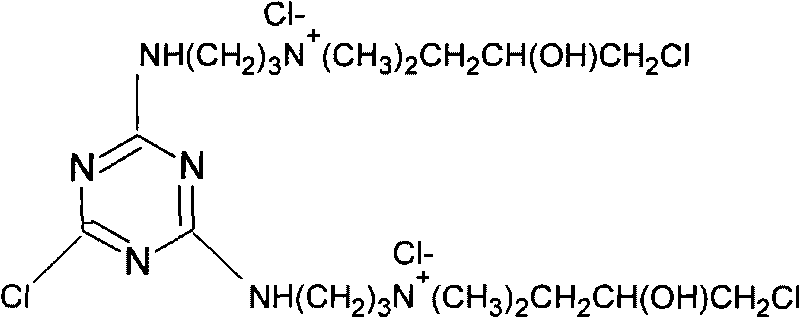

[0028] The raw material 3-N that is added for the first time and the second time of embodiment 2, N-dimethylaminopropanol is changed into 3-N, N-dimethylaminoethanol, other conditions are identical with example 8, and the prepared content is 32% solution of 2,4-bis-[2-hydroxy-3-chloropropyl-dimethylaminoethoxy]-6-chloro-triazine in ammonium chloride. The solution is a colorless transparent liquid. The solution was evaporated, DMF recrystallized, IR, HNMR proved the product structure as follows

[0029]

[0030] The product does not need to be separated and purified, and can be directly applied to the modification of cellulose fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com