Middle-bent axial flow fan blade

An axial flow fan and blade technology, applied in the field of blade bending structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

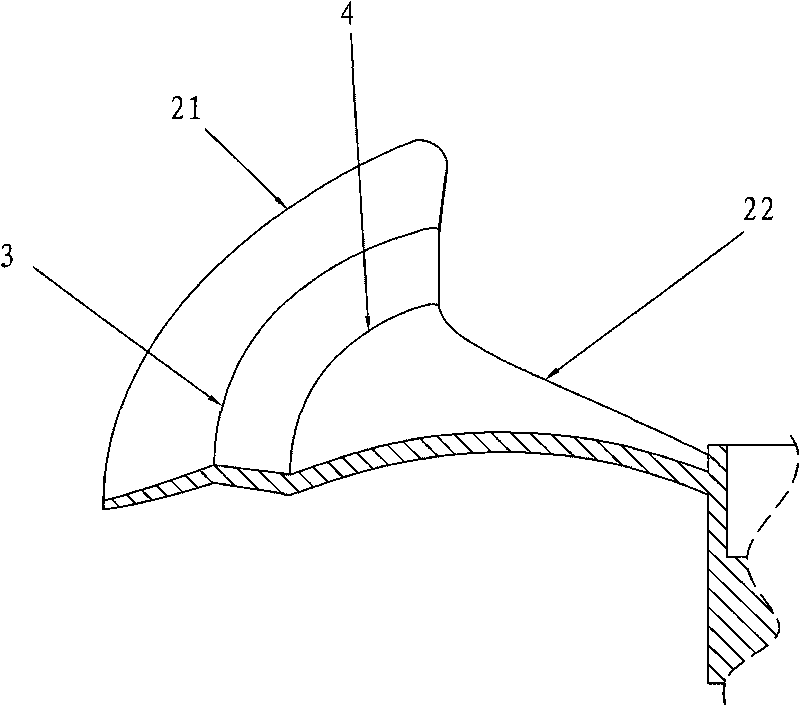

[0015] Such as figure 1 , figure 2 As shown, an axial flow fan blade with a bent middle part of the blade includes a hub 1 and a blade 2. The blade 2 includes an outer circumference 21, a leading edge 22 and a trailing edge 23. The blades 2 are arranged in the radial direction, A continuous crest 3, trough 4 undulation from the leading edge to the trailing edge.

[0016] The peaks 3 and troughs 4 are within the range from the vane located close to 80% of the outer circumference to the 95% of the outer circumference.

[0017] The bending width of the crest 3 or trough 4 is 10%D≤B≥5%D. D is the diameter of the wind wheel; B is the width of the bend.

[0018] The tops of the peaks 3 and the bottoms of the troughs 4 are obtuse angles.

[0019] The tops of the crests and the bottoms of the troughs may also have rounded corners.

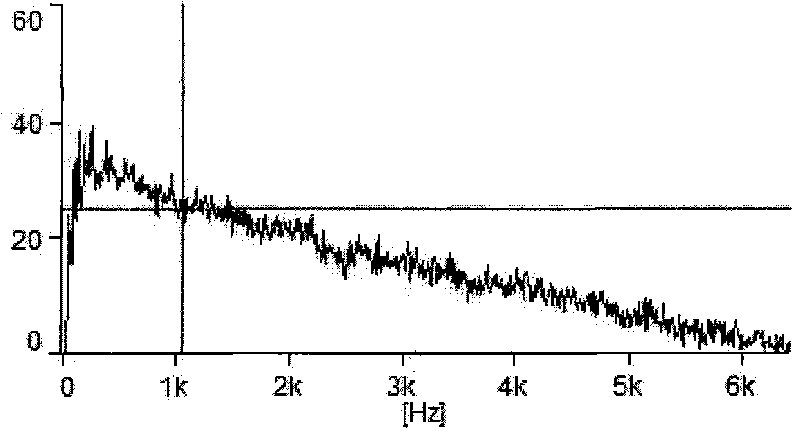

[0020] Under the same conditions, to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com