Preparation method of polypropylene resin used for manufacturing medical infusion bottle by injection stretch blow moulding

A polypropylene resin, injection-stretch-blow technology, applied in the field of polypropylene resin preparation, can solve problems such as unsatisfactory anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

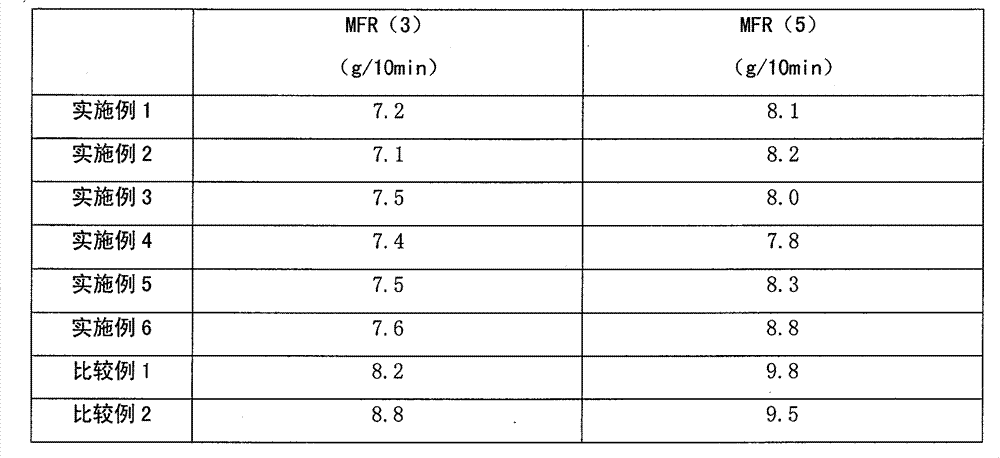

Examples

Embodiment 1~6

[0022] The polypropylene resin base material is uniformly mixed with the additives, and then melted and mixed for granulation to obtain a polypropylene resin product. The melting heating temperature is 200-230° C., and the melting heating time is 2-4 minutes.

[0023] The above-mentioned polypropylene resin base material is a random copolymer of propylene and ethylene, the ethylene content of which is 0.5-4wt%, the melting temperature is 140-165°C, and the melt flow rate is 7.0g / 10min;

[0024] Above-mentioned additive comprises acid absorbing agent, antioxidant A and antioxidant B, wherein:

[0025] The antioxidant A is 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane; the acid absorbing agent is calcium stearate and hydrogenated talc in the same weight portion.

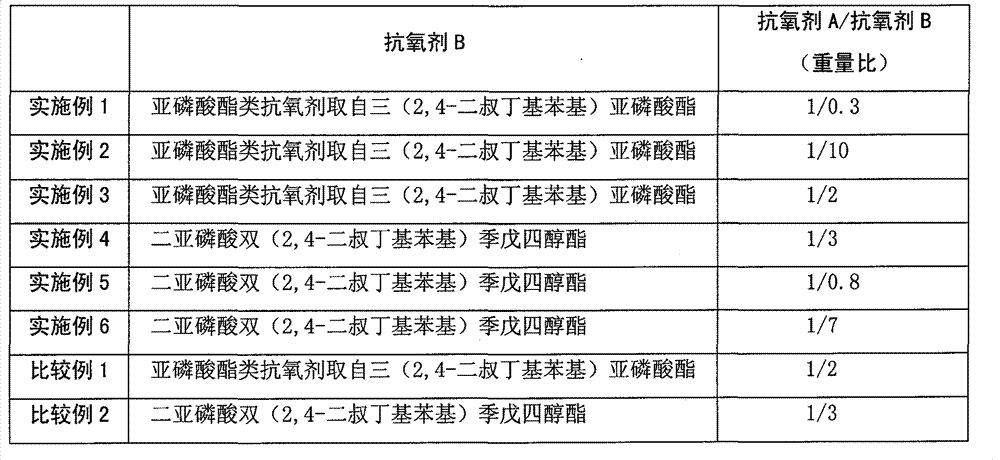

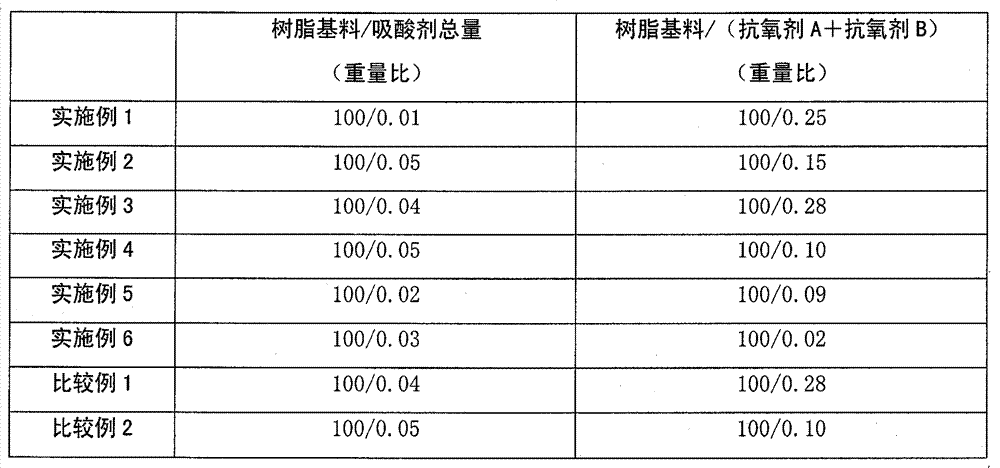

[0026] The concrete antioxidant B of each embodiment is shown in Table 1, and the proportioning of each substance is shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com