Method for manufacturing flash memories

A technology of flash memory and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of reducing the off-current and increasing the resistance of the device, and achieves the advantages of reducing the off-current, increasing the distance, and increasing the width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

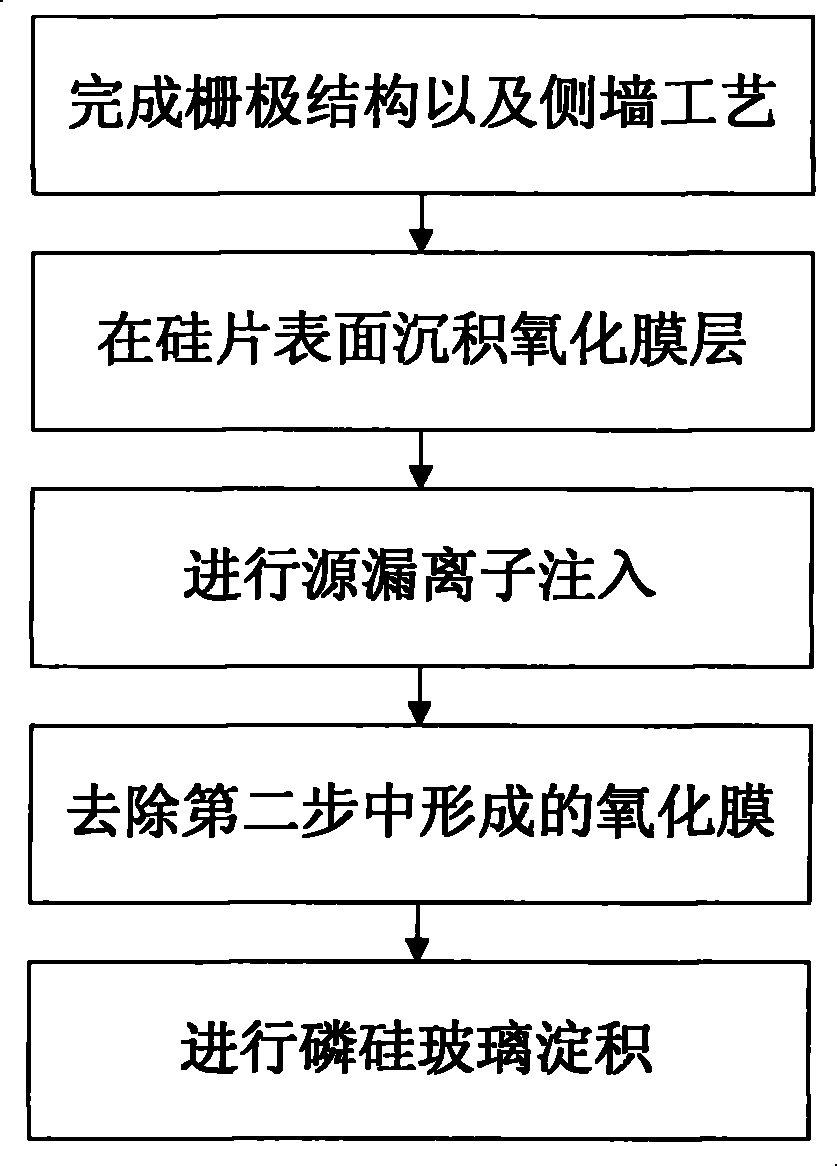

[0030] Such as Figure 9 As shown, the flash memory preparation process of the present invention includes the following steps:,

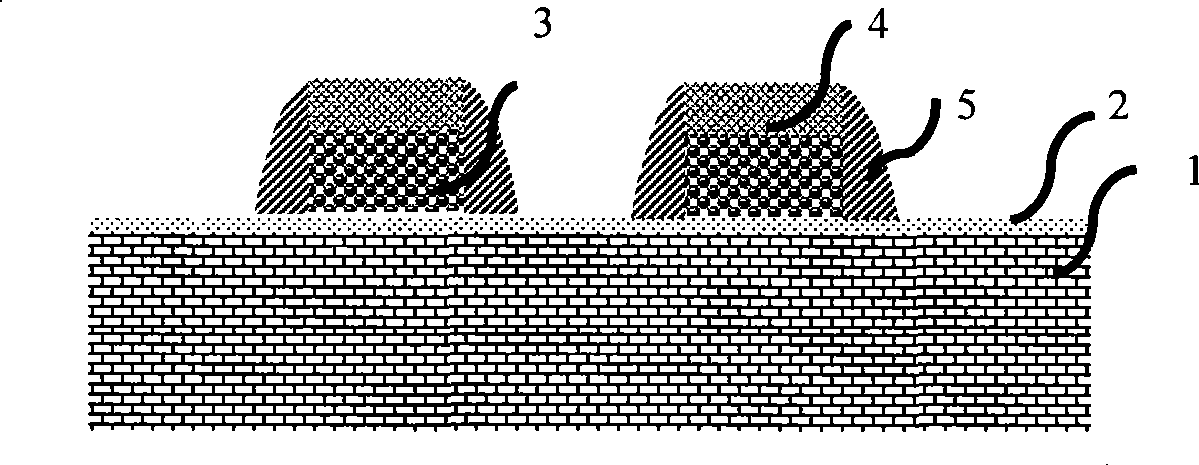

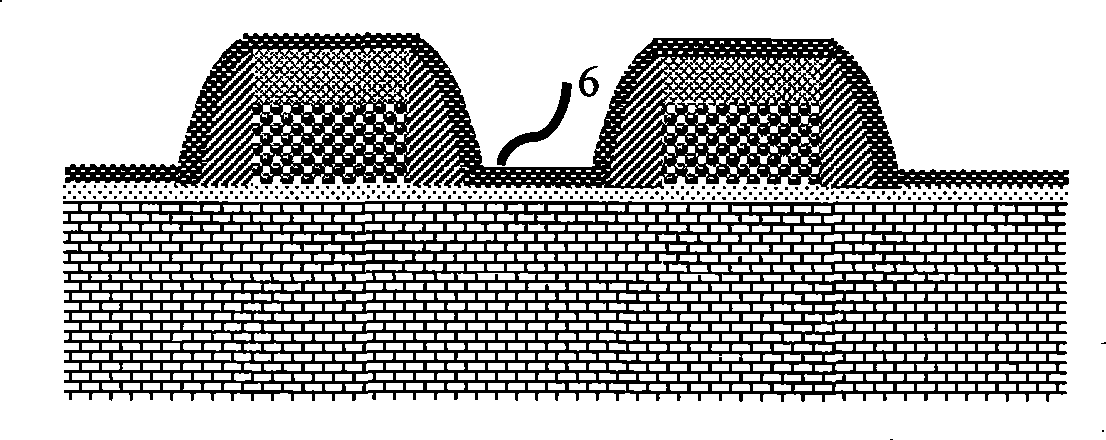

[0031] Firstly, a polysilicon gate is formed using a conventional process and the sidewall is etched. Its structure is as follows: Figure 10 As shown, there is a gate oxide layer 2 on a silicon substrate 1, a polysilicon gate 3 is grown on the gate oxide layer, and a hard mask layer 4 is formed on the polysilicon gate. ) and etching process to form a traditional spacer 5 on the side of the polysilicon gate structure. Then, if Figure 11 As shown, an oxide film 6 is deposited on the surface of the silicon wafer. The oxide film of this layer can increase the distance from the gate to the source and drain, and at the same time play the role of the source and drain injection sacrificial oxide layer.

[0032] Next, if Figure 12 As shown, a layer of nitride film dielectric 9 is deposited. Then, if Figure 13 As shown, the nitride film dielectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com