Gas injector and film deposition apparatus

An injection device and gas injection technology, which is applied in the direction of injection devices, injection devices, electrical components, etc., can solve the problems of long processing time, reaction product adhesion, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

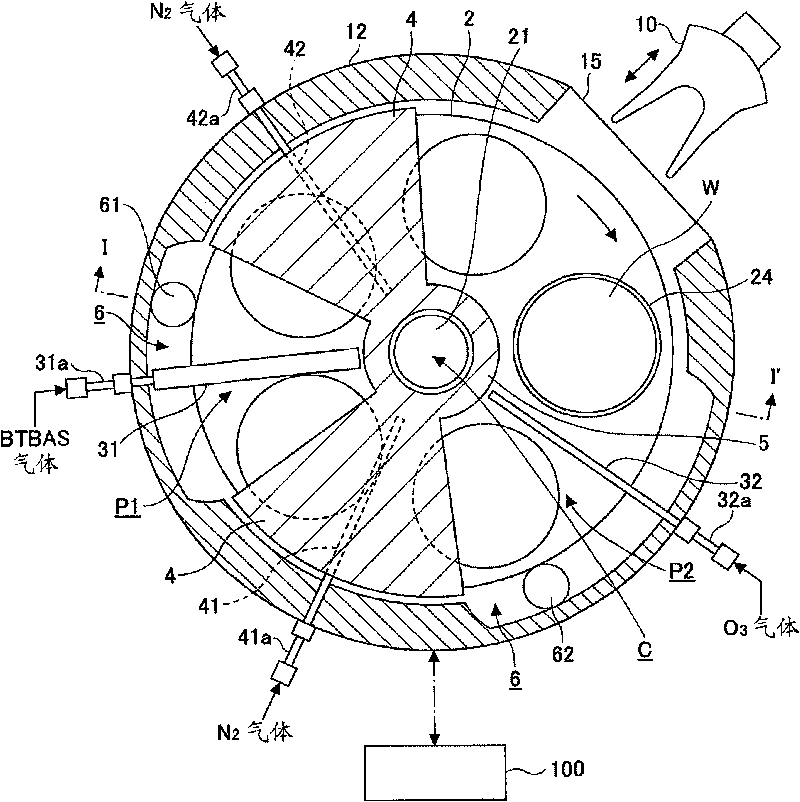

[0121] As the first reactant gas supply unit, a Figure 8 ~ Figure 1 The concentration distribution of the BTBAS gas directly under the gas injection device 31 was simulated using the gas injection device 31 having the same structure as the gas injection device shown in the embodiment of 0. Figure 20A A longitudinal sectional side view of the gas injection device 31 used in the simulation is schematically shown. In addition, the design conditions of the gas injection device 31 are as follows.

[0122] Diameter of gas outflow hole 313: 0.5mm

[0123]Spacing between centers of gas outflow holes 313: 5.0mm

[0124] The number of arranged gas outflow holes 313: 67

[0125] Slit width of gas ejection port 316: 0.3 mm

[0126] Height H1 from the upper surface of the turntable 2 (wafer W surface) to the gas ejection port 316: 4mm

Embodiment 2

[0128] As the first reactant gas supply unit, a Figure 12 , Figure 13 The gas injection device 31a having the same structure as the gas injection device shown in another embodiment of the present invention simulated the concentration distribution of the BTBAS gas directly below the gas injection device 31a. Figure 20B A longitudinal sectional side view schematically shows a gas injection device 31a used in the simulation. In addition, the design conditions of the gas injection device 31a are as follows.

[0129] Diameter of gas outflow hole 313: 0.5mm

[0130] Interval between centers of gas outflow holes 313: 10 mm

[0131] The number of arranged gas outflow holes 313: 32

[0132] The slit width of the gas ejection port 316: 2.0mm

[0133] Height H1 from the upper surface of the turntable 2 (wafer W surface) to the gas ejection port 316: 4mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com