New-principle super energy-saving engine

An engine, super energy-saving technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve problems such as large vibration, and achieve the effect of large proportion of energy and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

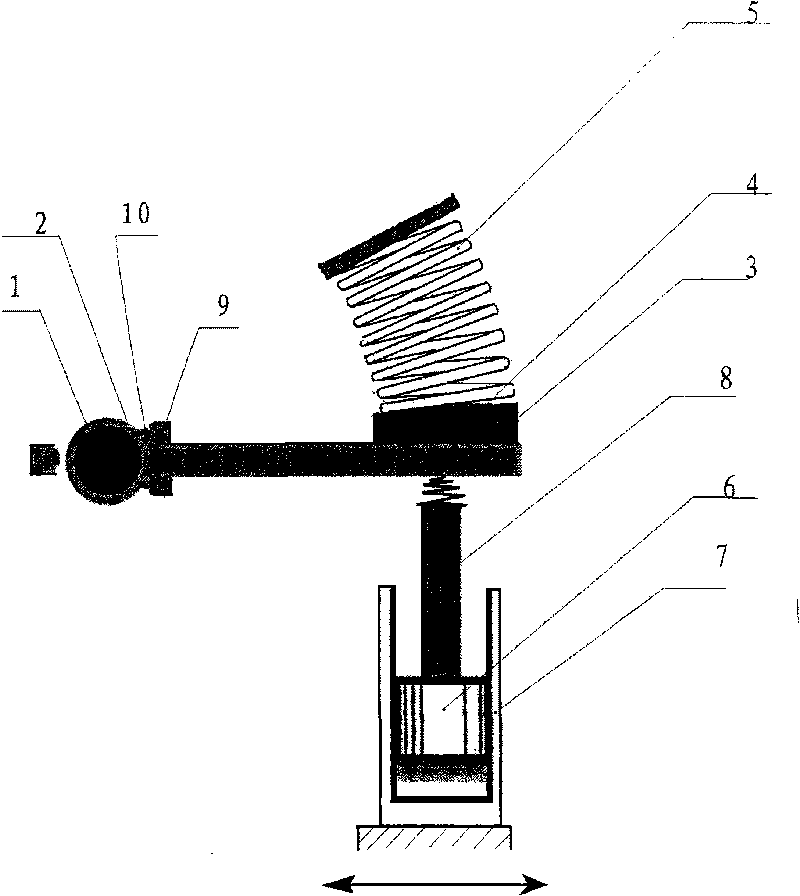

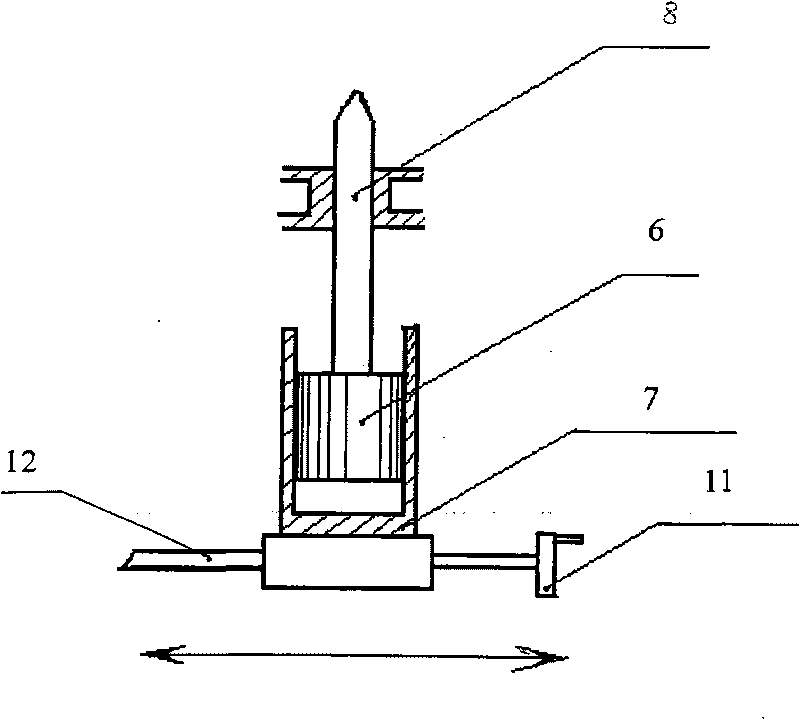

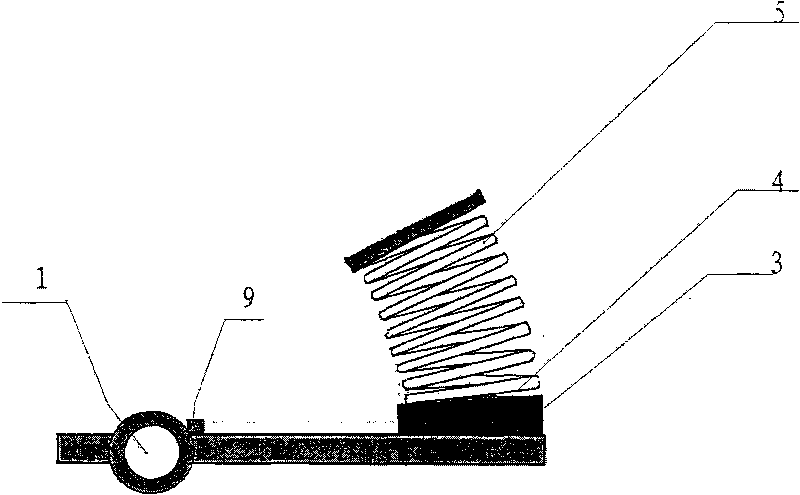

[0029] Motor of the present invention is mainly lever structure and spur tooth structure. The piston of the cylinder part is directly connected to the top (8). The straight tooth structure is that the piston is connected to the top, and there is a buffer spring on the top. The spring is aligned with the center of the inertia hammer. The straight teeth are installed on the inertia hammer. The extension direction should be consistent with the direction of the piston movement, and it should be able to well promote the rotation of the one-way gear. The straight teeth are directly meshed with the one-way wheel; the piston of the lever structure is connected to the top, and there is a buffer spring on the top. lever. Through mechanical or electronic control, the output of the cylinder part is the same or similar to the natural frequency of the resonant part, and the rhythmic and periodic impact force acts on the lever or inertial hammer, so that the pendulum of the resonant part (3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com