Method of setting mold clamping force of injection molding machine

一种注射成型机、设定方法的技术,应用在合模力设定领域,能够解决无法用、无法得到模具变形、增大余量等问题,达到容易自动化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

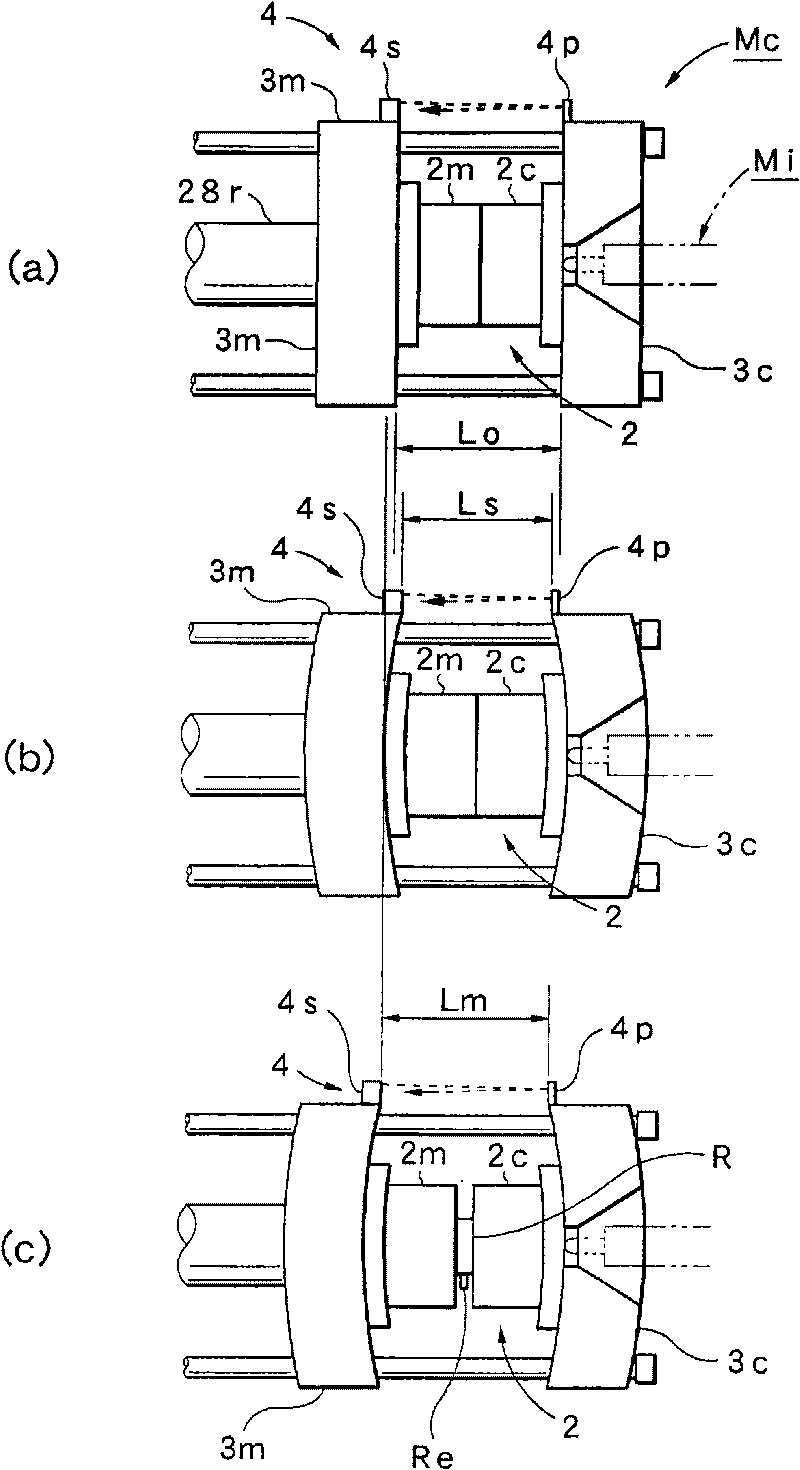

[0029] Hereinafter, a preferred embodiment of the present invention will be taken as an example to describe in detail according to the accompanying drawings. In addition, the purpose of the accompanying drawings is to facilitate understanding of the present invention, not to limit the present invention. In addition, in order not to obscure the invention, detailed descriptions of known parts are omitted.

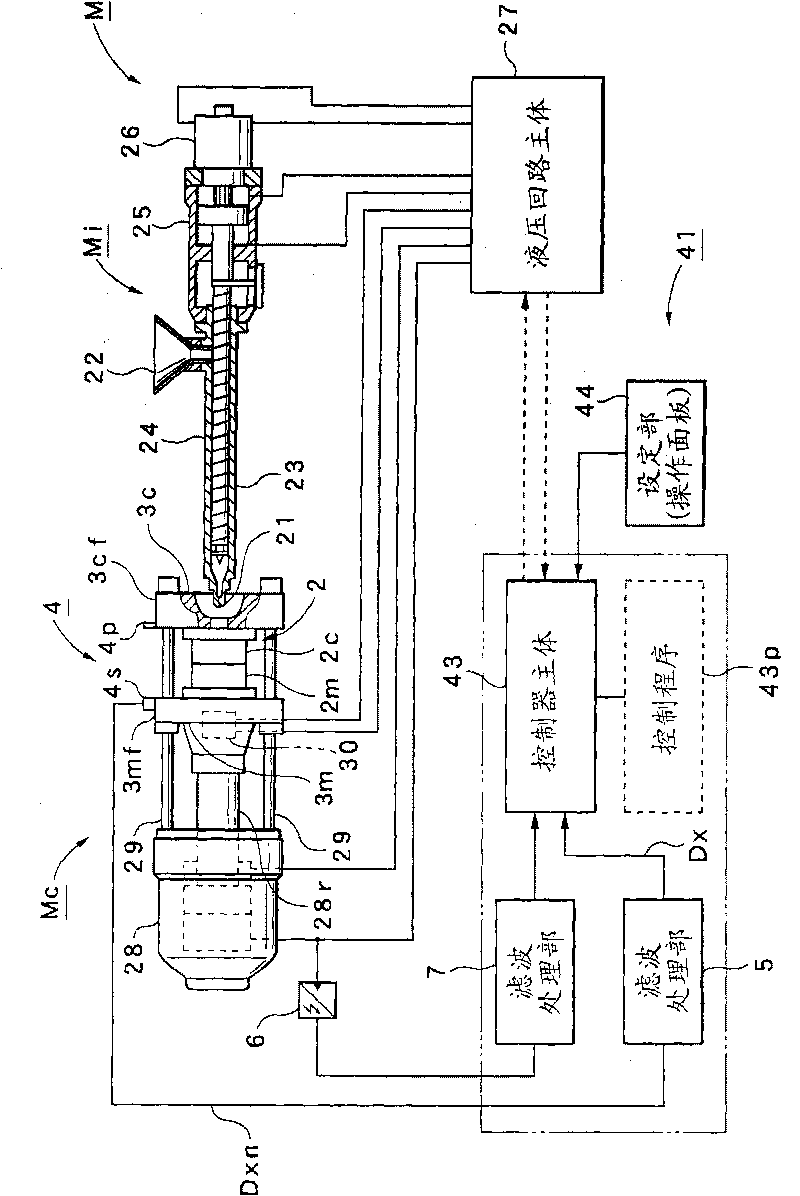

[0030] First, refer to figure 1 and figure 2 The configuration of the injection molding machine M capable of implementing the mold clamping force setting method of this embodiment will be described.

[0031] exist figure 2Among them, M is an injection molding machine, which has an injection device Mi and a mold clamping device Mc. The injection device Mi has a heating cylinder 23 having an injection nozzle 21 at the front end and a hopper 22 for material supply at the rear, and a screw 24 is built in the heating cylinder 23 . In addition, an injection cylinder (cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com