Closed type portal high-speed punch press stand

A high-speed punch and frame technology, which is applied in the direction of presses, mechanical equipment, engine components, etc., can solve the problems of lubricating oil return, difficult installation of crankshaft pads, and high processing costs, to improve accuracy, reduce difficulty and process. cost, the effect of avoiding oil leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

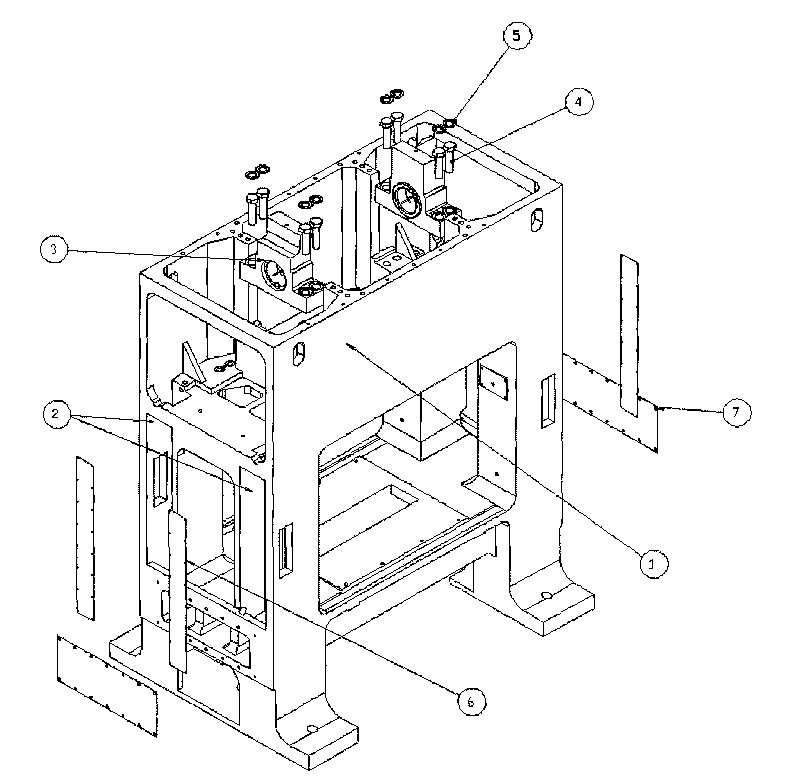

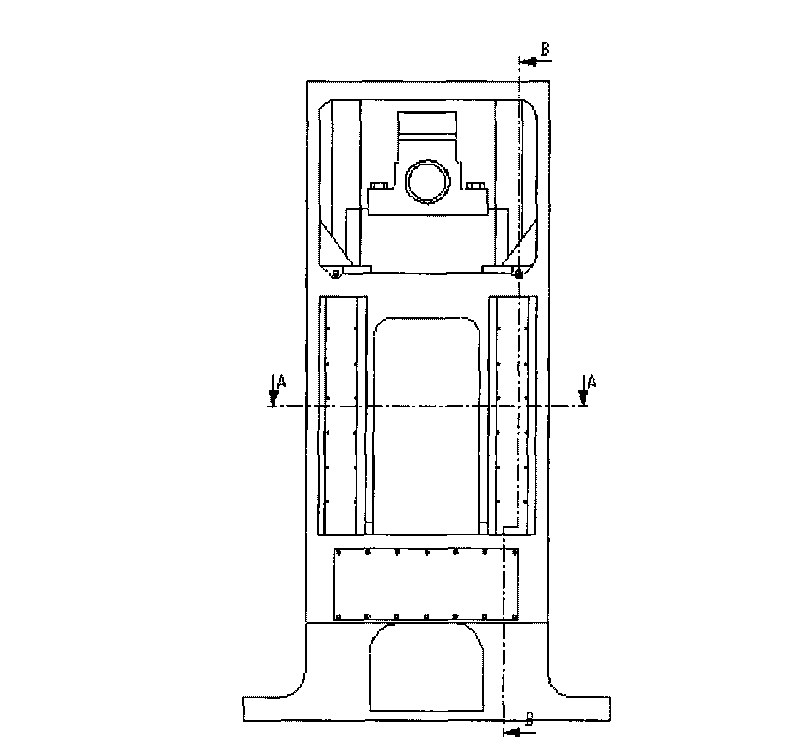

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a closed-type gantry high-speed punching machine frame includes an upper body 1 as the main working part, a lubricating oil passage 2, an oil tank 8, a crankshaft seat 3, bolts 4 and a hard thickened flat washer 5. The bottom of the crankshaft seat 3 is a plane, positioned on the corresponding plane in the platform body 1, and fixed by the bolt 4 and the hard thickened flat washer 5. The lubricating oil channel 2 is distributed on the inner wall around the punch frame, and the upper part is connected to the inner wall of the punch frame. The top tank 9 communicates, and the bottom communicates with the fuel tank 8 .

[0023] Bore channels 10 are provided on both sides of the bottom of the top box 9 , connecting the top box 9 and the lubricating oil passage 2 .

[0024] The lubricating oil from each lubricating point of the crankshaft flows to the top box, flows to the lubricating oil passage 2 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com