Hydrogenation combined method for diesel oil

A combined method and diesel oil technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems that the quality of distillate oil cannot meet the product quality requirements, the density of catalytic cracking diesel oil is high, and the content of aromatic hydrocarbons is high, so as to save equipment , improve service life and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

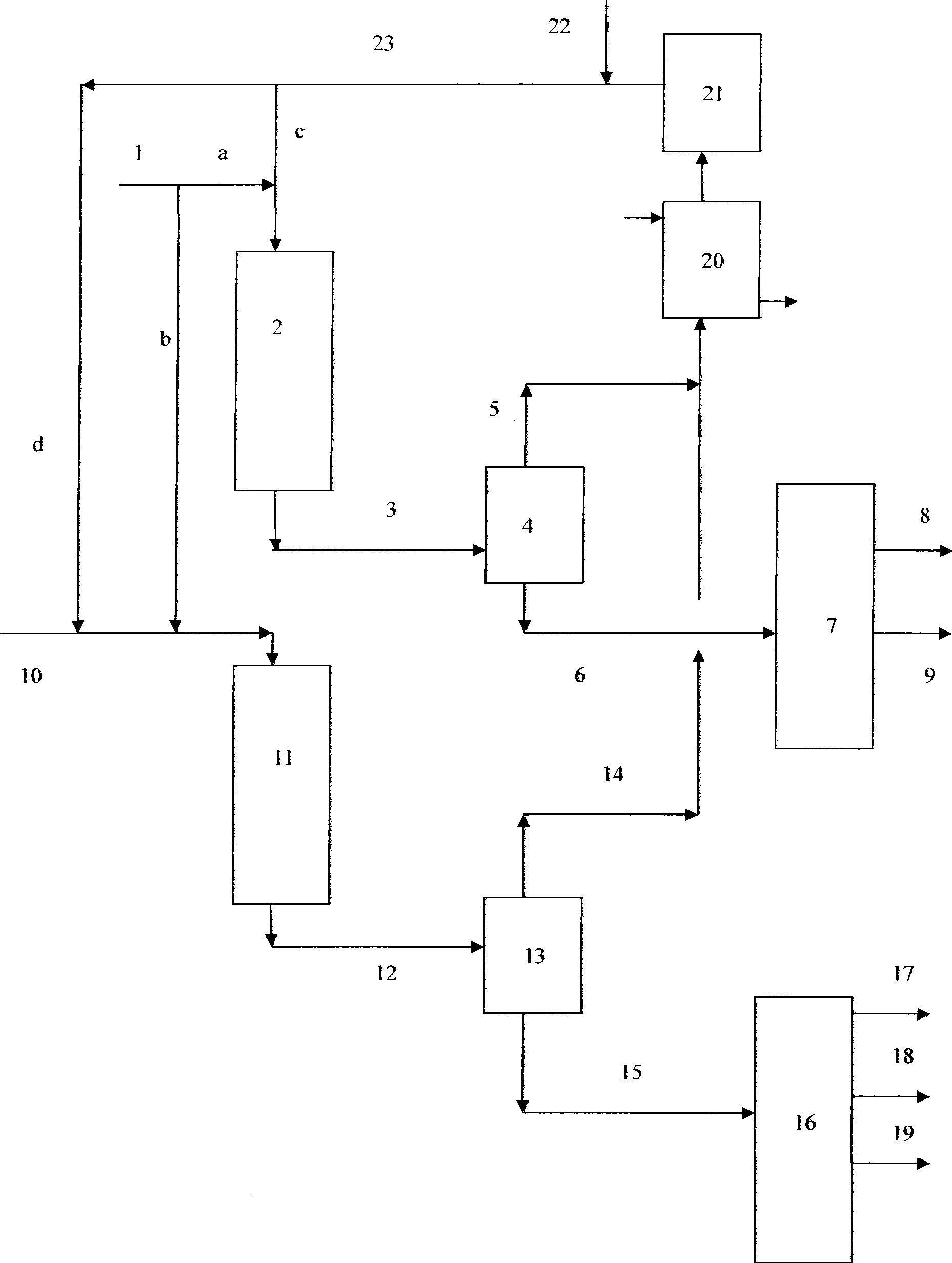

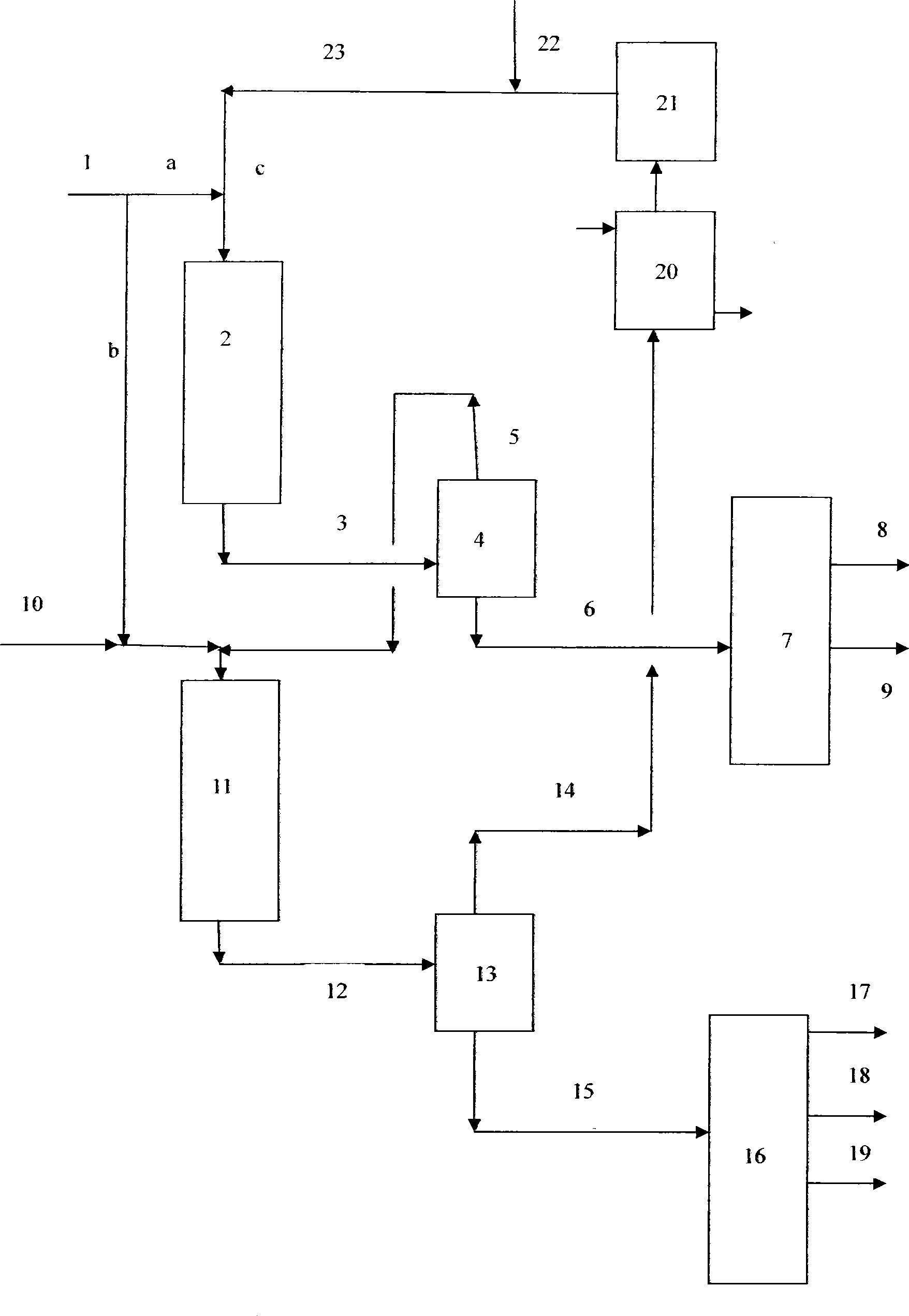

Method used

Image

Examples

Embodiment Construction

[0025] The hydrogenation upgrading catalyst described in step a can be adjusted accordingly according to the different properties of the raw materials. If the content of sulfur and nitrogen impurities in the raw material is low, the hydrogenation upgrading catalyst can be used alone. For the coked diesel fraction, before the hydrogenation upgrading catalyst, the raw material can be contacted with the hydrorefining catalyst to remove part of impurities such as sulfur and nitrogen. Hydrofining catalysts can be conventional hydrofining catalysts, such as various commercial hydrofining catalysts, such as FH-5, FH-5A, FH-98, FH-DS, FH-UDS developed and produced by Fushun Petrochemical Research Institute , 3936, 3996 and other hydrotreating catalysts, or catalysts with similar functions developed by other catalyst companies, such as HC-K and HC-P from UOP, TK-555 and TK-565 from Topsor, and AKZO’s KF-847, KF-848, etc. The hydrogenation upgrading catalyst can be selected according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com