Moulding stamper for magnetic shoe of permanent magnet DC motor stator and using method thereof

A motor stator and permanent magnet DC technology, which is applied in the field of forming and pressing molds, can solve the problems of temperature rise, small difference in the size of the magnetic field in the center of the magnetic tile, and low magnetic utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

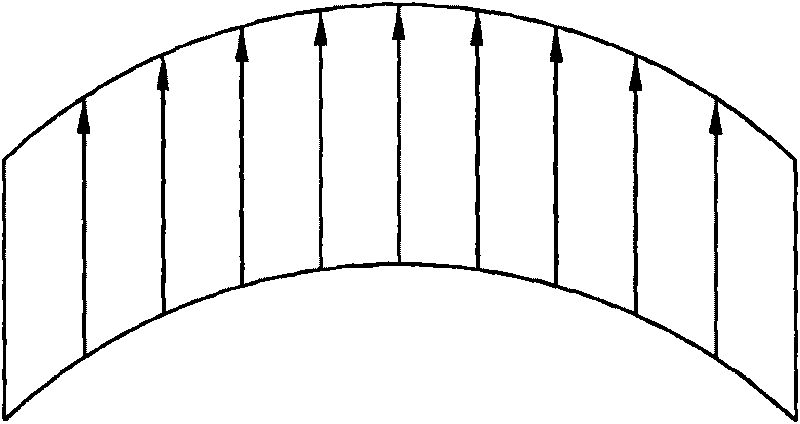

[0015] The permanent magnet DC motor stator magnetic tile molding die, such as image 3 Shown, comprise upper template 1, upper die head, magnetic tile mold cavity 3, lower die head, mold cover 5 and lower template 6, upper die head is fixed on the upper template 1, the curved surface of the lower end surface of upper die head and magnetic The outer arc surface of the tile is the same, and the upper die head is composed of a bias magnetic insert 21 and an upper module 22, and the bias magnetic insert 21 is embedded in the center of the upper module 22. The bias magnetic insert 21 is trapezoidal, and the bottom of the trapezoid is Arc-shaped, its arc length is 1 / 4 to 2 / 3 of the outer arc length of the magnetic tile, the bias magnetic insert 21 is a non-magnetic material, the upper module 22 is a magnetic material; the lower die head is composed of a hyperbolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com