Method for predicting periodic porous material equivalent shear modulus

A technology of shear modulus and porous materials, which is applied in the direction of testing the strength of materials by applying a stable shear force, and can solve the problem of predicting the equivalent shear modulus of materials that cannot reflect changes in cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Equivalent shear modulus of rectangular hole unit cell.

[0025] 1) Establish a periodic rectangular hole porous cylinder structure, the parameters of which are the length of the cylinder L=240, the outer diameter of the cylinder R=40, and the inner diameter r=20. The period of a single rectangular hole cylinder microstructure unit cell in the circumferential direction is The volume ratio of the rectangular hole is υ=0.4, and the span of the rectangular hole in the circumferential direction is φ=π / 6. The physical material properties are: Young's modulus E=70e9, Poisson's ratio v=0.34, shear modulus G=2.6119e10, density ρ=2774; set the scale scaling factor n=1 at this time.

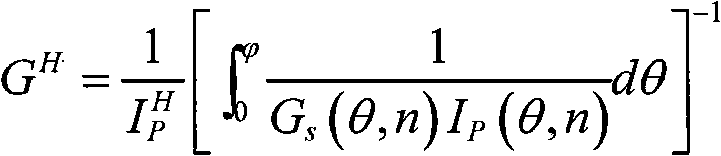

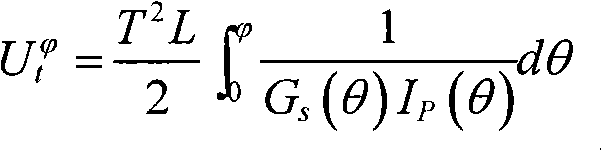

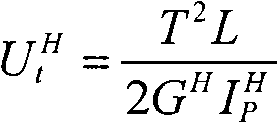

[0026] 2) Perform torsion loading on the periodic rectangular hole porous cylindrical structure, according to the periodicity of the structure along the circumferential direction, a single cycle Bending strain energy for:

[0027]

[0028] Where G s (θ)=G, I P (θ) is

[0029] I p ( ...

Embodiment 2

[0049] Example 2: Equivalent shear modulus of round hole unit cell.

[0050] 1) Establish a periodic circular hole porous cylinder structure, the parameters of which are the length of the cylinder L=240, the outer diameter of the cylinder R=40, and the inner diameter r=20. Period is The volume ratio of the circular hole is υ=0.25. The physical material properties are: Young's modulus E=70e9, Poisson's ratio v=0.34, shear modulus G=2.6119e10, density ρ=2774; set the scale scaling factor n=1 at this time.

[0051] 2) Perform torsion loading on the periodic circular hole porous cylindrical structure, according to the periodicity of the structure along the circumferential direction, a single period Bending strain energy for:

[0052]

[0053] Where G s (θ)=G, I P (θ) is

[0054] I P ( θ ) = π 2 ( R 4 - r 4 ) - 8 [ π 2 ( r cm ) 4 + π ( r cm ) 4 ( R + r 2 ) 2 ]

[0055] ...

Embodiment 3

[0073] Example 3: The equivalent shear modulus of the triangular support unit cell.

[0074] 1) Establish a periodic triangular supporting cylinder structure, the parameters of which are the length of the cylinder L=240, the outer diameter of the cylinder R=40, and the inner diameter r=20. The period of a single triangular supporting cylinder microstructure unit cell in the circumferential direction is The thickness of the outer wall of the triangular support cylinder microstructure unit cell is t o =4, the wall thickness of the sandwich layer is t c =4, the inner wall thickness is t i = 4. The physical material properties are: Young's modulus E=70e9, Poisson's ratio v=0.34, shear modulus G=2.6119e10, density ρ=2774; set the scale scaling factor n=1 at this time.

[0075] 2) Perform torsion loading on the periodic triangular support cylinder structure, according to the periodicity of the structure along the circumferential direction, a single cycle Bending strain energy for:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com