Method for preparing film type biological adsorbing medium

A biosorption, medium technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of limited bacterial application, inability to meet requirements, and insufficient repeated batches, etc. Adsorption capacity, low cost, effect of increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Grind 10g of monosodium glutamate waste mycelia, the particle size is 2 On the ceramic membrane, the surface is covered with a ceramic membrane of the same size. After compaction, the adsorbent is solidified in 0.005M NaOH solution for 12 hours, and washed with water until neutral. Dry at 30°C to obtain a membrane biosorption medium. Take 0.15g membrane biosorption medium and 50ml Cu(SO 4 ) 2 Aqueous solution, join in the Erlenmeyer flask of 150ml, at room temperature, after rotating speed 150dyn / m shakes 24 hours (adsorption balance), measure the metal ion Cu in the solution 2+ The adsorption capacity is 108mg / g. The experimental results show that the adsorbent can be used in a wide range of pH = 2 to 13; desorb with 0.05M sulfuric acid 50ml for 3h, wash with water until neutral; then regenerate with 0.005M NaOH 200ml for 12h, rinse with water until neutral ,dry. In Cu 2+ When the concentration is 400mg / L, the adsorption capacity is still not significantly reduced...

Embodiment 2

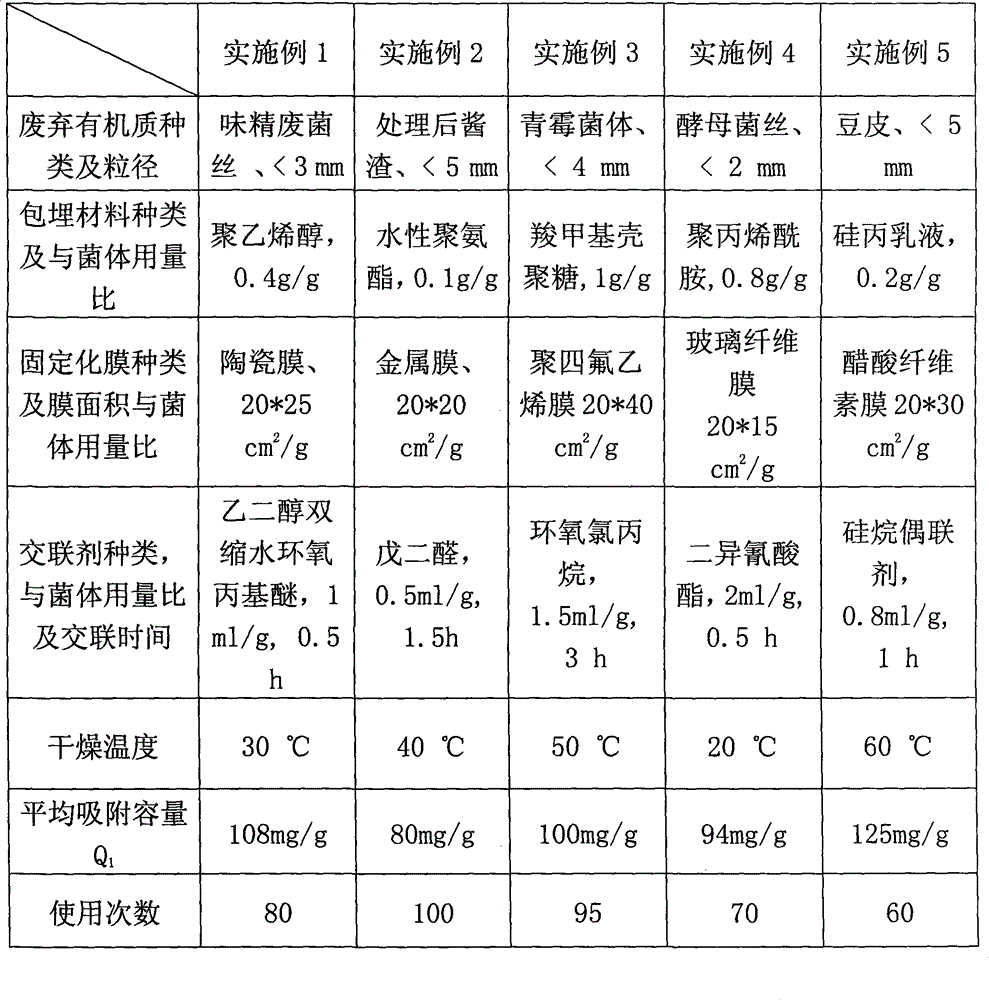

[0029] The operating methods of embodiment 2, embodiment 3, embodiment 4 and embodiment 5 are the same as embodiment 1, and the operating parameters are shown in table 1.

Embodiment 5

[0031] Crush 10g of bean curd with a particle size of 2 On the cellulose acetate film, the surface is covered with cellulose acetate film of the same size. After compaction, the adsorbent is solidified in 0.25M NaOH solution for 3 hours, and washed with water until neutral. Dry at 30°C to obtain a membrane biosorption medium. Take 0.15g membrane biosorption medium and 50ml Cu(S0 4 ) 2 Aqueous solution, join in the Erlenmeyer flask of 150ml, at room temperature, after rotating speed 150dyn / m shakes 24 hours (adsorption balance), measure the metal ion Cu in the solution 2+ The adsorption capacity is 125mg / g. The experimental results show that the adsorbent can be used in a wide range of pH = 2 to 13; then desorb with 10ml of 0.8M citric acid for 8h, wash with water until neutral; then use 1M NaCO 3 20ml regeneration 8h, rinse with water to neutral, dry. In Cu 2+ When the concentration is 400mg / L, the adsorption capacity is still not significantly reduced after repeated use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com