Process for treating acid wastewater in mine and reclaiming valuable metals in wastewater

A technology for mine acidic wastewater and valuable metals, applied in the field of water treatment, can solve problems such as low sulfate reduction efficiency, achieve the effects of reducing inhibition, rapid separation, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

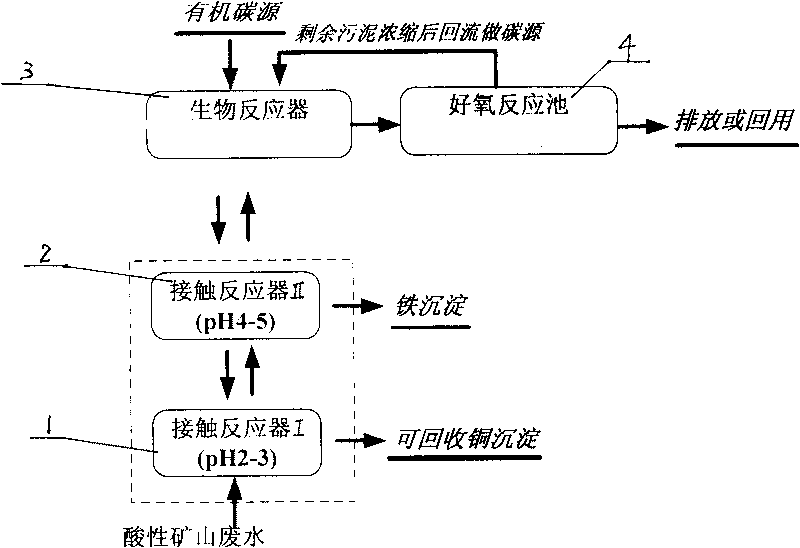

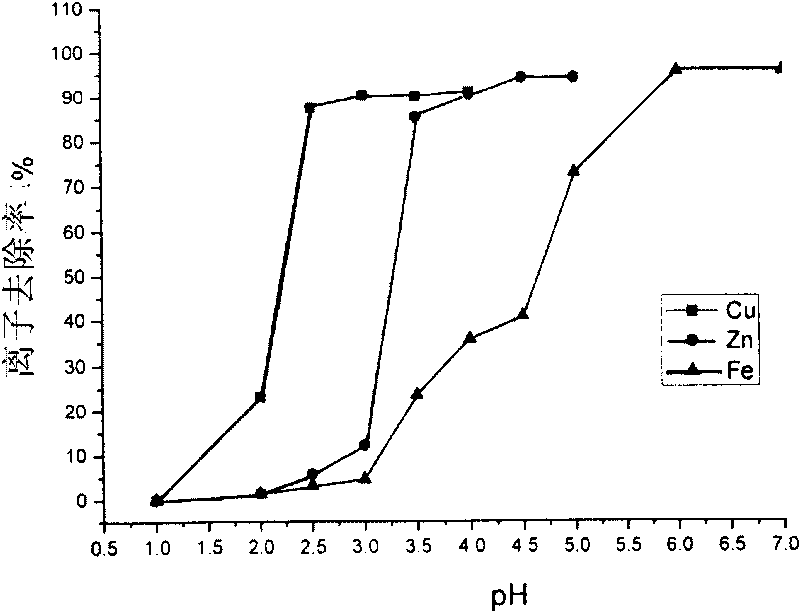

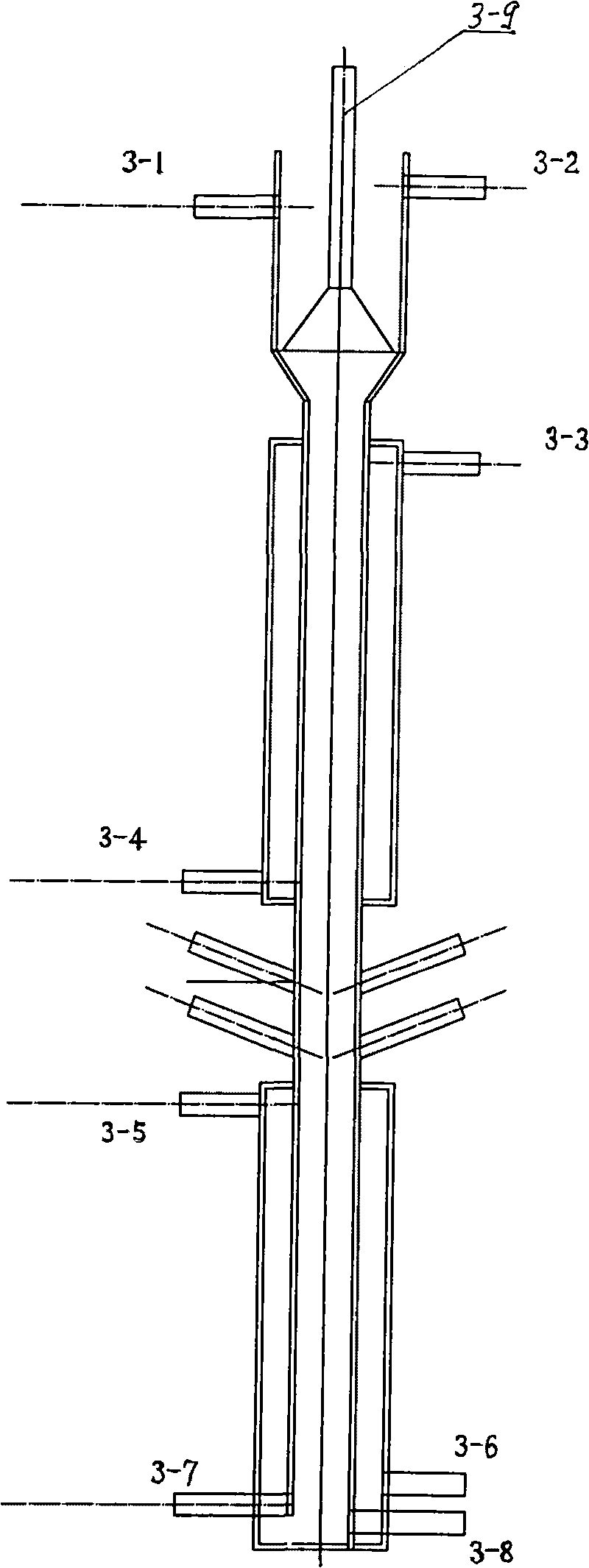

[0032] The volume of the UASB bioreactor is 3L, the volumes of the contact reactor 1 and the contact reactor 2 are 10L, and the volume of the aerobic reactor is 1L. Concentrate 5L of excess sludge from the urban sewage treatment plant to 2.5L (the sludge concentration is 5000mg / L) and pour it into the bioreactor. Take molasses wastewater (COD100000) and dilute it 100 times, pump it into the bioreactor at a flow rate of 200mL / h, and run it continuously for 10 days. Contact reactor 1, contact reactor 2 is filled with tap water, press figure 1 The connection shown is good, the pH2-3 mine acid wastewater (Cu 2+ 0.2g / L; Fe 2+ , 1.0-2.0g / L; Fe 3+ , 3g / L, SO 4 2- , 3g / L) into the contact reactor at a flow rate of 100mL / h, a reflux is set between the contact reactor I and the contact reactor II, and a reflux is set between the contact reactor II and the bioreactor, wherein the contact reaction The reflux flow rate between the reactor I and the contact reactor II was 200mL / h, an...

Embodiment 2

[0034] The volume of UASB bioreactor is 3L, the volume of contact reactor I and contact reactor II is 10L respectively, and the volume of aerobic reactor is 1L. Concentrate 5L of the remaining sludge from the urban sewage treatment plant to 2.5L and pour it into the bioreactor. Take alcohol wastewater (COD100000) and dilute it 100 times, pump it into the bioreactor at a flow rate of 200mL / h, and run it continuously for 10 days. Contact reactor I, contact reactor II is full of tap water, press figure 1After the connection is completed, the pH2-3 mine acid wastewater (Cu2+.2 / L; Fe2+, 1.0-2.0g / L; Fe3+, 3g / L, SO42-, 3g / L) is passed into the contact at a flow rate of 100mL / h Reactor, reflux is set between contact reactor I and contact reactor II, and reflux is set between contact reactor II and bioreactor, wherein the reflux flow rate between contact reactor I and contact reactor II is 200mL / h, the reflux flow rate between the contact reactor II and the bioreactor is 2L / h, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com