A power line deicing device

A transmission line and pair technology, applied in the field of transmission line maintenance devices, can solve the problems of energy consumption, system safety impact, high cost, etc., and achieve the effects of low deicing cost, good safety performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

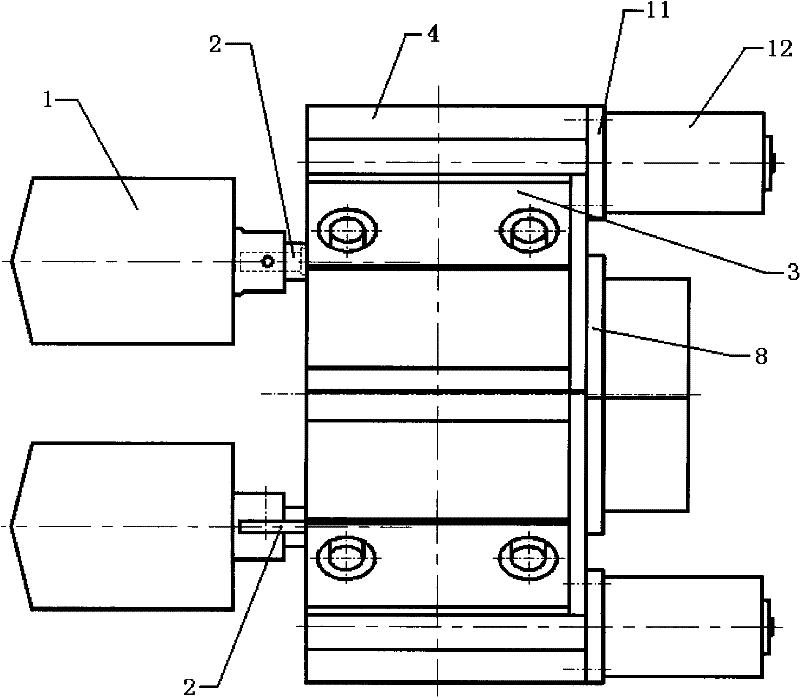

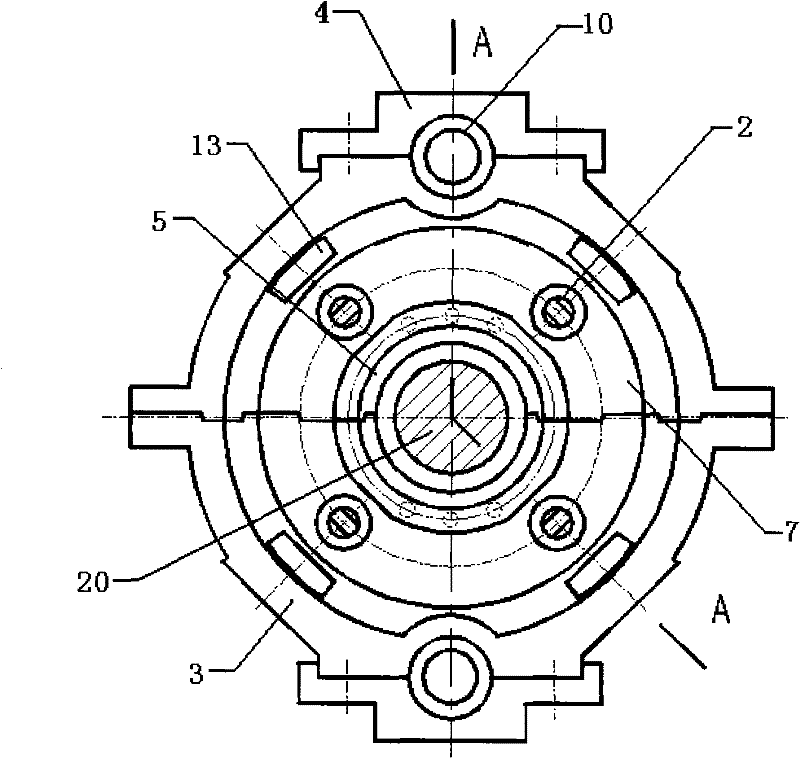

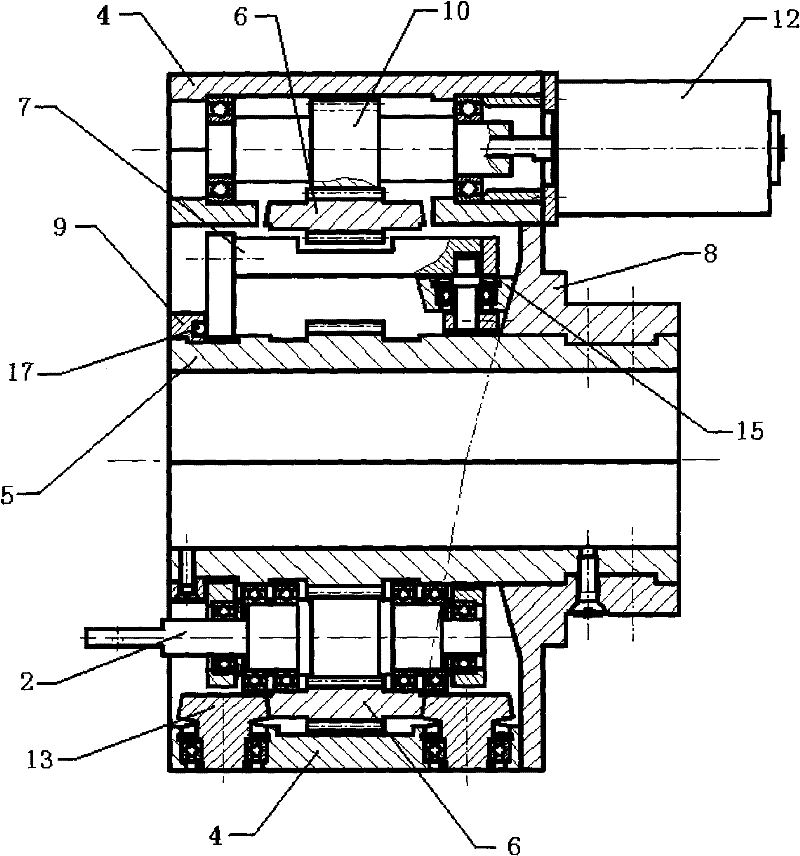

[0022] Figure 1. Milling cutter. 2. Planetary gear shaft. 3. Shell. 4. Shell cover. 5. Sun wheel. 6. External gear. 7. Cage. 8. Back cover. 9. Baffle. 10. Motor gear shaft. 11. Cover plate. 12. Drive motor. 13. External gear roller. 15. Cage rollers. 16. Locating pins. 17 balls. 18 connection plates. 19 Robots walking along transmission lines. 20. Power lines.

[0023] combine Figure 1~1 0 The present invention will be further described below in conjunction with embodiment.

[0024] The present invention relates to a power transmission line maintenance device, especially a power transmission line deicing device, which includes a sun gear 5 fastened on the power transmission line 20, a casing 3 arranged outside the sun gear 5 and having an "O"-shaped inner wall, The cage 7 arranged along the circumference of the outer wall of the sun gear 5, the casing cover 4 connected to the top and bottom of the casing 3, the driving motor 12 and the reducer are characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com