Feeding device of pouring pile underwater concrete and pouring method thereof

A technology of underwater concrete and pouring method, which is applied in the direction of construction and infrastructure engineering, etc., can solve the problem of limited reduction of resistance pressure, achieve the effect of increasing active pressure, significant economic and comprehensive benefits, and accelerated pouring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

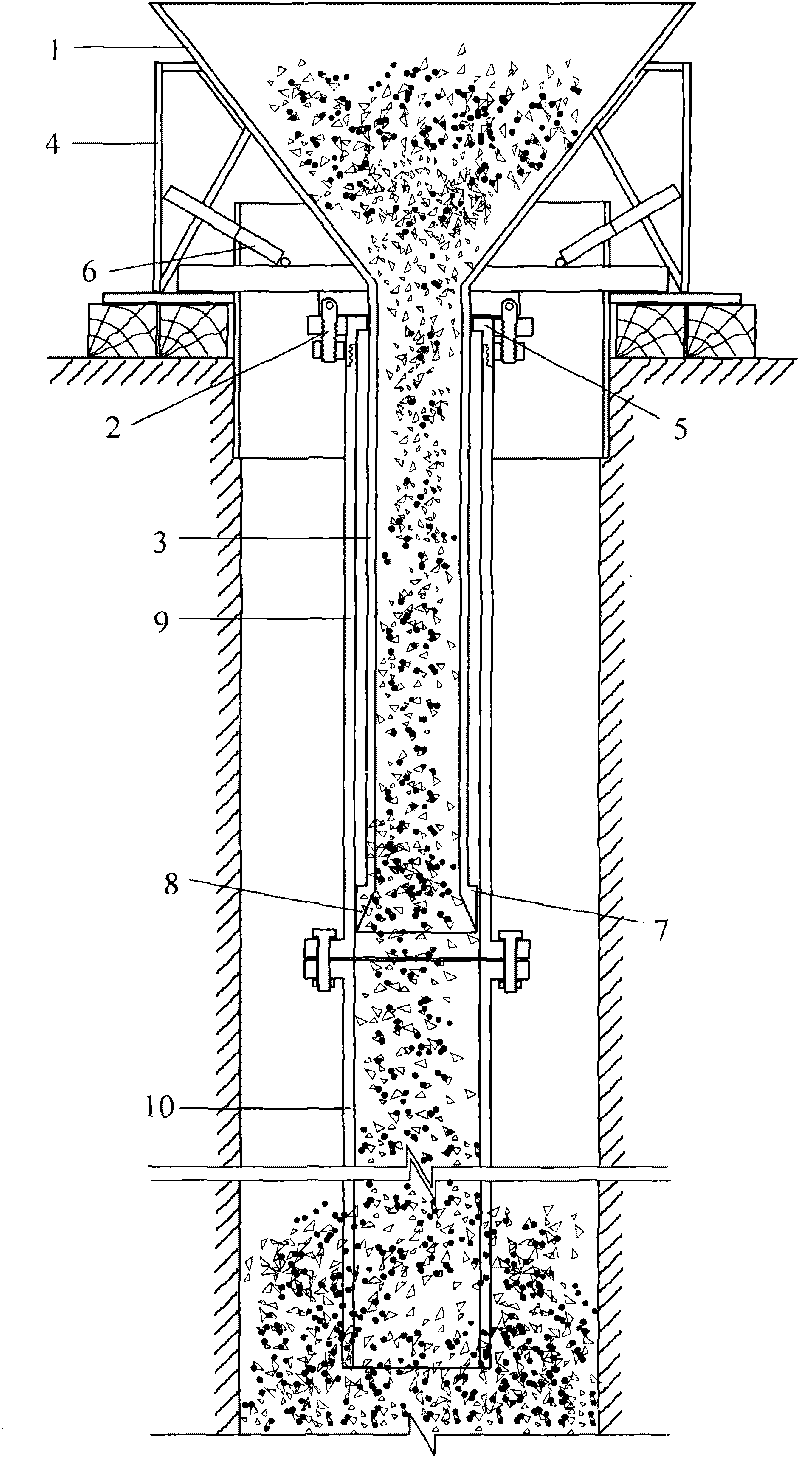

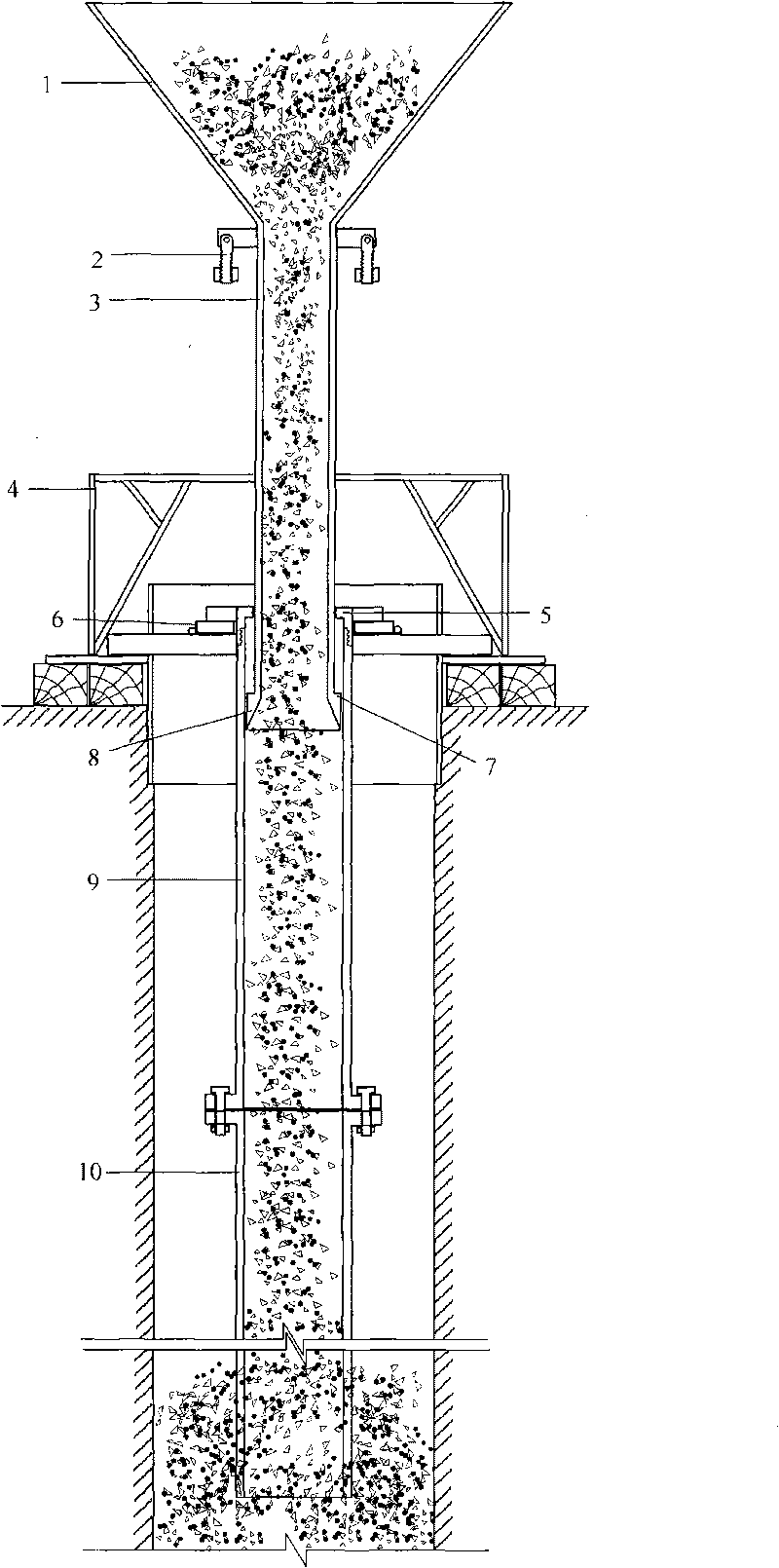

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Depend on Figure 1-9 It can be seen that, at the pile hole after the hole is formed, install the hopper frame 4 and the card cover 6, open the card cover 6, and then connect the circular conduit 10 joint by joint, pass the card cover 6, and go down into the pile hole from the bottom of the hole. At the position of 300mm-500mm, the top of the circular conduit 10 is connected to the flange at the lower end of the casing 9, and then the hopper 1 is placed on the hopper frame 4, and the hopper 1 is connected to the casing 9 by tightening the bolt 2; 11 Plug the feed inlet at the bottom of hopper 1, and fill the hopper 1 with an appropriate amount of concrete according to the pre-calculated results [the amount of filling shall not be less than: 3.14×radius of cast-in-place pile 2 ×(the distance between the bottom end of the conduit and the bottom of the hole+0.8m)]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com