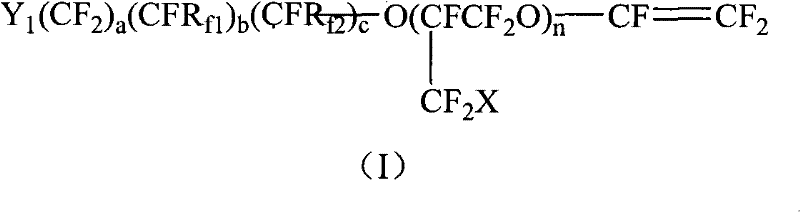

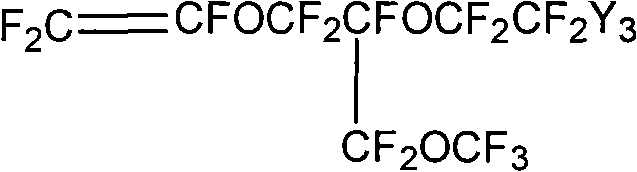

Enhanced multi-layer fluorine-containing ion exchange membrane

A technology of ion-exchange membrane and ion-exchange resin, applied in collectors/separators, electrical components, circuits, etc., can solve the problems of reduced membrane strength, decreased perfluoropolymer equivalent value, and low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Placing PTFE fibers in SiCl 4 After 1 hour in the atmosphere, the temperature was raised to 110° C., and kept for 1 hour. After cooling to 60° C., water spray treatment was performed to obtain silica-modified polytetrafluoroethylene fibers.

Embodiment 2

[0070] Placing E-glass fibers in Ti(OEt) 4 In the water mixing system, concentrated ammonia water is added under stirring, hydrolyzed and left to stand to obtain the alkali-free glass fiber modified by titanium dioxide.

Embodiment 3

[0072] Triethyl phosphate and tetraethyl orthosilicate (1:100 mass ratio) were mixed, water and concentrated ammonia were added and the gel was allowed to stand for 12 hours, and then the gel was used electrospinning or spinning technology to obtain phosphoric acid-modified diethyl ether. Silica fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com