External taper measuring apparatus

A measuring instrument, the technology of external taper, applied in the direction of angle/taper measurement, etc., can solve the problems of unadjustable relative relationship, on-site measurement deviation, low measurement accuracy, etc., achieve good neutrality, reduce measurement error, and ensure measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

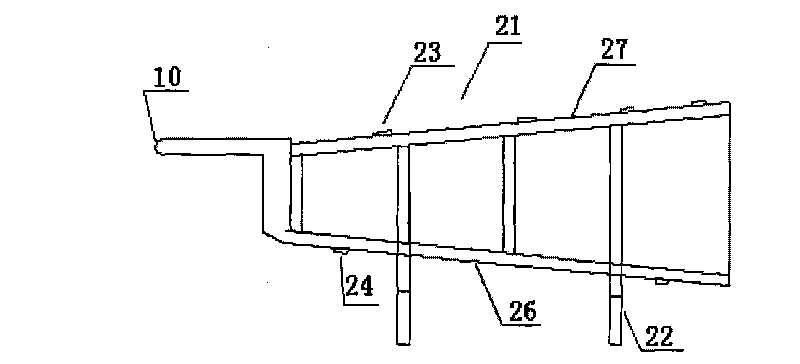

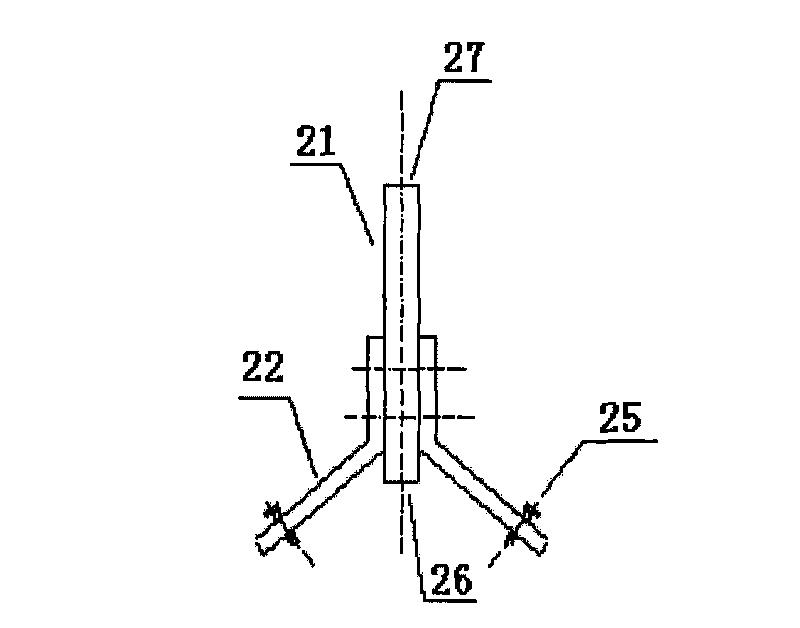

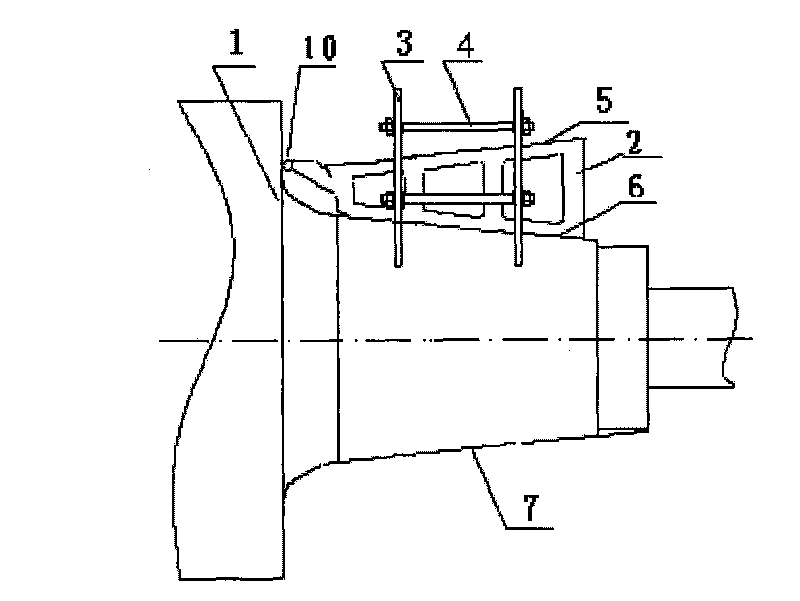

[0031] image 3Shown is an external taper measuring instrument, which includes a bracket and an isosceles trapezoidal measuring plate 2 with a rounded fulcrum 10 . The roughness of the round fulcrum 10 is Ra0.8.

[0032] The measuring plate 2 is made of T8 steel quenching and aging treatment material, the upper waist of the isosceles trapezoid is the measuring surface 5, and the lower waist is the reference plane 6, and the two waists are processed simultaneously through grinding. After assembly, the perpendicularity between the measuring plate and the workpiece is 0.06-0.08mm, the flatness of the reference plane and the measuring surface of the measuring plate must be guaranteed to be 0.015mm, the roughness is Ra0.8, and the perpendicularity is 0.02mm.

[0033] The bracket includes two identical vertical support plates 3 processed and formed at the same time. The outer contour of the radial structure of the vertical support plates 3 is formed by two inverted V-shaped upper n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com