Embossing bicolor leather

A two-color leather and embossing technology, which is applied in the field of embossed two-color leather, can solve the problems of weak three-dimensional effect, inconspicuous two-color effect and poor discoloration effect of PU two-color leather, and achieve obvious two-color effect, strong two-color and discoloration effect, Strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

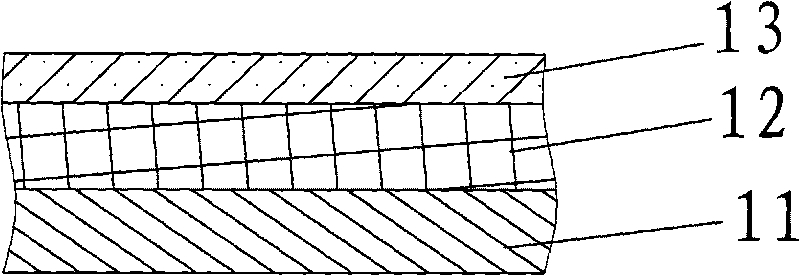

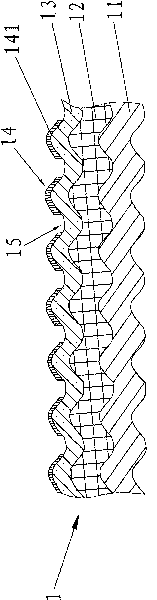

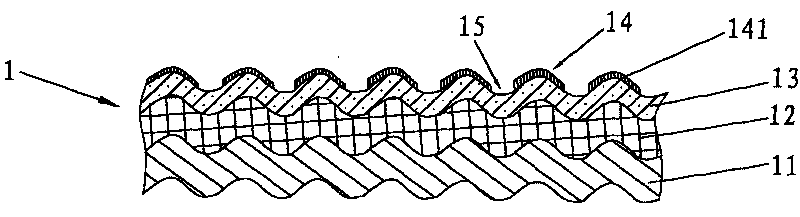

[0021] Such as figure 1 As shown, the two-color leather of the present invention comprises a base cloth layer 11, a polyurethane foam layer 12 coated on the base cloth layer 11, a crazy horse resin discoloration layer 13 coated on the polyurethane foam layer 12, and after the crazy horse is coated After resin discoloration layer 13, carry out embossing treatment to the obtained synthetic leather, make leather surface uneven, as figure 2 As shown, a plurality of crowns 14 and a plurality of grooves 15 are formed on the leather surface, and a layer of roller coating 141 is coated on the surface of the crowns 14 .

[0022] The roller coating 141 uses a moisture-cured resin layer to make the crown have a bright and transparent crystal feeling, and the synthetic leather has a stronger three-dimensional effect; or a resin layer with a different color from the color-changing layer of Crazy Horse resin can be used, and the two-color effect is more obvious.

[0023] The base cloth la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com