Antistatic collection box for circuit board

A technology of electrostatic collection and collection box, which is applied in the direction of preventing mechanical damage, rigid container, container, etc. It can solve the problems that the width and length of the circuit board cannot be solved at the same time, increase the operation time, and waste the space of the box. Adjusting time and complex adjustment process, avoiding damage, avoiding collision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

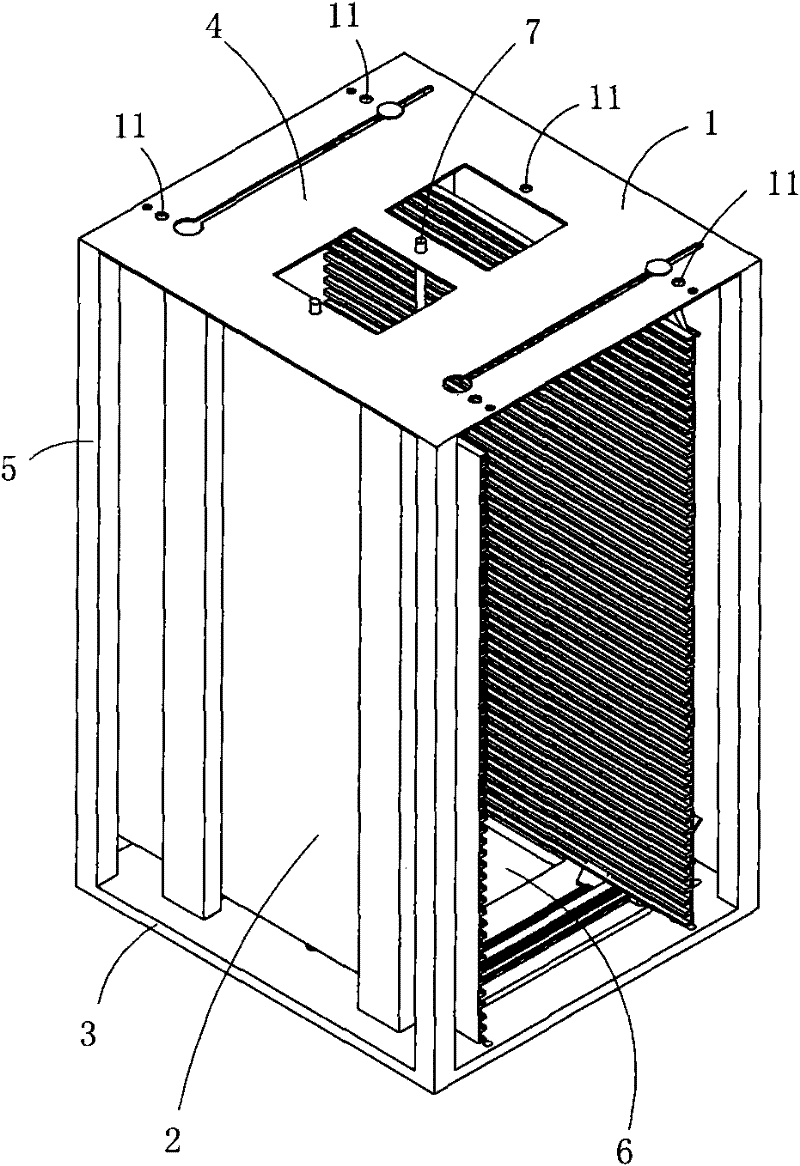

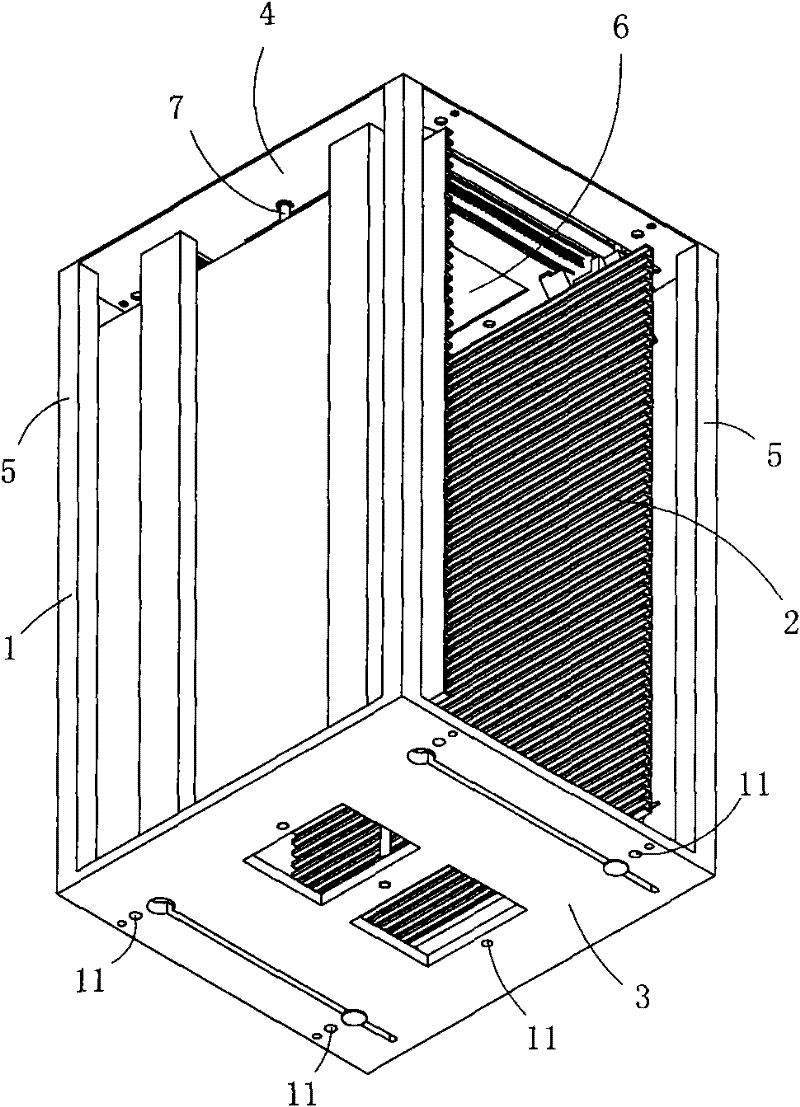

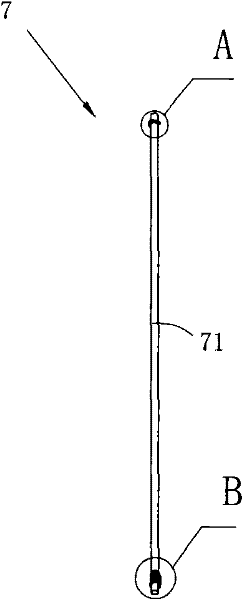

[0026] Figure 1 to Figure 5 A specific embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the first structure of the present invention; figure 2 Yes figure 1 The schematic diagram of the three-dimensional structure of the circuit board anti-static collection box when viewed from another angle; image 3 Yes figure 1 A schematic diagram of a three-dimensional structure of the space dividing device in the circuit board anti-static collection box shown; Figure 4 Yes image 3 A partially enlarged schematic diagram of A in the shown space division device; Figure 5 Yes image 3 Partial enlarged schematic diagram of B in the space division device shown.

[0027] This embodiment is a circuit board anti-static collection box, see Figure 1 to Figure 5 , including a collection box body 1 , a rail-type material rack 2 arranged in the collection box body 1 , and a space dividing device 7 . The collection box bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com