Method for dyeing interface of bursting body

A dyeing method and interface technology, applied in blasting, ground mining, earthwork drilling and mining, etc., can solve problems such as indirect comparison, and achieve the effect of easy verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

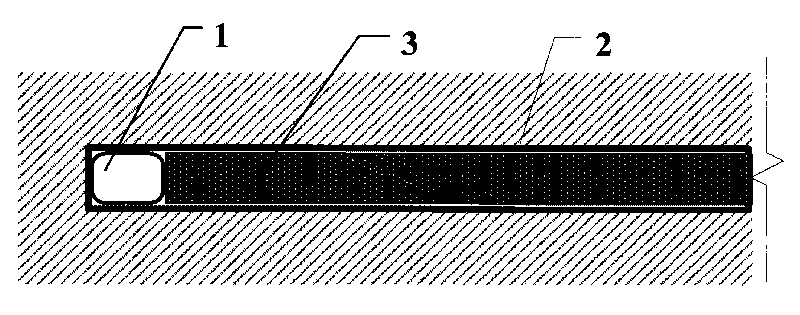

[0012] Such as figure 2 shown. In the caving mining method, a dye pack 1 is placed at the bottom of the blast hole 2 at the top of the ore body to form a dyeing interface for blasting ore at the top.

Embodiment 2

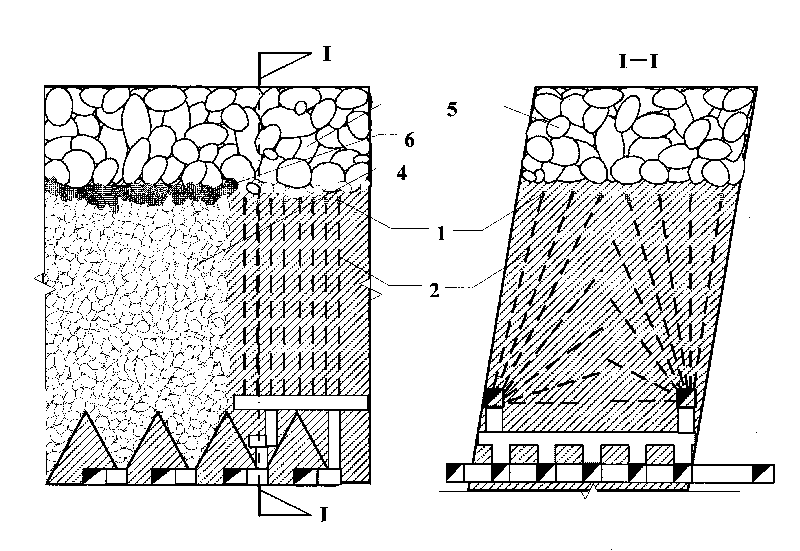

[0014] When adopting the caving method to mine a blind ore body with stable surrounding rocks, it is necessary to use forced caving to form a cushion layer of waste rock 5 . Generally, fan-shaped medium-deep hole blasting is used in the surrounding rock before the mine collapses. At this time, the dye package can be placed in the position close to the hole in the caving blast hole or in the lower horizontal blast hole 2 near the caving rock mass. After blasting, these dyed ores or rocks can be blasted ore 4 The dyed interface 6 of the loose body forms a specific interface sign of the exploded body, and provides information on the rocks that first arrive at the ore-drawing mouth for subsequent ore-drawing operations.

Embodiment 3

[0016] In mining production blasting (not limited to caving mining method), different color dye packs can be set in appropriate positions in the blasting boundary blastholes of different blasting units. Provide direct evidence. For example, whether it is underexcavated or overexcavated, the situation of large blocks formed by non-blasting factors, etc. It can enrich the information of blasting effect observation and statistics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com